Description

Real-World Use & Application Scenarios

Force measurement underpins reliable tension control in numerous industrial processes, particularly in paper manufacturing, packaging, and material handling. The ABB PFTL101A 1.0KN 3BSE004166R1 load cell is ideal for applications requiring precise measurement of forces such as those generated in web tension or mechanical equipment load monitoring. Typically installed under roller bearings in machines, it accurately captures horizontal forces that reflect dynamic tension, enabling operators to maintain product quality, prevent breakage, and optimize manufacturing throughput.

Industries with demanding operational requirements benefit from the PFTL101A 1.0KN‘s ability to handle rapid load changes and resist mechanical stresses while delivering consistent readings. It supports processes in textile production, steel processing, and converting operations where tight tension control translates to reduced waste and enhanced process efficiency. The load cell is a central measurement component in automated systems monitoring force vectors vital to overall plant health and safety.

Product Introduction & Positioning

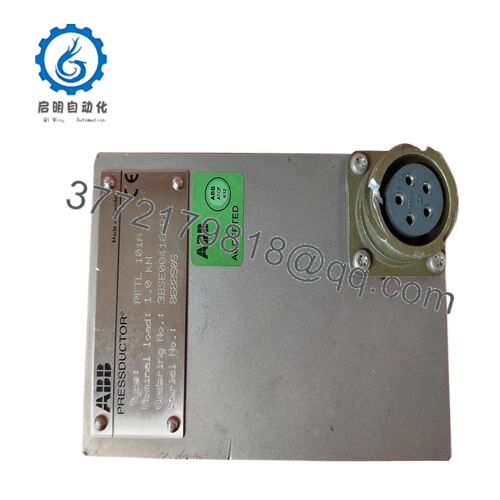

The ABB PFTL101A 1.0KN 3BSE004166R1 is a pressductor pillow-block load cell based on ABB’s advanced magnetoelastic measurement technology. It measures force parallel to its mounting surface by converting mechanical strain into an electrical signal proportional to the applied load. Part of ABB’s renowned PFTL 101 series, this sensor is optimized for horizontal force measurement with general applicability in force and tension control systems.

Designed for integration with ABB’s control units and distributed control systems, the PFTL101A 1.0KN delivers reliable, high-fidelity analog output signals used by automation controllers to regulate process dynamics. Its compact and robust construction supports installation in challenging industrial environments, while maintaining tight measurement tolerances and stability. Engineers rely on it for seamless compatibility and long-term operational confidence.

Key Technical Features & Functional Benefits

The ABB PFTL101A 1.0KN load cell has a nominal capacity of 1.0 kN (approximately 225 lbf) with a permissible transverse force capacity of 10 kN and an overload rating of 2.5 kN, providing substantial robustness against off-axis forces and transient loads. It features minimal deflection of 0.015 mm under load, guaranteeing consistent measurement without significant bending or distortion.

PFTL101A 1.0KN 3BSE004166R1

PFTL101A 1.0KN 3BSE004166R1

Manufactured from stainless steel, the sensor offers a high degree of corrosion resistance and durability, with an IP67-rated enclosure protecting it from dust and water ingress. It operates effectively within a temperature range of -10°C to +80°C, suitable for diverse industrial climates. The output signal typically measures 2 mV/V, compatible with standard process controllers and signal conditioners.

The load cell’s spring constant of 125 kN/mm ensures accurate force-to-deflection conversion for stable and repeatable readings across long operational periods. Its design supports easy installation using pillow-block mounts and standard connection interfaces, aiding maintenance and system upgrades.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | PFTL101A 1.0KN 3BSE004166R1 |

| Brand | ABB |

| Product Type | Pressductor Pillow-Block Load Cell |

| Nominal Capacity | 1.0 kN (225 lbf) |

| Permitted Transverse Force | 10 kN (2,250 lbf) |

| Overload Capacity | 2.5 kN |

| Deflection | 0.015 mm |

| Spring Constant | 125 kN/mm |

| Accuracy Class | ±0.5% |

| Repeatability | ±0.05% |

| Material | Stainless Steel |

| Protection | IP67 |

| Operating Temperature Range | -10°C to +80°C |

| Output Signal | 2 mV/V analog signal |

Related Modules or Compatible Units

ABB PFTL101B 5.0KN – Higher capacity pillow-block load cell for larger industrial force measurements.

ABB PFTL101AE – Fixed cable variant designed for harsh or corrosive environments.

ABB PFXC141 – Signal conditioning interface unit for precise load cell output processing.

ABB Control Units AC 800M – Automation controllers integrating load cell signals for process control.

ABB PM867 – Redundant power and control modules complementing load cell systems.

Installation Notes & Maintenance Best Practices

Install the ABB PFTL101A 1.0KN load cell with secure pillow-block mounting to transfer load accurately while minimizing mechanical disturbances. Use shielded, high-quality cabling and connectors to reduce noise and ensure signal integrity. Verify correct alignment during installation to avoid measurement errors caused by angular loads.

Routine maintenance demands inspection for signs of physical wear, corrosion, or connection issues. Regular calibration validation ensures sustained accuracy and system reliability. Keeping spare load cells and calibration tools onsite ensures minimal downtime and quick recovery from any operational issues.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626