Description

Real-World Use & Application Scenarios

The ABB PFCA401SF 3BSE024387R4 is a precision control unit widely employed in heavy industries such as metal rolling, non-ferrous metal processing, and industrial automation production lines. Its primary application is in strip tension measurement and control, crucial for processes like hot and cold rolling, skin passing, foil rolling, pickling, annealing, and plating. This module addresses the critical need to accurately measure and manage strip tension, helping industries reduce material waste and improve product quality.

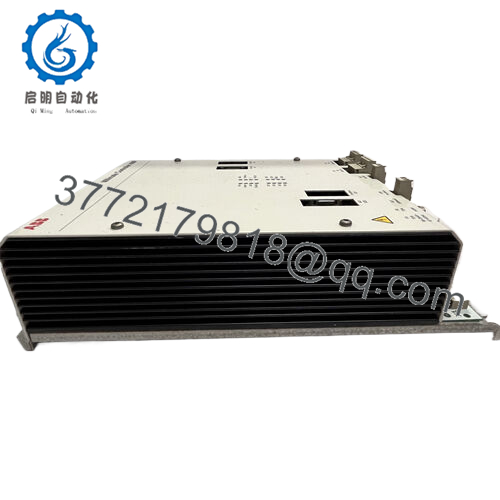

- PFCA401SF 3BSE024387R4

In demanding manufacturing environments, precise control of tension ensures consistent strip thickness and surface finish, directly impacting yield and operational efficiency. The ABB PFCA401SF 3BSE024387R4 excels in environments requiring precise sensor integration, reliable data processing, and flexible input/output configurations that adapt to complex mechanical setups. Its role is fundamental in industrial automation scenarios focused on high-end production quality and real-time process optimization.

Engineers and operators rely on this control unit for its adaptability to different measurement modes, comprehensive fault diagnostics, and seamless interconnection with multiple devices along production lines, making it a trusted solution in control systems where accuracy and reliability are paramount.

Product Introduction & Positioning

The ABB PFCA401SF 3BSE024387R4 is an advanced automation control module designed specifically for strip tension measurement under the Millmate 400 family. Equipped with a high-performance processor, it handles large volumes of control commands and sensor data, guaranteeing real-time performance and operational stability.

This control unit supports multiple analog and digital inputs/outputs, making it highly configurable for different mechanical layouts in rolling mills and metal processing lines. It offers flexible filter time setting from 5 to 2000 milliseconds, easily adapting to diverse measurement environments. With integrated Ethernet connectivity and serial interfaces (RS-232, RS-485), it enables efficient communication and coordination with other control units in complex automation setups.

The module’s design reflects ABB’s commitment to precision control and robust construction, facilitating straightforward user operation through intuitive setup processes and built-in diagnostic systems.

Key Technical Features & Functional Benefits

The ABB PFCA401SF 3BSE024387R4 features a powerful processor that rapidly processes control commands and data, enhancing real-time automation capabilities. Its group-insulated I/O design ensures reliable signal integrity with fast step response (5 ms 0-90%), important for precise tension measurement.

Inputs include configurable 2 or 4 analog channels for load cell signals, while outputs comprise 4 analog channels in voltage or current form, plus 8 digital inputs and 8 digital outputs enabling versatile control and signal management. This configuration flexibility supports integration with multiple units and wide-ranging mechanical arrangements.

Built-in self-diagnostic functions continuously monitor sensor conditions and system faults, delivering high measurement accuracy and system reliability. The module supports customizable engineering units such as Newtons, kiloNewtons, metric tons, pounds, and tons, accommodating regional preferences and application needs.

Industrial-grade IP20 protection and operation across a wide temperature range (0 to +70°C) ensure the module’s endurance in harsh factory environments, while power supply options spanning 85 to 264 V AC provide broad compatibility.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | PFCA401SF 3BSE024387R4 |

| Brand | ABB |

| Product Type | Automation Control Unit (Millmate 400) |

| Power Requirements | 85–264 V AC |

| Power Consumption | Approx. 1400 VA |

| Input Voltage Supply | 24 V DC, 0.5 A for external devices |

| Operating Temperature Range | 0 to +70 °C |

| Storage Temperature Range | -40 to +70 °C |

| Dimensions (HxWxD) | 380 x 235 x 90 mm |

| Weight | Approx. 5 kg |

| Analog Inputs | 2 or 4 for load cell signals |

| Analog Outputs | 4 (voltage or current configurable) |

| Digital Inputs | 8 (divided into two groups of 4) |

| Digital Outputs | 8 (divided into two groups of 4) |

| Communication Interfaces | 2x RJ45 Ethernet, 2x RS-232, 1x RS-485, optional Profibus |

| Protection Level | IP20 |

| Certifications | ATEX, IECEx, UL Class I Div 2 |

Related Modules or Compatible Units

PPD239 A1106 – Excitation control unit complementing tension measurement systems.

S-093H 3BHB009885R0002 – High impulse phase module compatible with power system controls.

REG216 – Numerical protection relay frequently integrated for system safety.

BMS611B06 – Circuit protection module used alongside tension control units to ensure electrical safety.

PU519 3BSE018681R1 – Real-time accelerator module enhancing control speed in automation setups.

DO810 3BSE008510R1 – Digital output module for controlling actuators in processing lines.

Installation Notes & Maintenance Best Practices

Install the ABB PFCA401SF 3BSE024387R4 in a well-ventilated control cabinet with sufficient clearance for wiring and heat dissipation. Ensure proper grounding and electromagnetic shielding to maintain signal integrity and reliable communication across the plant network.

Routine maintenance includes regular visual inspections and cleaning to prevent dust accumulation on ventilation paths. Periodically validate sensor inputs and outputs, update firmware through USB or network interfaces, and respond promptly to self-diagnostic alerts to maintain system accuracy and uptime. Proper calibration checks and replacement of worn components ensure sustained measurement precision.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626