Description

Real-World Use & Application Scenarios

Accurate force measurement is fundamental in industries where load control directly impacts product quality and safety. The ABB PFTL101B 5.0KN 3BSE004191R1 load cell is designed for heavy-duty industrial applications such as paper manufacturing, material handling, and process automation, where it effectively measures tension and compression forces. This robust sensor is commonly installed under roll bearings in paper machines, calenders, coaters, and winders to monitor web tension, a critical factor in ensuring product consistency and preventing material breakage.

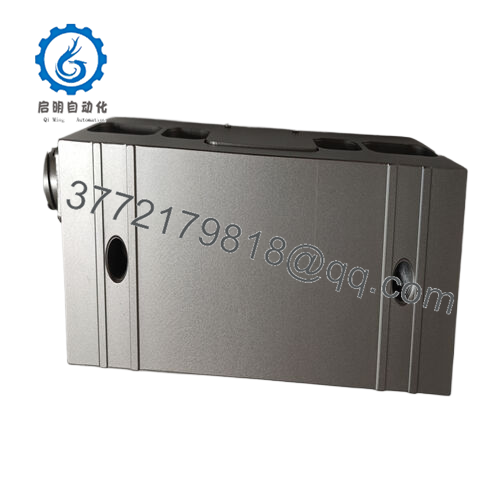

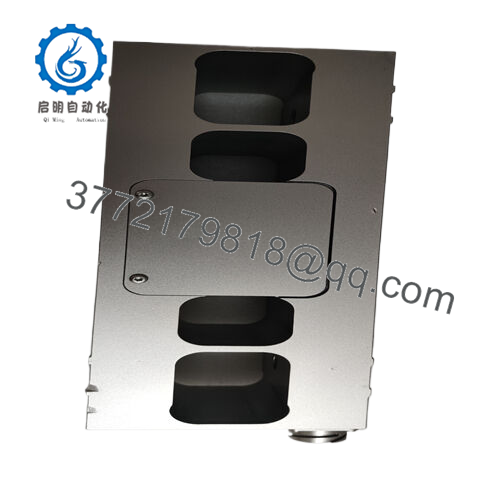

PFTL101B 5.0KN 3BSE004191R1

PFTL101B 5.0KN 3BSE004191R1

PFTL101B 5.0KN 3BSE004191R1

The ABB PFTL101B 5.0KN 3BSE004191R0101 is well-suited for dynamic operating environments featuring rapid load changes and high mechanical stress. Its resilient construction and precise sensing capabilities allow operators to maintain tight control over processes in industries such as packaging, textiles, and converting operations. Because it can handle significant lateral loads and shock, this load cell delivers reliability where robust force feedback is essential.

Product Introduction & Positioning

The ABB PFTL101B 5.0KN 3BSE004191R0101 is a horizontal pressductor pillow-block load cell engineered using ABB’s patented Pressductor technology. It measures forces in the direction parallel to the mounting surface and converts mechanical stress into precise electrical signals. Part of ABB’s comprehensive portfolio of force transducers, this sensor is specifically optimized for the paper industry but equally applicable wherever accurate load or tension measurement is required.

Positioned for integration into ABB’s distributed control systems, the PFTL101B 5.0KN provides digital or analog output signals with high accuracy, enabling tight process control. Its spring constant and mechanical properties suit applications demanding minimal deflection and high repeatability. System designers and engineers value this load cell for its durability, accuracy class, and compatibility with ABB control and monitoring architectures.

Key Technical Features & Functional Benefits

The ABB PFTL101B 5.0KN offers a rated nominal load capacity of 5.0 kN (approximately 1125 lbf), with a permitted lateral load capacity of 30 kN, providing robustness against side forces common in industrial operations. It features minimal deflection (0.015 mm) under load, ensuring stable and repeatable readings with an accuracy of ±0.25% and repeatability of ±0.1%.

Constructed from high-strength stainless steel and alloy steel, the load cell withstands harsh environmental conditions with an IP67 protection rating, making it dust-tight and water-resistant. Operating temperature ranges from -10°C to +80°C, supporting reliability in various climatic conditions. The output signal is typically 2.0 mV/V analog, compatible with standard industrial data acquisition systems.

Its design includes high resistance to vibration (2g from 10 Hz to 500 Hz) and shock (30g, 11 ms), ensuring longevity and stable operation under mechanical stress. The ABB PFTL101B 5.0KN supports straightforward installation via pillow block mounting and is ideal for retrofit or new system implementations.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | PFTL101B 5.0KN 3BSE004191R0101 |

| Brand | ABB |

| Product Type | Horizontal Pressductor Pillow-block Load Cell |

| Rated Load (Nominal) | 5.0 kN (1124.5 lbf) |

| Allowed Lateral Load | 30.0 kN (6744 lbf) |

| Permitted Overload | 25.0 kN |

| Deflection | 0.015 mm |

| Spring Constant | 325 kN/mm |

| Accuracy Class | ±0.25% |

| Repeatability | ±0.1% |

| Material | Stainless steel & alloy steel |

| Protection Class | IP67 |

| Operating Temperature | -10°C to +80°C |

| Storage Temperature | -40°C to +95°C |

| Output Signal | 2.0 mV/V analog |

| Vibration Resistance | 2g (10 to 500 Hz) |

| Shock Resistance | 30g (11 ms) |

Related Modules or Compatible Units

ABB PFTL101A 2.0KN – Smaller capacity pillow-block load cell for lighter forces.

ABB PFTL101BE 10.0KN – Higher capacity version for heavier industrial loads.

ABB PFTL101BER 20.0KN – Acid-resistant model for wet or corrosive environments.

ABB PFTL101 Calibration Kit – For maintaining measurement accuracy over time.

ABB PFXC141 Control Unit – Interface unit for processing signals from load cells like PFTL101B.

Installation Notes & Maintenance Best Practices

Install the ABB PFTL101B 5.0KN under roll bearings with appropriate mounting brackets to ensure accurate force transfer and minimal external mechanical interference. Proper alignment and secure fastening are critical to maintain measurement precision. Ensure wiring uses shielded cables and robust connectors to avoid electrical noise sensitivity.

Routine maintenance involves periodic calibration checks using recommended calibration kits to maintain measurement accuracy. Inspect the load cell for signs of corrosion or mechanical wear, particularly in harsh operational environments. Regular cleaning and verification of signal integrity help avoid data drift and prolong service life.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626