Description

In the labyrinth of industrial automation, where the fusion of field-level measurements and central command systems demands unerring data fidelity amid electrical noise, thermal variances, and protocol mismatches, engineers often navigate a minefield of integration pitfalls that erode loop precision and inflate troubleshooting hours. Consider a semiconductor fabrication cleanroom, where laser-tracked wafer positions must sync with robotic arms—any jitter in distance signals could misalign etches, yielding defective chips that cascade into multimillion-dollar scrubs. Or envision a warehouse automation hub, riddled with conveyor drifts and forklift vibrations, where imprecise positional feedback triggers false halts, bottlenecking throughput in e-commerce fulfillment where seconds shave margins. These aren’t sporadic hiccups; they’re the entrenched frictions in process control landscapes, where high reliability in I/O signal paths hinges on sensors that deliver micron-level accuracy without the creep of environmental drift or the hassle of frequent recalibrations.

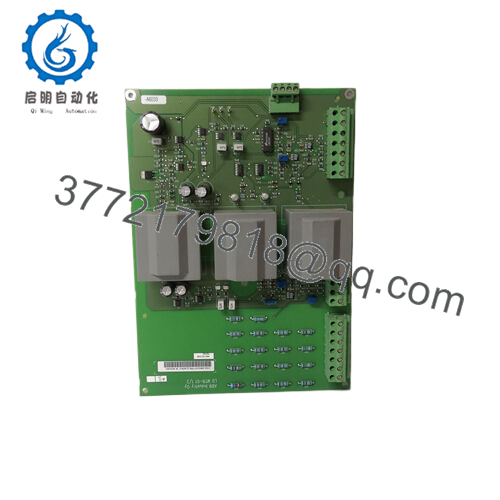

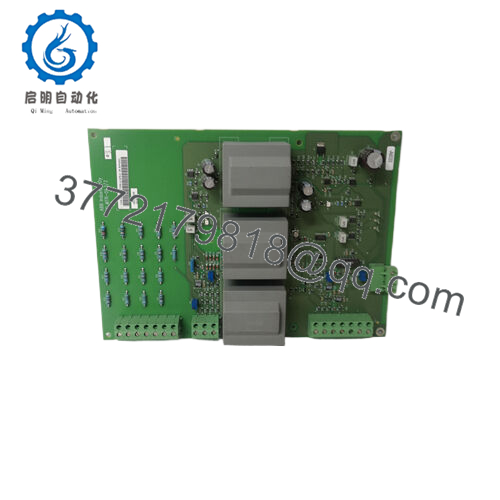

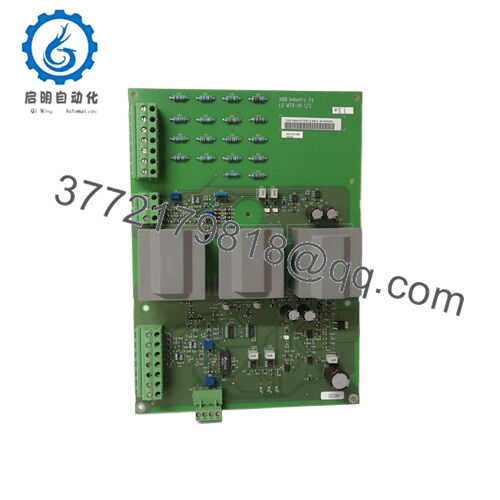

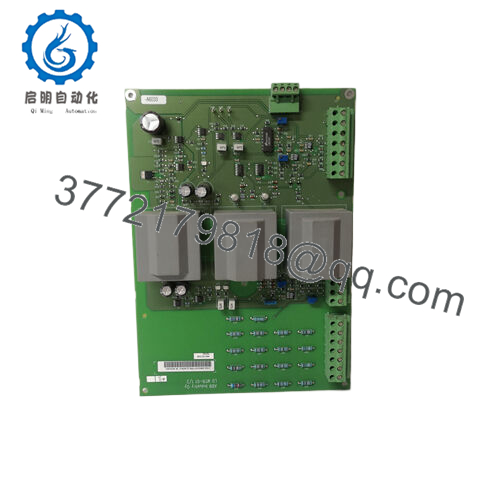

The ABB LDMTR-01 steps in as a laser distance measurement sensor, leveraging time-of-flight optics to capture non-contact positional data with laser-sharp resolution in ABB’s metrology suite. It targets the engineer’s core objective of seamless spatial monitoring, emitting a Class 2 laser beam to triangulate targets from 0.1 to 10 meters, outputting crisp 4-20 mA or RS485 signals that plug directly into DCS backplanes for real-time adjustments. In dynamic arenas like automated guided vehicles or quality inspection gantries, the ABB LDMTR-01 asserts its indispensability by filtering ambient light interference and vibration-induced wobbles, ensuring I/O signals remain pristine for closed-loop corrections that prevent overtravel or underreach. Its compact, IP67-sealed form factors sidestep the wiring mazes of legacy ultrasonic alternatives, channeling modular integration that trims deployment drag while upholding the high reliability your safety interlocks and yield trackers demand.

Engineers in the trenches prize the ABB LDMTR-01 for its no-frills fortitude in industrial automation—it’s the sensor that doesn’t just see but sustains, with adaptive algorithms that auto-compensate for dust motes or thermal lens shifts, letting you sustain sub-millimeter tolerances without constant tweaks. For retrofits in aging assembly lines, it bridges analog holdouts to Ethernet/IP overlays, dissolving the opacity of mixed-signal chains. At its heart, it empowers process control that’s anticipatory, not apologetic, quelling the positional variances that haunt defect logs and fortifying the uptime your operations etch in stone.

- LDMTR-01

The ABB LDMTR-01 embeds at the perceptual fringe of your automation hierarchy, projecting a modulated laser pulse to gauge echo returns via integrated photodiodes, then conditioning the phase differential into scalable analogs or digital packets that feed I/O architectures like ABB’s S800 series or third-party PLCs. It mounts via M6 threads or bracket kits in overhead or side-view configs, interfacing through a sealed M12 connector to backplane converters for Modbus RTU handoffs, where positional deltas trigger servo commands or alarm thresholds in under 1ms cycles. In a full stack, it pairs with signal isolators like the TPU2 for noise quarantine, its onboard MCU embedding edge filters that purge outliers before propagation to the controller core.

Interplay with companions is crisp: link to an LDSTA-01 calibration target, and it’s self-verifying reflectivity via NIST-traceable routines, while diagnostics stream via USB or Ethernet for HMI trending of beam divergence or target lock stats. Redundancy options include dual-beam failover for obscured paths, and its software suite—tuned through ABB Ability—auto-configures scan rates up to 100 Hz for high-velocity tracks. Nestled in the field-to-midlayer transition, the ABB LDMTR-01 scales from solitary gap checks to sensor constellations in 800xA meshes, its protocol breadth (PROFIBUS to EtherCAT) easing hybrids with legacy resolvers. For transitional rigs blending optics with inductive backups, it curtails fusion layers, so you orchestrate trajectories over orchestrating optics.

| Specification | Details |

|---|---|

| Model Number | LDMTR-01 |

| Brand | ABB |

| Type | Laser Distance Measurement Sensor |

| Input Voltage | 24 V DC |

| Operating Temp Range | -10°C to +50°C |

| Mounting Style | M6 Thread / Bracket |

| Dimensions | 53 x 125 x 260 mm |

| Weight | 0.7 kg |

| Interface/Bus | M12 Connector, RS485 |

| Compliance | CE, RoHS, IEC 60825-1 (Class 2 Laser) |

| Supported Protocols | Modbus RTU, PROFIBUS DP |

| Typical Power Draw | 2 W |

Opting for the ABB LDMTR-01 cements a reliability ethos forged for the flux of positional pursuits, where its dielectric-hardened optics and inertial damping hold beam coherence through EMI pulses or convective drafts, yielding performance consistency that anchors trajectories and nips collision risks before they dent chassis. In high-rep pick-and-place cells where micro-drifts compound into macro-misses, this means programmers who iterate paths with confidence, unshadowed by the hysteresis that haunts cheaper lidars—directly streamlining the cycles your takt times toast.

The deployment dividends unfold organically, paring engineering overhead by one-touch mounts that align via integral bubbles—deploy a fleet, and they’re profiling in a alignment pass, while plug-in cal kits like the LDSTA-01 distill verifications to field kits, not fab returns. Engineered for the span of assembly arcs, the ABB LDMTR-01 hones maintenance through spectral logs that herald lens fogs, elongating cleanings from shiftly scrubs to monthly mirrors and rerouting techs to variance hunts. In the fuller frame, it erects an automation armature that extends with your precision playbook, where stacking vision adjuncts atop laser lines deepens defect detection sans foundational fumbles, securing long-term performance that dovetails with opex orbits and scalability sails.

In automotive body shops, the ABB LDMTR-01 lasers door gaps on assembly jigs, clocking tolerances to 0.05 mm amid robotic sweeps—its vibration rejection ensures gap-free welds, upholding critical system uptime in process control crucibles where panel mismatches mar millions. Logistics sorters enlist it for parcel dimensioning on belts, its 100 Hz scans syncing diverters for route fidelity; here, IP67 grit-proofing counters debris flurries, delivering high reliability for throughput that hits holiday surges without sort stalls.

Aerospace composites cap its chorus, tracking layup contours in autoclave preps where thermal bows test every tick—the sensor’s compensation curves maintain veracity, integrating into DCS for oversight that sustains continuous uptime amid the exacting ethos of process control environments that brook no fiber flaws.

LDMTR-30 – Extended-range kin for 10-50m spans in gantry or crane positionals.

LDMUI-01A – Configurator module with baked-in LDSTA-01 cal for setup streamlining.

LDSTA-01 – Reference target companion for in-situ reflectivity baselines.

LD-ALIGN-01 – Alignment jig add-on for multi-sensor optical harmonies.

TPU2 – Signal conditioner variant for analog uplift in noisy I/O chains.

PCD300 – Metrology controller base for fused laser-inductive loops.

LDMTR-02 – Compact sibling for tight-space, short-throw measurements under 1m.

Before bolting the ABB LDMTR-01 into your gantry, plumb the beam path with a theodolite—offsets over 0.2° spawn cosine skews, so shim per ABB’s datum charts and shadow-test against specular bounces. Seal M12 glands to IP67 in vapor vaults, and log ambient RH below 85% to dodge condensation curls; pair with a power ripple scan under 50 mV to nix modulation murk. Firmware fusion finishes: snag the optics-optimized drop from ABB’s lair, mate to your bus revision, and mimic a target sweep on a shadow rig to vet lock thresholds pre-live.

In the run rhythm, husbandry hugs acuity over excess. Biweekly beam logs via port polls can unearth divergence drifts, queuing a lens swab before blur bites. Quarterly, untwist for mount audits, aligning with feeler gauges and re-torquing to 5 Nm in shake zones. Frame annual with cal cycles: engage the LDSTA-01, retune if wander tops 0.1 mm, and stash spectra for decay divines like diode dimming. These cadences cull the sensor’s smarts to prolong your industrial automation’s gaze, rendering regimen a reflex, not a recoil.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626