Description

Real-World Use & Application Scenarios

Effective regulation of generator excitation is fundamental for power plants and industrial energy systems to maintain stable voltage output, regulate reactive power, and ensure grid reliability. The ABB PCD231B101 programmable controller operates at the heart of excitation control systems, where it precisely manages the excitation transformer’s outputs to stabilize generator performance. This product is extensively used in power generation facilities, including thermal, hydroelectric, and renewable plants, where control accuracy directly impacts operational safety and energy quality.

In industrial automation contexts, the ABB PCD231B101 supports automated voltage regulation by adjusting excitation current according to grid or load demands. The device’s dual digital controller architecture allows independent management of dual excitation transformers, boosting system redundancy and operational reliability. Its role is vital in addressing challenges such as voltage fluctuations, transient disturbances, and reactive load compensation in modern, complex power infrastructures.

Product Introduction & Positioning

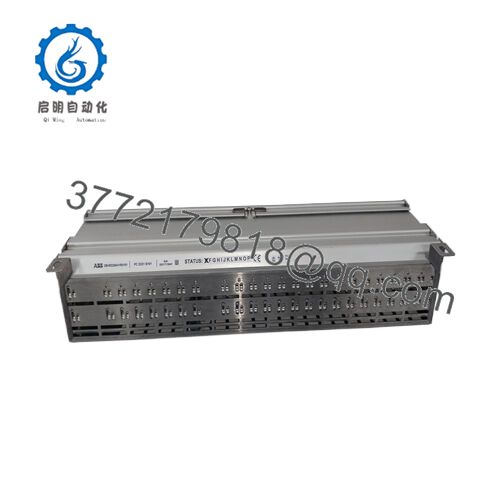

The ABB PCD231B101 is a high-performance excitation unit controller designed for managing the excitation system of synchronous generators. It features dual independent digital controllers integrated into one module, each capable of controlling an excitation transformer. The product fits within ABB’s advanced power automation systems, particularly supporting AC 800M and related DCS platforms.

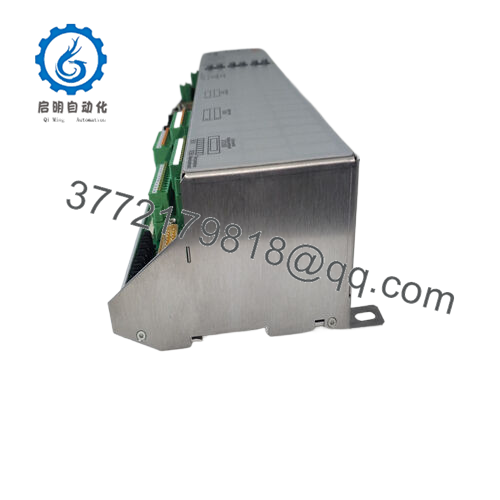

This controller offers robust digital signal processing, enabling precise control of excitation currents that directly influence generator voltage output quality. By delivering multi-channel control capabilities and advanced diagnostics, the ABB PCD231B101 equips engineers with reliable tools for maintaining grid stability and optimizing power plant responses to load variations. Its modular format ensures seamless integration into distributed control infrastructures, facilitating upgrade and expansion projects.

PCD231B101

PCD231B101

Key Technical Features & Functional Benefits

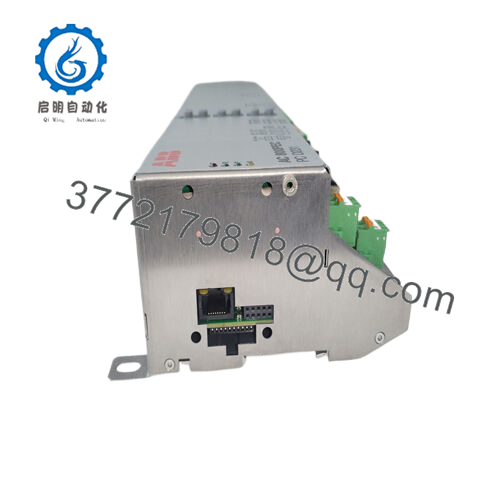

The ABB PCD231B101 is powered by a 32-bit RISC processor providing responsive control and high computational efficiency. Its dual-controller design supports simultaneous management of two excitation transformers, enhancing fault tolerance and enabling parallel or fallback control strategies. The module supports communication via multiple industrial protocols, including Modbus RTU and Profibus DP, allowing easy integration into complex networked control systems.

Designed for precision, it regulates excitation current with rapid response times, minimizing voltage deviations and reducing power quality disturbances. The unit’s diagnostic capabilities include real-time monitoring of operational parameters and fault detection, simplifying system maintenance and troubleshooting. Physically compact and lightweight (approximately 3 kg), it is engineered for easy installation within standard control racks while withstanding industrial environmental conditions.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | PCD231B101 |

| Brand | ABB |

| Product Type | Excitation Unit Controller |

| Processor | 32-bit RISC CPU |

| Memory | 16 MB RAM, 16 MB Flash |

| Communication Ports | 2x RS232/485, 1x Ethernet |

| Dual Controller | Yes, independent control loops |

| Supported Protocols | Modbus RTU, Profibus DP |

| I/O Capacity | Supports extensive I/O configurations |

| Operating Temperature | -20°C to +70°C |

| Weight | Approx. 3 kg |

| Dimensions | Standard rack mount size |

Related Modules or Compatible Units

ABB CI871 – Digital I/O module frequently paired with PCD231B101 units for expanded control.

ABB AC 800M Controller – Core distributed control system that supports the PCD231B101 excitation controller.

ABB PM867 – Redundant power and processor modules designed for critical system reliability.

ABB DSQC669D – Digital signal and controller used alongside excitation control units in power automation.

ABB CI810 – Communication interface facilitating networked control for modules like PCD231B101.

ABB DSP 250 – Power supply units compatible with control modules in the same excitation system architecture.

Installation Notes & Maintenance Best Practices

Installation of the ABB PCD231B101 requires ensuring stable 24 V DC power supply with sufficient capacity for continuous operation. Proper grounding and shielding for communication and control cables are essential to prevent interference that may impact signal clarity and system stability. The controller should be mounted within standard control racks with adequate ventilation to maintain a temperature range of -20°C to +70°C.

Regular maintenance involves inspection of cable connections, monitoring of diagnostic LEDs, and validation of communication link integrity. Periodic software updates and configuration backups should be performed to ensure optimal functionality. Keeping spare controllers on hand and configuring automatic fault alerts contributes to minimizing downtime in safety-critical power generation environments.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626