Description

Real-World Use & Application Scenarios

In today’s process industries, control reliability is just as important as throughput. When a chemical plant is pushing batch cycles around the clock, or a power station is balancing fluctuating loads on the grid, downtime is measured in both lost revenue and safety risk. That’s where products like the ABB PCD231B101 3BHE025541R0101 prove their worth. This module is not simply a circuit board inside a cabinet; it is a core enabler of stable automation in environments where errors can cascade into costly disruptions.

Typical users of this hardware include operators in oil refineries, paper mills, water treatment facilities, and high-availability manufacturing plants. In these environments, systems must constantly coordinate sensors, actuators, and process controllers. The ABB PCD231B101 3BHE025541R0101 is engineered to handle exactly this type of integration, supporting continuous monitoring and control under harsh industrial conditions.

Engineers and system integrators choose it because it reduces the gap between field devices and the distributed control system. Whether the task is ensuring precise flow regulation in pipelines, maintaining temperature stability in a glass furnace, or managing distributed loads in a turbine hall, this unit supports dependable operation. By providing compatibility within ABB’s proven DCS platforms, it gives operators confidence that their automation backbone will run smoothly, even when the plant is under stress.

In short, the ABB PCD231B101 3BHE025541R0101 finds its place in real-world scenarios where reliability, consistency, and lifecycle stability outweigh everything else.

ABB PCD231B101 3HE025541R0101

Product Introduction & Positioning

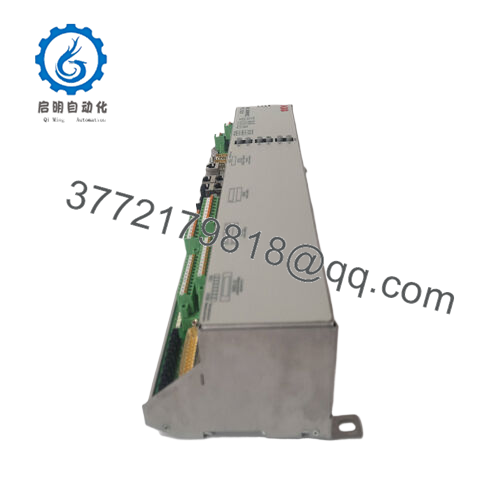

The ABB PCD231B101 3BHE025541R0101 is a control module designed as part of ABB’s distributed control system architecture. Within a plant automation network, its role is to serve as an intelligent link between process-level data and higher-level decision logic. In practice, that means it accepts input signals, processes information in real time, and transmits output instructions that keep industrial processes within tight tolerances.

This module is built for seamless compatibility with ABB’s advanced DCS families, allowing engineers to scale their control environment without introducing integration headaches. Positioned as a mid-level module within ABB’s portfolio, it balances processing capability with rugged physical design, making it suitable for both retrofit projects and greenfield installations.

From a system perspective, the ABB PCD231B101 3BHE025541R0101 sits in the I/O and communication layer of automation architecture. It provides the reliability of ABB’s hardware ecosystem, while also supporting long-term maintainability through firmware updates and diagnostic access. This positioning makes it a valuable investment for operators who need proven performance without constant hardware replacements.

Engineers appreciate it because it reduces commissioning complexity and slots into existing ABB environments without special adapters or workarounds. That saves both project time and ongoing maintenance resources.

Key Technical Features & Functional Benefits

One of the most important features of the ABB PCD231B101 3BHE025541R0101 is its ability to maintain stable operation in demanding environments. Its processing performance ensures low latency between sensor inputs and actuator responses, which is crucial for applications like high-speed manufacturing or sensitive batch processes. This rapid response capability reduces error margins and helps operators maintain strict process compliance.

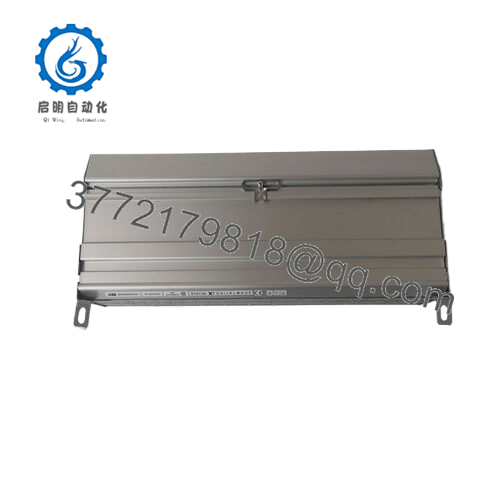

From a hardware standpoint, the module is designed with industrial-grade components that can withstand temperature fluctuations, electrical noise, and mechanical vibration. Its compact footprint allows it to fit neatly within standard control cabinets, and its connector layout simplifies wiring during installation. These design details matter for integrators who need to minimize downtime when bringing new equipment online.

Compatibility is another strong advantage. The ABB PCD231B101 3BHE025541R0101 communicates smoothly within ABB’s DCS frameworks and aligns with common industrial communication standards. This means it can function as part of a larger system without requiring customized middleware or extensive reconfiguration.

Finally, long-term reliability is embedded in its design. Efficient thermal management prevents overheating, while ABB’s build quality ensures the unit operates consistently across its service life. Maintenance teams benefit from built-in diagnostic capabilities, which allow early detection of issues before they escalate. Together, these attributes deliver peace of mind in facilities where unplanned downtime is not an option.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | PCD231B101 3BHE025541R0101 |

| Brand | ABB |

| Type | Control Module |

| Power Supply | 24 V DC (nominal) |

| Operating Temperature | –20 °C to +55 °C |

| Mounting | DIN-rail / cabinet-mounted |

| Dimensions | 130 mm x 45 mm x 180 mm (approx.) |

| Weight | 0.9 kg |

| Interfaces | Digital/analog I/O, system bus |

| Certifications | CE, UL, industrial safety compliant |

| Cooling | Passive convection |

| Environmental Rating | IP20 for cabinet-protected use |

Related Modules or Compatible Units

-

ABB PCD230A101 3BHE022291R0101 – Companion module from the same family, optimized for complementary control functions.

-

ABB PCD232A 3BHE022293R0101 – Extended variant offering additional I/O handling capacity.

-

ABB PFEA111-20 3BSE028140R0020 – Interface module supporting broader connectivity in ABB DCS setups.

-

ABB REF615 HBFFAEAGNBA1ANB1XD – Protection relay that integrates with the same automation architecture for power applications.

-

ABB DSAO120AK01 3BSE020419 – Analog output board that often works in conjunction with the PCD231B101 in process loops.

-

ABB DSPC174 3BSE005461R1 – Processor module providing higher computational power for extended control tasks.

-

ABB CI522AK04 – Communication unit used for network integration alongside process modules.

Installation Notes & Maintenance Best Practices

When planning to install the ABB PCD231B101 3BHE025541R0101, engineers should first confirm cabinet space and proper ventilation. Adequate clearance should be maintained on all sides to ensure heat dissipation, and grounding must follow ABB’s recommended guidelines to avoid electrical noise interference. Cable routing is also critical, as power and signal lines should be separated to prevent cross-talk.

For long-term use, ABB advises scheduled visual inspections of connectors and housing to detect early signs of wear. Maintenance teams should run diagnostic routines at regular intervals, verifying that input and output signals remain within calibration limits. Firmware updates, when available, should be applied to maintain system security and optimize performance. By following these practices, operators extend the lifespan of the ABB PCD231B101 3BHE025541R0101 and reduce the likelihood of costly unexpected downtime.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626