Description

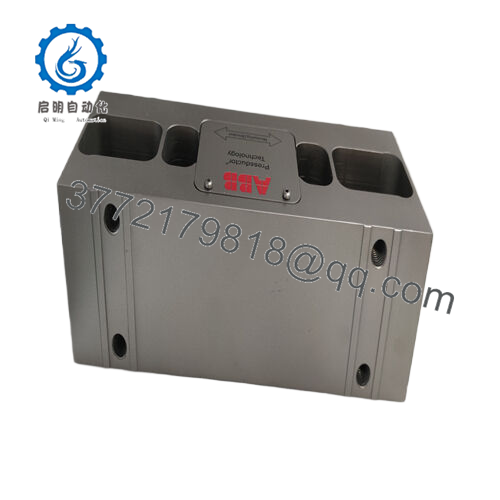

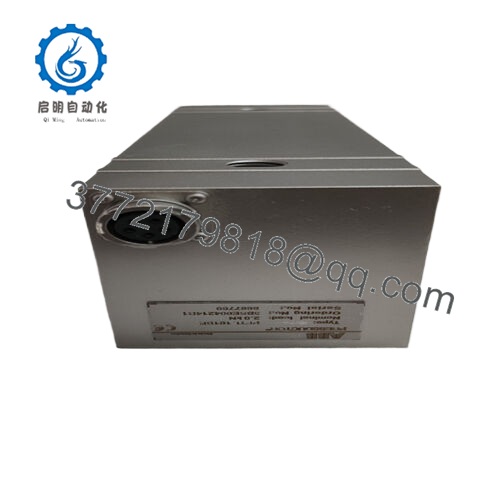

Product Model: ABB PFTL101BE 2.0 kN 3BSE004214R1

Product Brand: ABB

Product Series: PFTL101 / Pressductor PillowBlock family

Product Features:

- 2.0 kN nominal horizontal force measurement using Pressductor technology

- Fixed-cable (BE version) robust in harsh industrial environments

- Excellent overload and transverse force tolerance characteristics

- Stainless steel construction and advanced magnetic sensing, offering long life and minimal drift

Product Role & System Fit

The ABB PFTL101BE 2.0 kN 3BSE004214R1 is a horizontal Pressductor pillow-block load cell designed to measure web or strip tension indirectly via force on a roll. In continuous strip processing lines (paper, coating, film, textile), the module is mounted under a measuring roll; the tension in the web causes a reaction force on the roll supports that the load cell senses. Because it measures the horizontal reaction force (rather than direct tension in the strip), it is less sensitive to misalignment and better suited for continuous, high-speed operations.

In a typical tension control system, the PFTL101BE module is linked to a junction box and then to a tension amplifier or control unit. The amplifier converts the raw (magnetic) signal into a DC or mV output proportional to tension, which then feeds a tension controller or DCS. What makes the ABB PFTL101BE 2.0 kN 3BSE004214R1 especially useful is its compatibility with standard ABB tension control platforms, enabling retrofit or greenfield integration into ABB measurement & analytics systems.

Because it is the “BE” variant, the load cell features a fixed connection cable rather than a detachable connector, which reduces connector-related failures in harsh, vibration-prone environments. In many industrial installations, that reliability is critical, especially when downtime is expensive.

Applications & Industry Context

In practice, the ABB PFTL101BE 2.0 kN 3BSE004214R1 is most commonly used in paper machines, coaters, winders, calenders, film lines, and other web handling systems — anywhere a continuous web is spanned over rolls under tension. The module is especially suited for the dryer section of paper machines, where tension control is delicate and environmental conditions are harsh (heat, dust, moisture).

Paper mills often operate at high speeds with heavy rolls, making direct tension sensors impractical. The Pressductor pillowblock format allows the sensing element to reside in a rigid support, isolating it from direct strip stresses. Operators in such mills often install the PFTL101BE under bearing housings or end plates, measuring forces imposed by web tension in a stable mechanical configuration.

Because its measurement is less intrusive and more robust, the ABB PFTL101BE 2.0 kN is also found in textile lines, metal foil unwinding/winding plants, plastic film lines, converting equipment, and even in some steel strip tension setups where moderate forces are involved. In retrofit projects, engineers often prefer this load cell because it can be mounted without needing to sever the web or adapt the strip path significantly.

Another real-world observation: in many installations, the ABB PFTL101BE remains stable over years, with minimal drift or recalibration required — especially when the surrounding mechanical frame is rigid and free of vibration. This longevity helps justify the upfront cost in energy-intensive and uptime-critical industries.

ABB PFTL101BE 2.0KN 3BSE004214R1

ABB PFTL101BE 2.0KN 3BSE004214R1

Technical Features & Benefits

One of the standout features of ABB PFTL101BE 2.0 kN 3BSE004214R1 is its use of Pressductor® magnetic measurement technology. Unlike strain gauge sensors, Pressductor sensors detect changes in magnetic flux through ferromagnetic cores induced by mechanical stress. This design yields low impedance, high signal strength, and excellent resistance to external electrical interference and grounding issues.

Because the sensing element is not a mechanically deforming beam, the measurement is free from hysteresis and fatigue associated with repeated load cycling, giving virtually unlimited load cycles. Over years of continuous operation, drift is minimal.

In terms of overload capacity and direct-to-transverse force tolerance: the PFTL101BE 2.0 kN is rated to withstand significant overloads (often up to 10 kN or more, depending on the variant) and high transverse (side) loads without performance degradation. This robustness is especially beneficial during web breaks, sudden tension surges, or mechanical shocks common in industrial process lines.

The stainless steel housing ensures durability and resistance to corrosion, and the “BE” model’s fixed cable makes the connection less vulnerable to disconnection or ingress under vibration or moisture. The unit is typically compensated over a temperature range to reduce thermal drift, ensuring stable readings even when ambient temperatures vary.

From a mechanical viewpoint, the device is machined from a solid block, giving structural stiffness and minimal distortion. This ensures that alignment errors or mounting imperfections minimally affect measurement accuracy.

In summary, the ABB PFTL101BE 2.0 kN 3BSE004214R1 offers a compelling mix of long-term stability, overload resilience, immunity to interference, and robust mechanical design — ideal for demanding web tension measurement applications.

Technical Specifications Table

| Specification | Detail |

|---|---|

| Product Model | ABB PFTL101BE 2.0 kN 3BSE004214R1 |

| Type / Role | Horizontal Pressductor PillowBlock Load Cell |

| Nominal Load (F_nom) | 2.0 kN in measuring direction |

| Overload Capacity (F_max) | Up to ~10 kN (varies per datasheet and margin) |

| Transverse Force Tolerance | Up to ~30 kN (per variant table) |

| Housing Material | Stainless steel (SIS 2383 / equivalent) |

| Cable / Connection | Fixed cable (BE variant) |

| Temperature Compensated Range | Typically –10 °C to +80 °C (varies by design) |

| Operating Temperature | –10 °C to +105 °C (storage / extremes) |

| Deflection under Load | ~0.015 mm (typical for PFTL series) |

| Spring Constant | ~130 kN/mm (for 2.0 kN B/BE series) |

| Accuracy Class | ±0.5 % (linearity, including hysteresis, repeatability) |

| Dimensions / Mounting | PillowBlock with standard mounting holes (see ABB drawings) |

Installation & Maintenance Insights

Installing the ABB PFTL101BE 2.0 kN 3BSE004214R1 properly is key to realizing its performance in the field. Because the load cell measures reaction force on a support, mechanical alignment and rigid mounting are vital. Mounting surfaces and adapter plates should be flat (preferably within 0.05 mm deviation) and rigid to avoid introducing bending or unintended loads.

The module is often bolted between the bearing housing and its support block, using six screws (four on one side, two on the other). Care must be taken to tighten uniformly and torque to specification so as to avoid pre-stressing the cell.

Cable routing matters: keep the fixed cable away from high-voltage conductors, avoid sharp bends, protect against chafing, and ensure strain relief. The BE variant’s fixed cable reduces the risk of connector faults but still needs environmental protection. In installations with significant vibration or heat, conduit or flexible protective sleeves may help extend cable life.

When commissioning, it is common to perform zero balancing under no-load conditions, followed by a two-point calibration (zero and known tension). Monitor for drift, noise, or instability during warm-up periods. In web tension systems, ensure that wrap angle, roll geometry, and web path do not introduce asymmetries that the load cell cannot distinguish.

For maintenance, periodic checks of output drift, noise levels, and cable integrity are useful. Many installations build in alarm thresholds to detect when the measured signal deviates abruptly (indicating damage or misalignment). If the system allows, logging diagnostics and residuals can help spot creeping faults before they become critical.

Because the ABB PFTL101BE uses a non-mechanical sensing element, mechanical wear is minimal. Still, over the long term, inspect mounting hardware, connectors, and cable insulation. In dusty or corrosive environments, ensure surfaces remain clean and protective finishes intact.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626