Description

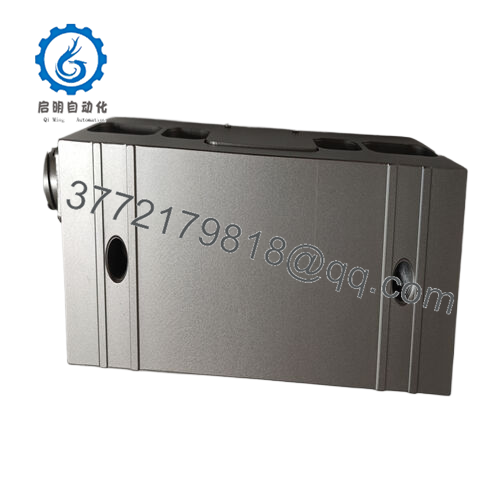

ABB PFTL101B 5.0KN 3BSE004191R1 Product Description:

ABB PFTL101B 5.0KN 3BSE004191R1 is a high-precision strain gauge weighing sensor designed specifically for industrial weighing and force sensing applications. As part of ABB’s trusted measurement and analysis solution portfolio, it seamlessly integrates with ABB’s programmable logic controller (PLC), human-machine interface (HMI), and distributed control system (DCS) to form the core of a reliable force feedback loop. This weighing sensor serves as a critical interface between physical machinery and digital control systems, converting mechanical loads into electrical signals for real-time processing, analysis, and action.

PFTL101B 5.0KN 3BSE004191R1

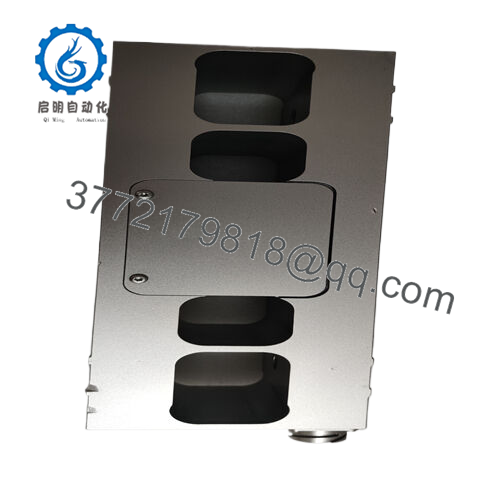

For engineers and system integrators, its value lies in the ability to achieve ± 0.05% accuracy within a measurement range of 5.0 kN, ensuring compliance with strict industry standards. Its sturdy aluminum alloy structure and sealing design (IP67 protection level) enable it to resist water, dust, and corrosive substances, while its compact design (only [size] millimeters) allows it to be installed in small spaces – making it ideal for retrofitting existing machinery. Whether used for static weighing (such as tracking warehouse inventory) or dynamic force monitoring (such as lifting equipment), PFTL101B can simplify integration in complex automation architectures, shorten debugging time, and improve system reliability.

PFTL101B 5.0KN 3BSE004191R1

PFTL101B 5.0KN 3BSE004191R1

Main features and advantages:

PFTL101B 5.0KN 3BSE004191R1 performs excellently in terms of functional performance, with fast response time and the ability to capture transient loads without distortion. Its built-in temperature compensation function ensures measurement stability over a wide operating temperature range (-30 ° C to+70 ° C), which is crucial for applications with fluctuating environmental conditions. The high overload capacity (150% of rated load) of this weighing sensor provides a safe buffer against unexpected impacts, while its anti fatigue performance (10 million load cycles) ensures its service life in high-frequency environments such as packaging lines or cargo handling.

In terms of hardware, its through-hole installation design allows for flexible installation – whether directly bolted onto machinery or integrated into customized fixtures. Shielded cables with M12 connectors can minimize electromagnetic interference (EMI), which is a common challenge for high-energy equipment in factories. The compatibility with industry standard protocols, such as Modbus RTU implemented through optional transmitters, ensures seamless integration with third-party systems, making it a flexible choice for multi vendor settings.

Long term reliability is further improved through its creep resistance, which enables it to maintain accuracy even under sustained loads – crucial for applications such as tension control in textile manufacturing. Engineers appreciate its pre calibrated output (nominal 2.0mV/V), which reduces on-site calibration work, while traceable NIST certification adds credibility to industries with strict quality control, such as pharmaceuticals.

PFTL101B 5.0KN 3BSE004191R1

Technical specifications:

Model PFTL101B 5.0KN 3BSE004191R1

Brand ABB

Type: Strain Gauge Weighing Sensor

Rated load 5.0 kN (500 kgf)

Accuracy level OIML R60 C3

Non linearity ± 0.03% rated load

Lag ± 0.03% rated load

Temperature range -30 ° C to+70 ° C (working); -40 ° C to+80 ° C (storage)

Protection level IP67 (sealed)

Installation method: fixed with through-hole bolts

Cable length 5 meters (shielded, PVC insulated)

Output signal 2.0mV/V ± 10% (nominal)

150% of the rated load for safe overload

Electrical connection 4-wire system (power input, signal output)

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

Application areas:

This device is designed for durability and reliability, and is indispensable in fields such as manufacturing, material handling, and process automation. For example, on an automotive assembly line, it ensures that the robotic arm applies exactly 5.0 kilonewtons of force during component installation – avoiding product failures caused by insufficient tightening and preventing component damage caused by excessive tightening. In steel production, when the bridge crane lifts heavy steel coils, PFTL101B monitors the load in real time to prevent equipment damage or safety hazards caused by overload accidents.

Mining operations also rely on this weighing sensor to measure the tension of the conveyor belt, ensuring smooth material flow and detecting abnormal situations such as deviation or sudden weight changes. Its compatibility with ABB automation systems makes it the preferred choice for engineers designing closed-loop control systems, such as in food processing plants where it can adjust the filling weight of products on the packaging line. By addressing challenges such as environmental interference, mechanical stress, and long-term drift, PFTL101B 5.0KN 3BSE004191R1 can maintain stable performance under harsh conditions from dust warehouses to high humidity environments.

Related products:

ABB PFTA101C – Signal conditioning module, used for amplifying and filtering the mV/V output of weighing sensors, compatible with ABB’s AC 800M PLC.

ABB PFTL1101 2.5KN – Suitable for lighter applications with the same mechanical dimensions.

ABB PCM602- Multi channel process controller integrated with PFTL101B for real-time load monitoring and alarm triggering.

ABB PSTX30-600-70- Soft starter, used in conjunction with weighing sensors in conveying systems to achieve smooth starting force management.

ABB TA800- Temperature transmitter, suitable for environments that require external sensor input for thermal compensation.

ABB PFTL102B 10KN – high-capacity version, suitable for heavy-duty lifting applications, using the same calibration protocol.

ABB PM510-ETH – Ethernet gateway module, used to transmit load data to the cloud monitoring platform.

Installation and maintenance:

Before installation, ensure that the installation surface is flat and free of debris to avoid measurement errors caused by eccentric loading. Use high-strength bolts (grade 8.8 or above) and tighten according to the manufacturer’s specifications (usually [X] N · m) to securely fix PFTL101B. Separate cables from high-voltage lines during wiring to reduce electromagnetic interference; In noisy environments, it is recommended to use shielded conduits. Ground the weighing sensor and related electronic devices to a common grounding point to prevent grounding loops.

For maintenance, it is recommended to conduct visual inspections every quarter to check for physical damage, loose connections, or corrosion on installed hardware. Use a multimeter to verify the output impedance and bridge voltage of the weighing sensor, and compare them with the factory specifications in the data sheet. Perform calibration checks every 12 months using known reference weights (such as certified test loads) to ensure accuracy. If the system is used in a high vibration environment, the inspection frequency should be increased to detect early signs of cable wear or mechanical fatigue. Regularly update the firmware of the connected transmitter or controller to utilize improved noise filtering or diagnostic functions.

Other product models of ABB brand:

ABB PM861AK01 3BSE018157R1

ABB PM633 3BSE008062R1

ABB Al630 3BHT300011R1

ABB 3BHL000986P3003 5SDF1645L0006

ABB 3BHB004744R0010

ABB 3BSE023732R1

ABB PU519 3BSE018681R1

ABB AO2000 LS25

ABB 1SDA053999R1

ABB CI854BK01 3BSE069449R1

ABB DI830 3BSE013210R1

ABB PM645B

ABB 3BHE035301R0001 UNS 0121 A-Z,V1

ABB 3BHE035301R1002 UNS 0121A-Z,V1

ABB AO810V2

ABB 5SHY4045L0006 3BHB030310R0001 3BHE039203R0101 GVC736CE101

ABB XVC517AE10 3BHB004744R0010

ABB UFC760BE1042 3BHE004573R1042

ABB UFC760BE141 3BHE004573R0141

ABB NAVIGATOR 600 V20

ABB TP867 3BSE043664R1

ABB 1SFA616502R3001

ABB GDC801B101 3BHE051592R0101

ABB DSAX 452 5712289-A

ABB REM620

ABB UFC760BE142 3BHE004573R0142

ABB 3BHL000385P0101 5SGX0845F0001

ABB REM545BG229AABA 1MRS110025-001

ABB UNITROL1010

ABB 3BHE004573R0143 UFC760BE143

ABB REF615 HBFFAFAGANB6ANA1XG

ABB CI867AK01 3BSE092689R1

ABB REM611HCAACB2NN1XE

ABB GJR5252100R2201 07KT94-S

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626