Description

In the labyrinth of industrial automation, where drive systems orchestrate the symphony of motors across vast factory floors or processing lines, the specter of communication silos can fracture synchronization—imagine a conveyor cascade in a logistics hub where desynchronized inverters lead to jammed pallets and halted throughput, or a paper mill where mismatched speed commands ripple into web tears and waste cascades, inflating scrap rates and safety exposures in environments where every millisecond of coordination counts. These fractures deepen in multi-axis setups, where fiber optic chains must branch reliably without signal attenuation or insertion losses that erode command fidelity, turning robust controls into brittle afterthoughts. This is the crux the ABB NDBU-95 64008366 confronts as a star connection branching unit, honed for DDCS fiber networks in ACS and DCS800 drive ecosystems, ensuring seamless signal distribution that binds your drives into a cohesive, responsive fabric for unyielding process control.

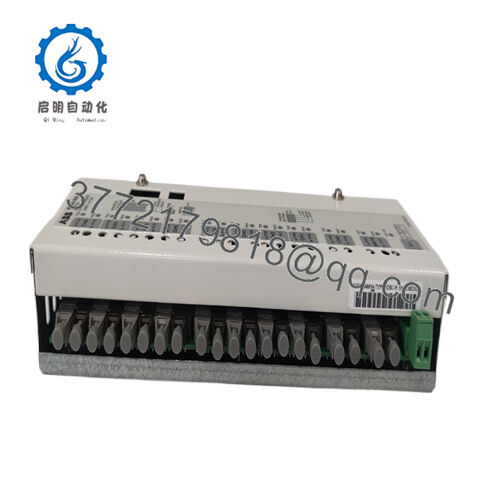

NDBU-95 64008366

Commissioning teams scaling variable frequency drives (VFDs) in decentralized architectures often grapple with units that introduce optical crosstalk or demand custom splitters, complicating rack layouts and undermining high reliability amid electromagnetic barrages from adjacent power runs. The ABB NDBU-95 64008366 emerges as indispensable here, splitting one input into nine parallel 10 Mb channels via plastic fiber, optimized for real-time data flows in applications like coordinated crane hoists or extrusion lines where torque sharing demands instantaneous feedback. It’s a bulwark in sectors such as mining or automotive assembly, where industrial automation thrives on fault-tolerant comms to avert the domino of desynced axes that could cascade into mechanical binds or production voids. Without this branching prowess, you’d resort to daisy-chain daunts or proprietary extenders, funneling resources from loop optimization to optical patchwork in the press of expansion deadlines.

As facilities evolve toward fiber-enriched IIoT overlays, the hunger swells for passive splitters that embed loss budgeting without active power draws. The ABB NDBU-95 64008366 prevails with its 1/9 configuration, clad in rugged coating for vibration-laced bays while preserving signal integrity across 50/125 μm cores—reframing isolated drives into networked cohorts. This unit isn’t mere cabling; it’s the arbor that fans control pulses into unified action, arming your engineers to harvest sync metrics for predictive tweaks rather than tracing dropouts in event logs. In conformance arenas like food processing or renewables, where drive harmony ties to throughput quotas, it steels optical reliability that ladders to scalable, low-latency automation.

| Specification | Details |

|---|---|

| Model Number | 64008366 |

| Brand | ABB |

| Type | Optical Branching Unit |

| Input Voltage | N/A (Passive) |

| Operating Temp Range | -40°C to +85°C |

| Mounting Style | Panel / DIN Rail |

| Dimensions | 100 x 50 x 20 mm |

| Weight | 0.25 kg |

| Interface/Bus | Plastic Fiber (DDCS) |

| Compliance | CE, RoHS |

| Supported Protocols | 10 Mb Fiber Optic |

| Typical Power Draw | 0 W |

The ABB NDBU-95 64008366 perches at the distribution nexus of your drive comms stack, passively forking a single DDCS fiber input into nine output legs to fan commands from a master controller—like the CI520 module—to slave inverters in an ACS800 array, embedding it as the silent multiplier in enclosure hubs where it mates via ST connectors to sustain 10 Mb throughput without regeneration. This vantage trims cable sprawl in star topologies, where it slots alongside termination blocks for clean routing, channeling torque setpoints or status polls downstream while upstream it echoes link health via reflected light budgets—envision it as the unobtrusive prism in a light lattice, refracting pulses to synchronize motor phases without fidelity fades.

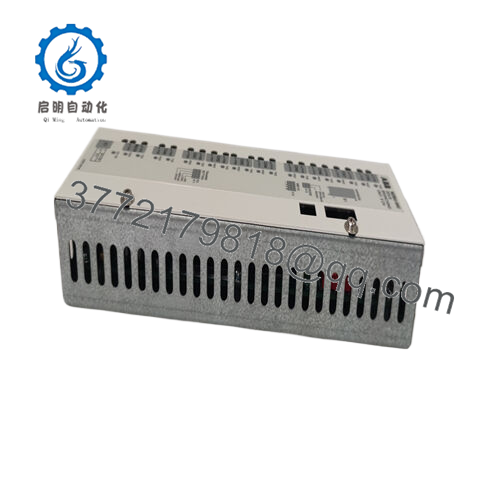

Its interplay in live arrays is whisper-quiet yet resolute: equal split ratios hold attenuation under 20 dB per leg, with polymer cladding that shrugs off bends down to 30 mm radii, piping unerring data to field units for closed-loop velocity matching. Encase it in IP54 mounts for oily atmospheres, and optional coatings buffer against chemical drifts, while diagnostics lean on master-side OTDRs to map losses, spotlighting dust caps or connector grime sans disassembly. In redundant webs, it mirrors paths for failover loops, upholding sync amid hot splices. Upstream, it draws from PROFIBUS gateways for HMI syndication; downstream, it arms VFD feedback chains, all field-routable with no tools beyond a fiber cleaner. For growth, the ABB NDBU-95 64008366 cascades via output daisy-chains, plug-scalable to swell node counts without core rewires, evolving your fiber fabric toward resilient, edge-synced process control that outpaces discrepancies.

Adopting the ABB NDBU-95 64008366 endows your drive ensembles with optical oneness that dissolves the drag of siloed signaling, crucial in multi-motor rigs where phase lags could otherwise spawn vibrations and bearing gnaws. In the whirl of ramped operations, this forges tempo fidelity that endures—servos align sans slip, burnishing cycle times in winding lines and foreclosing the collateral from torque imbalances that dog uneven splitters. The passive core, to boot, evades the auxiliary feeds that burden active hubs, letting your layout leads chase modularity over mitigation gear, which compresses panel proofs and shields from the tally of comms flakes in humid vaults.

This unit’s fiber heritage tilts to the fray of factory fortitude, with bend tolerance that clings to efficacy through cable tugs, lightening the retrofit reins in serpentine routings and locking performance steadiness amid throughput surges. Operators glean from its loss profile to preempt dimouts, habitually spotting polish pits ere they strand spans, which hastens heals and elongates link lifespans in the swap. Built for the boundless beat of axis duty, it meshes with uptime oaths, its zero draw easing green audits in battery-tethered bays. And its connector congruence curtails splice sagas, snapping to extant ST ports sans adapters, so your net expansions ebb even-keeled.

Beyond, the ABB NDBU-95 64008366 fosters forking flexibility: output taps graft to wavelength muxes for hybrid loads, stewarding stake as DDCS grids layer Ethernet veneers. This suppleness slims proof burdens, with pulse echoes ratifying IEC optics norms sans extras. At root, it’s a radix for radiant relay, where deft division distills discords from drive to dynamo, alchemizing branch blinders into banded boons.

In material handling depots, the ABB NDBU-95 64008366 fans fiber to nine hoist inverters along gantry spans, splitting 10 Mb pulses amid dusty drafts and load swings, where its equal splits and coating tenacity secure critical system uptime in process control environments riven by sync strains—high reliability holds in averting sway-induced stalls without pallet piles. Continuous uptime bolsters sort rates sans snarls.

Metal rolling mills marshal the ABB NDBU-95 64008366 to sync strip tension drives in tandem stands, braving mill scale and thermal gusts with plastic fiber poise that counters EMI veils, pivotal for process control where datum dispatch dictates gauge holds, upholding high reliability amid alloy fluxes.

Renewable tracking arrays array the ABB NDBU-95 64008366 to branch commands to azimuth motors in solar farms, weathering wind whips with low-loss legs for fast data cycles that sustain panel tilts—integral to process control environments demanding unswerving harmony amid solar sways.

NDBU-91 64008362 – 1/5 split variant for lighter branching in compact ACS clusters.

NDBU-96 64008367 – 1/13 configuration for denser node distributions in large-scale DCS.

CI520 3BSE012211R1 – Master comm module for PROFIBUS integration with DDCS fiber.

NDBS-01 3HNA006147-001 – Straight-through coupler for linear extensions in fiber chains.

NDBU-95C Variant 64008382 – Coated upgrade for corrosive bays with enhanced abrasion resistance.

DDCS XL Adapter 3BSE008510R1 – Bus interface for tying legacy drives to modern branching.

NDBU-92 64008363 – 1/7 mid-range splitter for balanced multi-axis torque sharing.

Before threading the ABB NDBU-95 64008366 into your fiber loom, tally leg counts against master maps—overforks fog addressing; ABB’s optic sims sketch this sans snags. Assay insertion loss with a light meter on test stubs to peg under 21 dB totals, and berth it in slack-free mounts with 50 mm loops for thermal flex, as coiled heat can kink polymers—vent with mesh if enclosures bake. Polish ST ferrules to UPP specs for index match, and pulse a loopback to chart uniformity, unearthing dust specks pre-plug.

Vigil veers to the vein’s variance. Monthly, meter end-to-end budgets for creep—swells over 2 dB cue cap cleans, reglossing faces in gritty groves to repel haze. Half-yearly, flex cables through duty arcs to vet micro-bends, charting drifts from age; in oily orbits, a solvent swab thwarts residue. Harvest OTDR sweeps quarterly to divine split equity, oft from unequal pulls, and align with TIA tests by faulting legs. These vigils, veined to vaults, vitalize the unit’s vein sans vowed voids, unveiling umbrage that ushers updates urbane.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626