Description

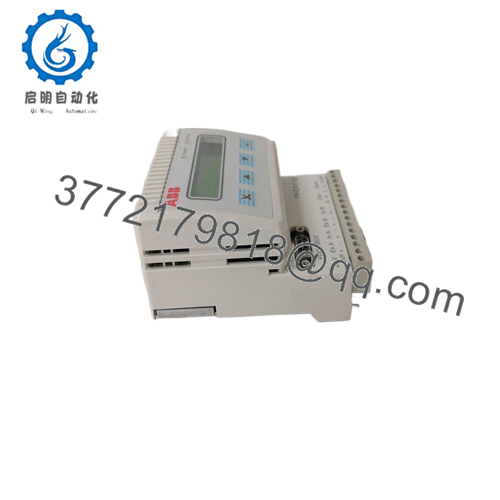

ABB PFEA112-20 is a high-performance control unit designed specifically for ABB drive systems in the industrial automation field. It serves as the ‘central brain’ for motor control, interacting with the motors, sensors, and other components within the drive system through interfaces. This unit supports multiple communication protocols, including Profibus DP and CANopen, and can be smoothly integrated with a wide range of control systems and field devices.

PFEA112-20

This control unit is equipped with advanced algorithms and processing capabilities, which can accurately adjust the speed, torque, and direction of the motor. It continuously monitors feedback from sensors (such as encoders) to ensure accurate motor operation and makes real-time adjustments as needed. The built-in diagnostic function continuously checks the health status of the unit itself and connected components, detecting issues such as overcurrent, overvoltage, or communication failures. Once an abnormal situation is detected, it will trigger an alarm and activate protective measures to prevent damage to the motor and other equipment.

PFEA112-20

Technical specifications:

Model PFEA112-20

Brand ABB

Type Drive System Control Unit

Input voltage 24 V DC

Working temperature range -25 ° C to 55 ° C

Installation method: DIN rail

Size 150 x 100 x 60 mm

Weight 0.6 kg

Interface/Bus Profibus DP, CANopen

Certification CE, RoHS

Supports protocols Profibus DP and CANopen

Typical power consumption of 12 W

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818

PFEA112-20

Main features and advantages:

Its precise motor control capability can optimize the performance of motor driven equipment, reduce energy consumption and wear. By ensuring accurate speed and torque regulation, it improves product quality during the manufacturing process, as stable motor operation can bring more precise production results.

Multi protocol support simplifies system integration and reduces the time and cost required to connect different devices and systems. It achieves seamless communication between the control unit, motor, and advanced control system, facilitating centralized monitoring and control. The built-in diagnostic function enhances system reliability by quickly identifying and solving problems, minimizing unexpected downtime and lowering maintenance costs.

The compact design and convenient installation of ABB PFEA112-20 make it an ideal choice for new automation projects and system upgrades. Its sturdy structure and wide operating temperature range ensure reliable operation in harsh industrial environments, capable of withstanding vibration, dust, and electrical interference. This makes it a cost-effective and durable solution, bringing high return on investment to industrial applications.

PFEA112-20

Application areas:

In manufacturing, it is used to control the motors of CNC machine tools, robotic arms, and conveyor systems. For example, in a metal processing plant, it precisely controls the speed and torque of the CNC machine tool motor, achieving precise machining operations and improving production efficiency.

In the field of logistics and warehousing, this control unit is used to manage the motors of Automated Guided Vehicles (AGVs) and overhead cranes. It ensures the smooth and reliable operation of these vehicles, optimizes material handling processes, and improves warehouse productivity.

In the food and beverage industry, ABB PFEA112-20 controls the motors of packaging machines, mixers, and other production equipment. It helps maintain consistent production speed and product quality, ensuring compliance with strict industry standards. Whether in industries that require high precision or in harsh operating environments, this control unit can provide stable and reliable performance.

Related products:

ABB PFEA113-20: With stronger processing capabilities and additional communication interfaces, it is suitable for more complex and data intensive motor control applications.

ABB PFEA111-20: With basic control functions, it provides cost-effective solutions for small projects or tasks that do not require high motor control requirements.

ABB PFEA122-20: The control unit integrates advanced safety features to provide additional protection for personnel and equipment in high-risk industrial environments.

ABB PFEA112-30: With different built-in functions and software features, it is designed for specific industry applications that require customized motor control solutions.

ABB PFEA114-20: Better compatibility with emerging industrial communication standards, preparing for technological upgrades in automation systems.

Installation and maintenance:

Before installing the ABB PFEA112-20 control unit, it is essential to verify the compatibility of the communication protocol with existing equipment and systems. Ensure that the input voltage supply is stable and within the specified range to avoid electrical issues. When installing the unit on the DIN rail, ensure that it is securely fixed and has sufficient space for proper ventilation to prevent overheating.

For daily maintenance, it is necessary to regularly check the status indicator lights on the control unit to monitor its operating status. Regularly backup control programs to prevent data loss caused by system failures. Check for signs of wear, damage, or loose connections in communication cables and connectors, as these issues may interrupt communication and affect motor control. Update the firmware of the unit in a timely manner according to ABB’s release plan to benefit from the latest features, performance improvements, and security patches.

Other ABB product models:

ABB 206-00212

ABB 216AB61 HESG324013R101

ABB 216AB61 HESG324013R0101

ABB 216DB61 HESG324063R100/H

ABB 216DB61 HESG324063R100/H

ABB 216DB61 HESG324063R0100

ABB 216EA61B HESG448230R1/G

ABB 216EA62

ABB 216EA62

ABB 216EA62

ABB 216EA62 1MRB150083R1/F

ABB 216MB66 HESG324510M1

ABB 216NG62A HESG441634R1/K HESG216876

ABB 216NG63A HESG441635R1 HESG216879/K

ABB 216V62a HESG324442R13/B

ABB 216VC62a HESG324442R112/F

ABB 216VC62a HESG324442R112/F

ABB 216VC62a HESG324442R112/F

ABB 216VC62a HESG324442R13/B

ABB 216VC62A HESG324442R112/F

ABB 216VC62A HESG324442R13

ABB 216VC62A HESG324442R13

ABB 216VC62A HESG324442R13

ABB 216VC62a/P1000 HESG324442R112

ABB 2CSG299893R4052

ABB 2CSG299893R4052

ABB 2UBA00004416R0007

ABB 3AUA0000036521

ABB 3AUA0000110430

ABB 3BDS005799R1 PM665

ABB 3BHB003688R0101

ABB 3BHB003688R0101

ABB 3BHB003689

ABB 3BHB003689

ABB 3BHB003689

ABB 3BHB003689 3BHB003688R0101

ABB 3BHB005243R0105

ABB 3BHB005243R0106 KUC755AE106

ABB 3BHB005243R0117

ABB 3BHB005245R0101

ABB 3BHB005922R0001

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626