Description

Real-World Use & Application Scenarios

In advanced industrial automation and control systems, a versatile and high-capacity input/output module is essential for managing diverse digital and analog signals. The ABB PCD232A 3BHE022293R0101 serves this purpose in sectors such as manufacturing, power generation, chemical processing, and water treatment plants. It enables operators to monitor and control numerous discrete and analog signals with precision, ensuring seamless execution of complex process automation tasks.

PCD232A 3BHE02293R0101

PCD232A 3BHE02293R0101

This module is widely integrated into distributed control systems (DCS) where flexibility and reliability are paramount. The ABB PCD232A supports critical control applications, including temperature regulation, pump and motor control, safety interlocks, and status monitoring. By providing multiple interfaces and redundancy features, it enhances system stability and responsiveness in demanding industrial environments.

Product Introduction & Positioning

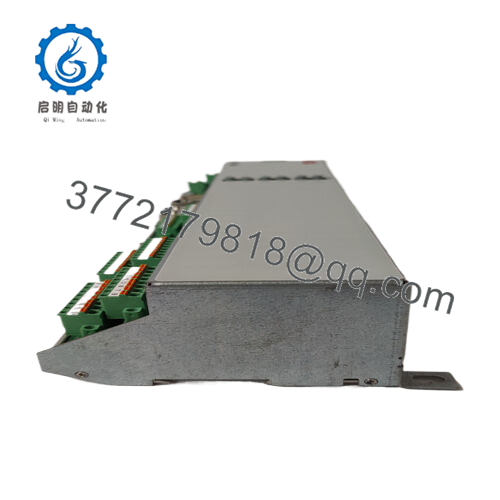

The ABB PCD232A 3BHE022293R0101 is a high-performance combined input/output module from ABB’s PEC80-CIO series. It features 16 relay outputs and 12 digital control inputs supporting 24V or 48V signals, and three analog inputs and outputs with ±10V and ±20mA ranges. Designed for modular installation, the unit supports two independent 24V polling power supplies and multiple communication interfaces, including 4-port Ethernet switch, RS232, RS485, CAN, and optical links.

Positioned as an integral building block in ABB’s automation systems, the PCD232A enhances control system capability by handling a broad array of signals with high accuracy and operational redundancy. Its embedded watchdog function improves system reliability by monitoring module health and preventing faults. Engineers and integrators value its flexible interface options and robust communications for scalable automation architectures.

Key Technical Features & Functional Benefits

The ABB PCD232A offers extensive input/output capabilities, with 12 isolated digital control inputs and 16 relay outputs rated for 10A switching at 250 VAC. Its analog interfaces include three inputs selectable for ±10V or ±20mA ranges and three ±10V analog outputs, enabling diverse signal processing.

Communication is facilitated through multiple channels: four 10/100 Mbps Ethernet ports, RS232, RS485 supporting CAN open and Modbus protocols, and three optical fiber links ensuring high-speed data transmission with robust noise immunity. Its redundant power design and watchdog timer enhance operational stability and fault tolerance.

The module fits in standard control racks with dimensions approximately 152 mm by 383 mm by 17 cm and weighs about 2.5 kg. It operates reliably in temperatures from -25°C to +70°C and humidity levels from 5% to 95% at 40°C, making it appropriate for varied industrial conditions.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | PCD232A 3BHE022293R0101 |

| Brand | ABB |

| Product Type | Combined Input/Output Module |

| Relay Outputs | 16 channels, 10A, 250 VAC |

| Digital Control Inputs | 12 channels, 24/48 V |

| Analog Inputs | 3 channels, ±10V or ±20mA |

| Analog Outputs | 3 channels, ±10V |

| Power Supplies | Two independent 24V polling |

| Communication Ports | 4 Ethernet, RS232, RS485, CAN, Optical fiber |

| Operating Temperature | -25°C to +70°C |

| Weight | 2.5 kg |

| Dimensions (WxHxD) | 152 mm × 383 mm × 170 mm |

| Humidity Range | 5% to 95% (at 40°C) |

Related Modules or Compatible Units

ABB PFEA113-20 – Tension electronics module compatible with PCD232A integration.

ABB PCD231B101 – Excitation control module often used with combined I/O units.

ABB CP405 – Ethernet communication processor suitable for networked control systems.

ABB KUC711AE – Gate power supply unit complementing control applications.

ABB TB850 – Temperature transmitter for input signal conditioning.

Installation Notes & Maintenance Best Practices

Install the ABB PCD232A in a well-ventilated control enclosure, ensuring secure rack mounting and proper cable management. Connect power supplies in accordance with ABB’s redundant 24V requirements for improved reliability. Use shielded communication and signal cabling to prevent interference.

Maintenance routines include regular visual inspections of connectors and status LEDs for early fault detection. Periodic software diagnostics verify communication integrity and I/O channel performance. Keeping spare modules onsite can reduce downtime during replacement or upgrades.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626