Description

Real-World Use & Application Scenarios

The ABB OCAH 940181103 finds its place in demanding industrial automation settings such as power distribution, manufacturing, and process control plants. This module is designed primarily for logic control and signal conditioning within distributed control systems, making it highly favored in environments where precise automation and reliable output signal management are imperative. Its application extends to utilities and heavy industry, where complex control sequences and output signal integrity determine operational success and safety.

Used in industrial automation configurations, the ABB OCAH 940181103 supports control systems that require rugged reliability under continuous operational stress. It is particularly suited for installations involving output control panels where stable, repeatable signal generation is crucial for downstream equipment like actuators, valves, and field devices. Engineers value this unit for its ability to handle intricate automation scenarios that include real-time data processing, output logic execution, and communications with supervisory systems via common industrial protocols.

Applicable in control systems requiring high performance and durability, the ABB OCAH 940181103 stands out for its consistent operation under varying environmental conditions. Its capability to maintain signal accuracy and control integrity underpins advanced manufacturing and energy generation processes, where downtime and errors carry significant cost and safety implications.

Product Introduction & Positioning

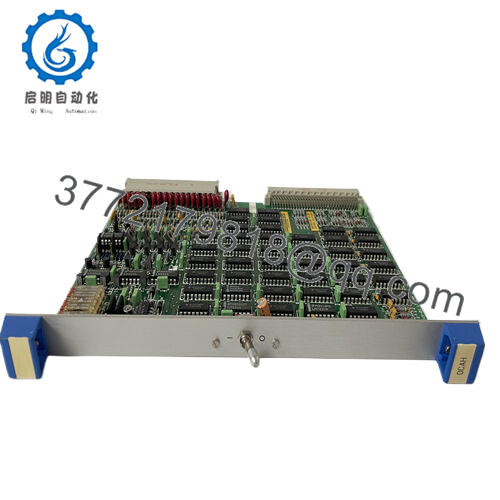

The ABB OCAH 940181103 is an advanced programmable control module engineered as part of ABB’s broader automation platform. It acts as a programmable logic controller (PLC) unit specialized in output signal management within distributed control systems (DCS). Designed for use in control racks, it executes predefined automation routines that convert control logic into actionable signals for machinery and electrical equipment.

- OCAH 940181103

Within the ABB automation architectures, the ABB OCAH 940181103 integrates seamlessly as a satellite output module. It processes input commands and generates corresponding output signals that drive equipment status changes or alarms, forming a critical interface between automation software and physical devices. This module’s programmable nature allows customization tailored to diverse industrial processes, facilitating fine-tuned control sequences.

System integrators appreciate the module’s compatibility with industrial communication standards such as PROFINET and Modbus RTU, which simplifies linking with higher-level supervisory controls. Its reliability and precision help ensure overall system responsiveness and reduce operational risk, marking it as a trusted component for engineers designing scalable and maintainable control systems.

Key Technical Features & Functional Benefits

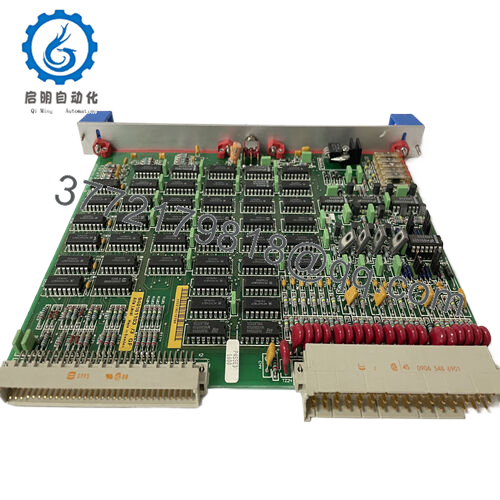

The ABB OCAH 940181103 delivers high efficiency with low power consumption, tailored for use in complex automation frameworks. It provides consistent output signal conditioning with low latency, supporting up to tens of channels of signal output control depending on system configuration. Its programmable logic capacity enables it to handle custom control algorithms and sequential output tasks effectively.

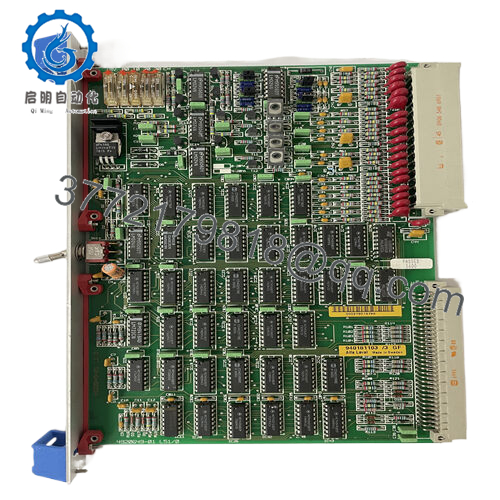

Built for industrial robustness, the module features an IP65-rated enclosure that protects against dust and water ingress, enabling it to withstand harsh factory environments and elevated temperatures with operational stability from -25°C up to +70°C. This durability reduces maintenance needs and extends lifetime, making it suitable for long-term deployments.

The module supports versatile communication with supervisory systems through PROFINET and Modbus RTU protocols, facilitating seamless integration with ABB’s DCS and third-party automation systems. Real-time feedback and diagnostics are empowered by these interfaces, allowing operators to monitor and optimize performance continuously.

Thanks to advanced manufacturing techniques, the ABB OCAH 940181103 exhibits excellent signal fidelity with minimal electromagnetic interference susceptibility. It provides dependable control signals crucial for maintaining process accuracy and safety in automated environments.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | OCAH 940181103 |

| Brand | ABB |

| Product Type | Programmable Control Module (PLC) |

| Input Voltage | 220 V AC ±10% |

| Output Frequency | 30 kHz ±0.5% |

| Operating Temperature | -25 to +70 °C |

| Enclosure Protection | IP65 Rated |

| Communication Protocols | PROFINET, Modbus RTU |

| Dimensions (W x H x D) | 152 x 51 x 203 mm |

| Weight | Approx. 3 kg |

| Certifications | CE, IEC, UL |

Related Modules or Compatible Units

OCAH 940181104 – Complementary output control module offering extended channel capacity.

BMS611B06 – Circuit protection module ensuring electrical safety in the automation setup.

216BM61B – Advanced process control module commonly integrated within the same control racks.

PCD235B1101 – Excitation control unit, often coordinated with output modules for power plant applications.

REG216 – Numerical protection relay frequently paired for generator and power system safety.

230SM – Modular control system compatible with multiple ABB control modules for scalable automation solutions.

Installation Notes & Maintenance Best Practices

When installing the ABB OCAH 940181103, ensure sufficient cabinet space to maintain natural convection cooling. Proper grounding and shielding are essential to protect the module from electromagnetic interference, which could compromise signal integrity. Clearance for easy wiring access and future servicing should be planned during installation design, along with adherence to electrical standards for safety.

Periodic maintenance should focus on visual inspections for cleanliness and secure connections, with particular attention to terminals and communication interfaces. Regular functional diagnostics via the PROFINET or Modbus interface help preempt failures through early detection of anomalies. Keeping firmware updated according to ABB releases is critical to optimizing module performance and system security over its operational life.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626