Description

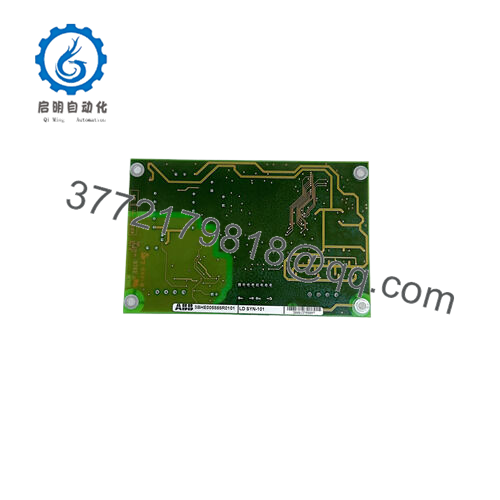

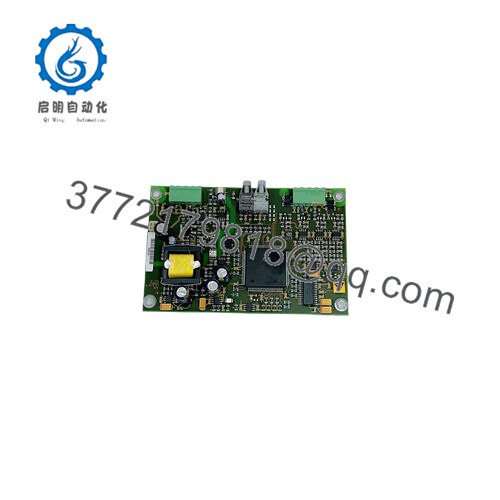

ABB LDSYN-101 3BHE005555R0101 Product Description:

ABB LDSYN-101 3BHE005555R0101 serves as a central data synchronization hub in the industrial automation ecosystem. It interfaces with multiple control platforms, including ABB’s own distributed control system (DCS) and programmable logic controller (PLC), as well as other third-party devices that support common industrial communication protocols. By utilizing these protocols, the module is able to receive data from multiple sources, analyze timestamps and content, and then distribute synchronized data packets to relevant destinations.

LDSYN-101 3BHE005555R0101

It is equipped with a high-speed processing unit that can process large amounts of data traffic with extremely low latency. This module also supports redundant communication paths, enhancing system reliability by providing backup options in the event of a main link failure. In terms of its position in the automation architecture, it is located between on-site sensors and actuators and advanced control and monitoring systems, serving as a critical intermediary to ensure all data synchronization. Its built-in diagnostic function continuously monitors the synchronization status, and once any differences or problems occur, it will immediately alert engineers, thereby promoting rapid troubleshooting and resolution.

LDSYN-101 3BHE005555R0101

Technical specifications:

Model ABB LDSYN-101 3BHE005555R0101

Brand ABB

Type data synchronization module

Working temperature range -10 ° C to 60 ° C

Interface/Bus Ethernet PROFIBUS DP、Modbus TCP

Certification CE, RoHS

Supports Ethernet/IP, Profinet, Modbus RTU, OPC UA protocols

Contact Us

Phone:+86 16626708626

Email: 3772179818@qq.com

WhatsApp/WeChat:+86 16626708626

LDSYN-101 3BHE005555R0101

Main features and advantages:

Choosing ABB LDSYN-101 3BHE005555R0101 brings significant advantages to industrial automation projects. Its high-speed data synchronization capability eliminates time delays, enabling real-time decision-making and precise control throughout the entire production or operation process. This improves production efficiency, reduces waste, and enhances product quality. For example, in pharmaceutical manufacturing facilities, accurate data synchronization ensures precise control of all manufacturing parameters and meets strict quality standards.

The redundant function of this module ensures continuous operation and minimizes the risk of expensive downtime to the greatest extent possible. In the event of communication link failure or hardware failure, redundant paths will automatically start to maintain data synchronization without any interference. Its compatibility with multiple industrial protocols reduces the complexity of integrating different devices and systems, saving a lot of engineering time and resources. In addition, the built-in diagnostic function simplifies maintenance work, allowing technicians to quickly identify and solve problems, thereby extending the service life of the module and reducing overall maintenance costs. Overall, ABB LDSYN-101 3BHE005555R0101 is a key driver in creating more reliable, efficient, and intelligent industrial automation systems.

LDSYN-101 3BHE005555R0101

Application areas:

ABB LDSYN-101 3BHE005555R0101 has been widely used in various industries. In the food and beverage industry, it ensures that all production equipment from mixers, filling machines to packaging machines can operate perfectly synchronously, optimizing production speed while maintaining product consistency. In a chemical processing plant, multiple chemical reactions and processes occur simultaneously, and this module enables real-time monitoring and control to prevent potential safety hazards and ensure efficient production.

In smart grid applications, it synchronizes data from numerous sensors, meters, and control devices in the electrical network. This helps to better manage power generation, distribution, and consumption, improving the overall stability and reliability of the power grid. In addition, in large-scale logistics and warehousing facilities, ABB LDSYN-101 3BHE005555R0101 coordinates the operation of automated guided vehicles (AGVs), conveyor systems, and inventory management systems to ensure seamless material handling and efficient order fulfillment.

LDSYN-101 3BHE005555R0101

Related products:

ABB LDSYN-201 3BHE005556R0101: Provides enhanced processing power and higher data throughput, suitable for data intensive applications.

ABB LDSYN-102 3BHE005557R0101: With additional communication interfaces, it provides greater network integration flexibility.

ABB LDSYN-301 3BHE005558R0101: Designed specifically for ultra-high speed data synchronization requirements in advanced manufacturing environments.

ABB LDSYN-103 3BHE005559R0101: As an affordable alternative, it has basic data synchronization capabilities and is suitable for small projects.

ABB LDSYN-202 3BHE005560R0101: Includes advanced diagnostic capabilities for deeper system monitoring and predictive maintenance.

ABB LDSYN-104 3BHE005561R0101: Provides an extended operating temperature range suitable for harsh industrial environments.

ABB LDSYN-302 3BHE005562R0101: With enhanced redundancy capabilities, it is suitable for mission critical applications that require 100% uptime.

Installation and maintenance:

Before installing ABB LDSYN-101 3BHE005555R0101, it is essential to thoroughly review the communication protocol settings of the existing control system and equipment to ensure compatibility. Verify whether the network infrastructure can support the data traffic requirements of the module, and check the power specifications to ensure a stable and appropriate power supply. When installing modules, follow the recommended guidelines to ensure proper ventilation and accessibility for future maintenance.

For continuous maintenance, the diagnostic indicator lights of the module should be regularly monitored to detect any signs of abnormal operation or data synchronization issues. Regularly clean the communication interface to prevent dust and debris from affecting signal quality. It is recommended to update the firmware of the module to the latest version provided by ABB, as firmware updates typically include performance improvements, security patches, and bug fixes. Perform routine system checks to verify the integrity of redundant communication paths, and conduct comprehensive testing annually to ensure that the module continues to meet the required performance standards.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626