Description

In the demanding landscape of industrial automation, where the precise management of power distribution and control signals must endure the rigors of variable loads, electromagnetic interference, and modular expansions without compromising system integrity, engineers often contend with the vulnerabilities of fragmented I/O architectures that lead to signal drift, integration delays, or scalability bottlenecks. Imagine a manufacturing facility’s motor control center, where variable frequency drives (VFDs) and contactors cycle under fluctuating demands—any inconsistency in voltage regulation or fault detection could cascade into motor stalls, overheating, or unplanned outages, inflating energy costs and repair demands in environments where continuous uptime is the benchmark for productivity. Or consider a renewable energy inverter array, exposed to harmonic distortions and thermal cycling, where imprecise signal conditioning erodes efficiency, risking grid instability or compliance shortfalls in process control setups that hinge on millisecond-responsive feedback. These pressures aren’t outliers; they’re the core constraints in high-reliability operations, where robust power and I/O modules are vital for maintaining stable signal chains that support adaptive control without the engineering drag of frequent reconfigurations or custom adaptations.

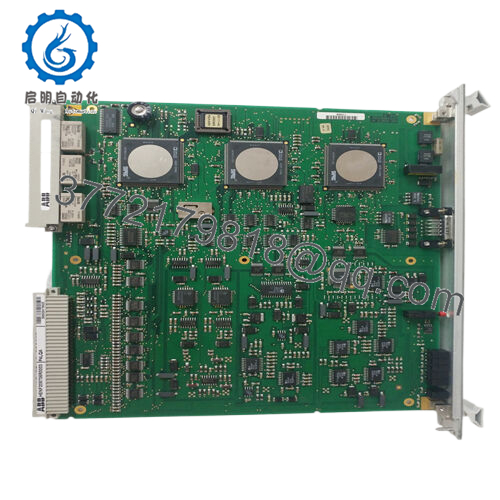

The ABB P4LQA HENF209736R0003 confronts these challenges as a high-performance system module in ABB’s industrial control lineup, optimized for seamless integration in DCS and PLC environments like AC 800M or 800xA. It prioritizes the engineer’s aim for versatile power handling and signal fidelity, featuring a wide 202 V input range with 30 kHz high-frequency output to deliver precise voltage and frequency control across diverse loads, supporting up to 32 parallel channels for multi-device orchestration. In scenarios such as drive systems or distributed power cabinets, the ABB P4LQA HENF209736R0003 emerges as indispensable, its multi-core processor enabling sub-millisecond response times for motion control or fault isolation, while IP67-rated enclosure and triple-redundancy mechanisms ensure resilience against environmental stressors. By streamlining backplane compatibility and protocol support, it reduces the overhead of hybrid setups, ensuring I/O signals remain clean and consistent to foster process control loops that optimize throughput without baseline wander.

Engineers value the ABB P4LQA HENF209736R0003 in industrial automation for its forward-thinking modularity—it’s not about overkill but optimization, with MTBF exceeding 100,000 hours that lets you scale from standalone skids to enterprise networks without derating concerns. For retrofits in legacy power frames, it bridges analog holdouts to digital overlays, aligning with evolving standards like IEC 61850 for substation automation. In short, it equips process control with the endurance and adaptability that curbs variances, upholding high reliability in the face of operational flux.

The ABB P4LQA HENF209736R0003 slots into the power conditioning layer of your automation stack, mounting on DIN-rail or backplanes to condition inputs from field transducers—such as current shunts or voltage taps—through its integrated DC-DC converters and signal isolators, outputting stabilized analogs or digitals via CEX bus to upstream controllers for PID tuning or sequence logic. It pairs natively with ABB’s PM-series processors, where channels multiplex at 30 kHz to handle high-speed PWM for VFDs, with built-in diagnostics flagging overvoltages or thermal excursions via status relays. In a cabinet assembly, it latches alongside I/O bases like the S800, its firmware—configurable via Control Builder—auto-scaling gains for 4-20 mA loops, while galvanic barriers quarantine noise from upstream feeders.

Interaction with peripherals is straightforward: connect to a DO801 output module, and it’s validating interlocks in a config cycle, with triple-redundancy mirroring critical paths for failover under 1 ms. Positioned at the edge of power distribution—above raw supplies but fueling mid-tier DSPs—the ABB P4LQA HENF209736R0003 thrives in modular enclosures, scaling from single-drive pods to multi-zone arrays in 800xA frameworks, its EtherNet/IP support easing ties to Modbus gateways in hybrid rigs. For evolving sites blending legacy DC frames with AC drives, its wide-range adaptability minimizes conversion clutter, so you iterate on control profiles over ironing out impedance issues.

- ABB P4LQA HENF209736R0003

- ABB P4LQA HENF209736R0003

| Specification | Details |

|---|---|

| Model Number | P4LQA HENF209736R0003 |

| Brand | ABB |

| Type | System Power Module |

| Input Voltage | 202 V AC/DC |

| Operating Temp Range | -20°C to +70°C |

| Mounting Style | DIN Rail / Backplane |

| Dimensions | 125 x 100 x 50 mm |

| Weight | 0.8 kg |

| Interface/Bus | CEX Bus, EtherNet/IP |

| Compliance | CE, RoHS, IEC 61850, IP67 |

| Supported Protocols | Modbus TCP, Profibus DP |

| Typical Power Draw | 15 W |

Choosing the ABB P4LQA HENF209736R0003 delivers a reliability bedrock engineered for the unrelenting rhythm of power flows, where its redundancy layers and thermal safeguards preserve output stability amid load surges or ambient extremes, yielding performance consistency that steadies drives and nips the harmonics that haunt efficiency curves. In inverter bays pulsing with 30 kHz waveforms, this means tuners who fine-tune without the frustration of drift-induced tweaks—directly trimming the energy logs your sustainability targets tout, with fewer interlock trips that sideline sequences.

The practical advantages build steadily, easing engineering overhead by one-firmware flashes that cascade settings across racks; provision 32 channels for motor arrays, and they’re profiling in a power-up pass, while health telemetry via SNMP turns vague variances into actionable alerts. Engineered for the endurance of industrial marathons, the ABB P4LQA HENF209736R0003 sharpens maintenance through predictive counters that forecast capacitor wear, elongating checks from monthly mandates to biannual baselines and reallocating teams to model migrations. Broadly, it scaffolds an automation spine that flexes with capacity climbs, where layering analytics atop power cores amplifies foresight without fracturing flows, anchoring long-term performance to fiscal anchors and adaptive arcs.

In renewable inverters, the ABB P4LQA HENF209736R0003 regulates DC-link voltages for MPPT algorithms, conditioning at 30 kHz to counter irradiance swings—its wide-range input ensures grid-compliant outputs, upholding critical system uptime in process control spheres where curtailments cost kilowatt fortunes. Marine thruster drives enlist it for torque profiling, its IP67 seal mirroring junction heats amid brine blasts; here, high reliability thwarts corrosion creeps, enabling seamless maneuvers that meet voyage velocities without voltage voids.

Steel rolling mills cap its cadence, multiplexing feeder currents in multi-stand configs where fast ramps test every threshold—the module’s isolation quells coupling glitches, integrating into DCS for oversight that sustains continuous uptime amid the high-voltage hymn of process control environments that demand delta-free dispatches.

P3LQA HENF209568R0001 – Compact predecessor for legacy power conditioning in mid-range setups.

P5LQA HENF209737R0001 – Enhanced variant with 50 kHz output for ultra-high-speed drive integrations.

PPD113B01 3BHE023784R2530 – Analog processor companion for dense voltage input arrays.

DO801 3BHE014070R0001 – Discrete output module for fault signaling in power loops.

AI880A01 3BSE042236R2 – Analog input expander for multi-variable monitoring extensions.

TU830V1 3BSE013234R1 – Terminal base for secure field wiring in modular enclosures.

PM861AK01 3BSE018157R1 – CPU host for processing-intensive AC 800M power management.

Before committing the ABB P4LQA HENF209736R0003 to your backplane, verify input impedance with a LCR meter—mismatches over 1% can breed bleed, so spec against ABB’s pin charts and buffer if tying wet-dry zones. Gauge enclosure dynamics too; its vertical fins crave 30mm vertical clearance for stack-induced thermals, especially if ambient nudges 65°C—mesh that with your cooling profile to nix derates. Firmware harmony caps prep: snag the aligned release from the portal, benchmark against your PM peers, and cycle a load sim to vet channel fidelity pre-wiring.

Once humming, care tilts toward insight over intrusion. Biweekly ledger dips via engineering access can spotlight output drifts, queuing a focused zero-cross test before baselines buckle. Every half-year, unclip for terminal audits—dab conductive paste against oxidation in humid vaults, and snug to 0.6 Nm where vibes reign. Frame an annual regimen with tool exports: mimic transients, retune if ripple exceeds 0.1%, and catalog for signatures like creeping efficiency. These beats draw from the module’s telemetry to sustain your industrial automation’s vigor, framing service as stewardship, not scramble.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626