Description

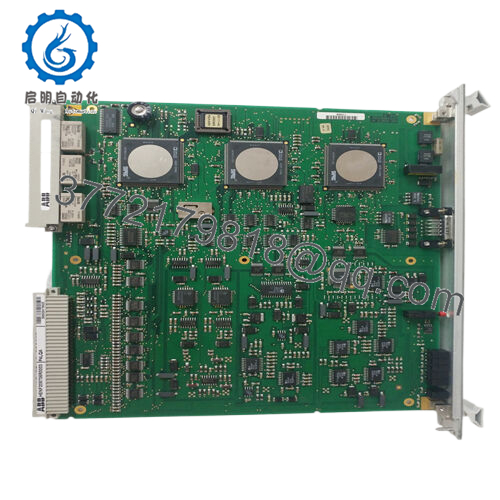

ABB P4LQA HENF209736R0003 is a high-precision process control and measurement equipment designed for seamless integration into industrial automation systems. It can interface with various sensors and actuators, serving as a central node for data collection and control signal distribution. This device supports multiple communication protocols, including Profibus PA and HART, and can effectively communicate with other components in the automation architecture, from field instruments to advanced control systems.

ABB P4LQA HENF209736R0003

This device is equipped with advanced signal processing capabilities, which can accurately measure and process various process variables such as pressure, flow rate, liquid level, and temperature. It can convert raw sensor signals into reliable and standardized output signals, making it easy for control systems to interpret. The device also has built-in diagnostic functions, which can continuously monitor its own status and the integrity of connected sensors. Once there is an abnormal situation such as sensor failure or signal deviation, it can promptly issue an alarm to the operator to quickly troubleshoot and reduce downtime.

ABB P4LQA HENF209736R0003

Technical specifications:

Model P4LQA HENF209736R0003

Brand ABB

Type Process Control and Measurement Equipment

Input signal type: pressure, flow rate, liquid level, temperature (depending on the connected sensor)

Output signal 4-20 mA, digital signal (Profibus PA, HART)

Working temperature range -40 ° C to 85 ° C

Installation method: DIN rail installation or panel installation

Size 110 x 90 x 60 mm

Weight 0.5 kg

Interface/Bus Profibus PA, HART

Certification CE, RoHS

Supports protocols Profibus PA and HART

Typical power consumption 10 W

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818

Main features and advantages:

Its high-precision measurement capability ensures precise process control, reduces error ranges in critical operations, and improves product quality. By minimizing the changes in process variables, it helps various industries meet strict quality standards and regulatory requirements, avoiding high rework and product recall costs.

The multi protocol support of this device simplifies system integration and can easily integrate into existing automation architectures without the need for large-scale modifications. This reduces the time and cost required for system upgrades and expansions. The built-in diagnostic function not only enables rapid fault detection, but also supports predictive maintenance, which helps prevent unexpected failures and reduce long-term maintenance costs.

The robust design of ABBP4LQA HENF209736R0003 ensures reliable operation in harsh industrial environments, capable of withstanding extreme temperatures, vibrations, and electromagnetic interference. Its ability to flexibly execute various control functions and adapt to different process requirements makes it a universal solution for multiple applications, providing high return on investment by improving productivity and operational stability.

Application areas:

In the chemical industry, it is used to precisely control the flow and pressure of chemical fluids in reactors and pipelines, ensuring the consistency of chemical reactions and product quality. By accurately measuring and adjusting process variables, it helps prevent dangerous situations from occurring and optimize production efficiency.

In power plants, this equipment plays a crucial role in monitoring and controlling parameters such as steam pressure, boiler water level, and fuel flow rate. This enables operators to optimize the power generation process, improve the efficiency of turbines, and ensure the safe and reliable operation of the power plant.

In the water treatment industry, ABB P4LQA HENF209736R0003is used to measure and control the water level in storage tanks, the flow rate of treated water, and the pressure in distribution systems. It helps to maintain the quality of treated water, ensure stable water supply to consumers, and reduce water waste. Whether operating in industries with high precision requirements or in challenging environmental conditions, this product can provide consistent and reliable performance.

Related products:

ABB P4LQB HENF209737R0003: Faster processing speed and increased input channels, suitable for more complex process control applications that require simultaneous processing of multiple variables.

ABB P4LQA HENF209735R003: With basic measurement and control functions, it provides an affordable solution for small projects or tasks with low process control requirements.

ABB P4LQC HENF209738R0003: Equipped with advanced self calibration function, reducing the need for manual calibration and ensuring long-term measurement accuracy, it is very suitable for applications that require extremely high long-term accuracy.

ABB P4LQD HENF209739R0003: With higher communication bandwidth, it can achieve faster data transmission and real-time control in high-speed process automation systems.

ABB P4LQE HENF209740R0003: With better compatibility with emerging industrial IoT platforms, it facilitates seamless integration into smart factory ecosystems, enabling enhanced data analysis and remote monitoring.

ABB P4LQF HENF209741R0003: Built in safety features provide an additional layer of protection in hazardous industrial environments where safety is paramount.

Installation and maintenance:

Before installing ABB P4LQA HENF209736R0003, it is necessary to carefully select and calibrate appropriate sensors based on the specific process variables to be measured. Ensure that the communication protocol of the device matches the protocol of the existing control system and other connected devices. Verify whether the input voltage supply is within the specified range and whether the power supply is stable to avoid any electrical interference that may affect measurement accuracy.

For continuous maintenance, the status indicator lights on the equipment should be checked regularly to monitor its operating status. Regularly check communication cables and connectors for signs of wear, damage, or loose connections, as these issues may interfere with data transmission. It is also recommended to conduct regular calibration checks on the connected sensors and devices themselves to ensure continuous measurement accuracy. Update the firmware of the equipment according to ABB’s release plan to benefit from the latest features, performance improvements, and security enhancements.

Other ABB product models:

ABB 206-00212

ABB 216AB61 HESG324013R101

ABB 216AB61 HESG324013R0101

ABB 216DB61 HESG324063R100/H

ABB 216DB61 HESG324063R100/H

ABB 216DB61 HESG324063R0100

ABB 216EA61B HESG448230R1/G

ABB 216EA62

ABB 216EA62

ABB 216EA62

ABB 216EA62 1MRB150083R1/F

ABB 216MB66 HESG324510M1

ABB 216NG62A HESG441634R1/K HESG216876

ABB 216NG63A HESG441635R1 HESG216879/K

ABB 216V62a HESG324442R13/B

ABB 216VC62a HESG324442R112/F

ABB 216VC62a HESG324442R112/F

ABB 216VC62a HESG324442R112/F

ABB 216VC62a HESG324442R13/B

ABB 216VC62A HESG324442R112/F

ABB 216VC62A HESG324442R13

ABB 216VC62A HESG324442R13

ABB 216VC62A HESG324442R13

ABB 216VC62a/P1000 HESG324442R112

ABB 2CSG299893R4052

ABB 2CSG299893R4052

ABB 2UBA00004416R0007

ABB 3AUA0000036521

ABB 3AUA0000110430

ABB 3BDS005799R1 PM665

ABB 3BHB003688R0101

ABB 3BHB003688R0101

ABB 3BHB003689

ABB 3BHB003689

ABB 3BHB003689

ABB 3BHB003689 3BHB003688R0101

ABB 3BHB005243R0105

ABB 3BHB005243R0106 KUC755AE106

ABB 3BHB005243R0117

ABB 3BHB005245R0101

ABB 3BHB005922R0001

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626