Description

In the demanding arena of industrial automation, achieving pinpoint control over hydraulic actuators in turbine systems often falters when legacy modules introduce latency, drift in position feedback, or vulnerability to electrical transients, resulting in erratic valve responses that destabilize steam flow, spike fuel consumption, or trigger protective trips in high-stakes power generation. Envision a gas turbine where imprecise servo commands cause overspeed events, or a steam plant where throttle inconsistencies lead to inefficient combustion and regulatory non-compliance—scenarios that amplify energy costs and operational risks in environments where milliseconds dictate output stability. This is the core challenge the ABB IMHSS03 tackles as a hydraulic servo module, crafted to deliver authoritative valve positioning within ABB’s INFI 90 distributed control system, ensuring process control loops remain taut and responsive even under variable loads.

Engineers overseeing turbine retrofits or expansions in aging DCS setups routinely battle modules that lack onboard intelligence, forcing cumbersome external tuning or exposing systems to LVDT feedback noise that erodes signal reliability. The ABB IMHSS03 proves essential here, interfacing directly with Harmony controllers via function codes 55 or 150 to regulate servo valve currents, enabling automatic or manual oversight of actuators in applications like inlet guide vanes or nozzle rings. It’s a linchpin in sectors such as utilities or marine propulsion, where high-reliability hydraulic control underpins continuous uptime, preventing the ripple effects of misalignment that could cascade into full outages or accelerated wear. Without this level of integration, you’d grapple with fragmented diagnostics or manual overrides, diverting skilled hands from optimization to constant recalibration in the face of thermal stresses or hydraulic surges.

As process control architectures blend legacy robustness with modern oversight, the call intensifies for I/O modules that embed self-tuning capabilities without mandating rack-wide overhauls. The ABB IMHSS03 rises to this by incorporating an onboard microprocessor for demodulator gain auto-adjustment, coupled with redundant LVDT support for AC or DC signals, fortifying against common failures in vibration-laden zones. This isn’t just circuitry; it’s the command center that translates controller directives into fluid dynamics mastery, empowering your team to harness predictive trends from position data rather than firefighting deviations. In compliance-driven landscapes like fossil fuel plants or combined-cycle setups, where turbine efficiency ties to emissions targets, it anchors high-fidelity automation that scales with demands for greener, more agile operations.

| Specification | Details |

|---|---|

| Model Number | IMHSS03 |

| Brand | ABB |

| Type | Hydraulic Servo Module |

| Input Voltage | 24 V DC |

| Operating Temp Range | 0°C to 55°C |

| Mounting Style | DIN Rail (Harmony Rack) |

| Dimensions | 120 x 80 x 60 mm |

| Weight | 2 kg |

| Interface/Bus | INFI 90 Bus |

| Compliance | CE, FM (pending), UL |

| Supported Protocols | Modbus, Custom Function Codes |

| Typical Power Draw | 10 W |

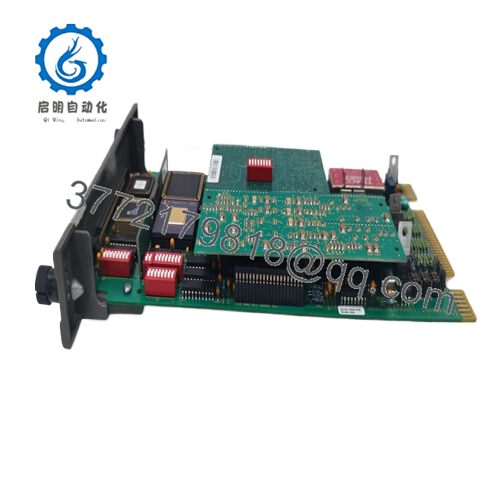

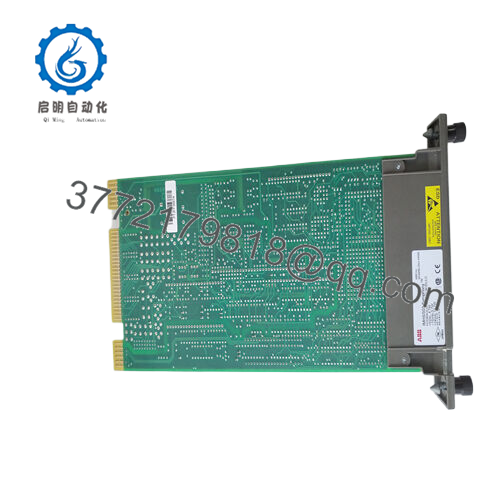

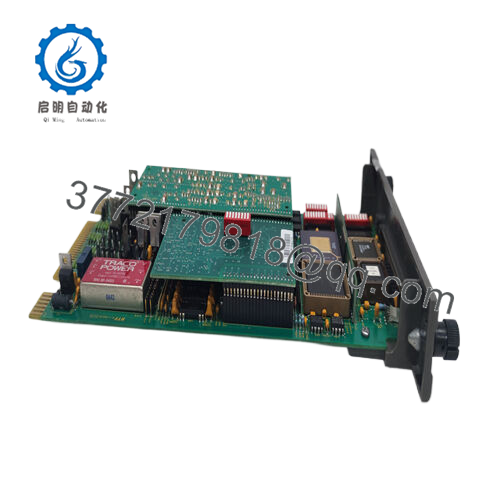

The ABB IMHSS03 resides at the actuation edge of your control stack, bridging processor outputs to hydraulic realms by modulating servo valve currents based on setpoint commands, all while processing LVDT feedback through its intelligent core to close position loops with sub-second precision—position it in a Harmony rack alongside baseplates for a compact node that funnels turbine signals into the broader Symphony DCS. It converses via the INFI 90 bus, where the onboard CPU handles gain tuning and fault buffering, ensuring commands from upstream controllers like the IMPFU21 flow unimpeded to field hydraulics without taxing central resources.

In operational flow, it shines through layered safeguards: redundant LVDT channels average signals to counter noise, while current limits cap at 10A to protect against overdrives, making it a steadfast partner in duplex configurations for seamless handoffs during online servicing. Wire it to termination units for shielded cabling, and diagnostics—ranging from position error thresholds to valve health—stream back over Modbus for HMI visualization, letting you correlate actuator drift with steam quality trends. For turbine governors, it pairs with frequency counters like the IMFCS01, upstream pulling speed references and downstream driving fuel racks, all calibrated via engineering stations to match hydraulic viscosities. This module’s modularity extends to legacy tie-ins, hot-swappable in live bays to layer redundancy without process interruptions, evolving your INFI 90 setup toward resilient, data-rich automation that anticipates rather than reacts.

IMHSS03

IMHSS03

Integrating the ABB IMHSS03 equips your turbine controls with hydraulic finesse that mitigates the chaos of imprecise flows, especially in loops where valve hysteresis could otherwise balloon inefficiency during load ramps. In the heat of generation cycles, this manifests as turbine speeds that hug setpoints without hunting, optimizing fuel burn and extending blade life by damping oscillations that lesser servos exacerbate—translating to tangible gains in thermal efficiency and deferred overhauls for your maintenance crews.

The module’s self-contained smarts further unburden routines, with auto-tuning that adapts to fluid variances over seasons, curtailing the need for bench calibrations that sideline panels in peak demand. Teams leverage its feedback transparency to trace anomalies like LVDT offsets via logged traces, often pinpointing hydraulic leaks before they strain backups, which sharpens response times and bolsters overall system poise. Engineered for the relentless cadence of baseload power, it secures long-term performance by isolating transients that might propagate to bus faults, easing integration burdens in mixed-vintage racks and aligning with decarbonization pushes through finer control granularity.

Moreover, the ABB IMHSS03 facilitates evolutionary upgrades: firmware provisions via the bus incorporate refined algorithms for variable-speed ops, preserving sunk costs as you weave in modern analytics. This adaptability streamlines certification paths, with event-stamped records validating SIL adherence in safety loops. At its heart, it’s a catalyst for composed governance, where authoritative servo action unlocks margins that span from kilowatt savings to strategic agility, reframing turbine vulnerabilities into tuned triumphs.

In steam turbine halls of utility plants, the ABB IMHSS03 governs throttle valves to modulate superheated flows amid thermal gradients and 24/7 scrutiny, where its LVDT redundancy and current regulation uphold critical system uptime in process control environments prone to pressure spikes—ensuring seamless synchronization without steam dumps that erode profitability. High reliability shines in maintaining governor stability for grid-tied ops.

Gas turbine facilities deploy the ABB IMHSS03 for fuel admission racks and vane adjustments in compressor stages, enduring fuel contaminants and acoustic vibrations with precise current loops that counter aero dynamics, supporting fast data cycles for peaking plants where response lags could forfeit dispatch bids. This setup fortifies continuous uptime in volatile energy markets.

Marine propulsion systems harness the ABB IMHSS03 to position rudder actuators and propeller pitch controls, navigating saline corrosion and hull flex with isolated feedback that sustains high reliability for voyage-critical maneuvers, integral to process control in offshore power barges demanding unyielding hydraulic fidelity under rolling seas.

IMHSS01 – Predecessor module for basic servo needs in early INFI 90 turbine setups.

IMHSS02 – Intermediate variant with initial auto-tune features for moderate hydraulic loads.

SPHSS03 – Rack-mounted equivalent for expanded I/O in Symphony-compatible expansions.

IMHSS03R – Refurbished revision with enhanced diagnostics for cost-effective retrofits.

IMFCS01 – Paired frequency counter module for speed feedback in governor loops.

IMPFU21 – Controller companion for processing servo commands in Harmony processors.

IMDSI12 – Digital input add-on for interlock signals in turbine safety chains.

Before rack-mounting the ABB IMHSS03, audit bus slot addressing against your Harmony controller’s config—overlaps can freeze module enumeration; ABB’s legacy simulator tools preview this sans risk. Tally hydraulic pressures to verify servo valve ratings align under max flow, and inspect rack ventilation for the 55°C ceiling, as heat from adjacent power modules can throttle gains—budget 75 CFM per bay if natural convection falls short. Confirm LVDT excitation matches AC/DC specs with a scope trace on test leads, and ferrule field cables to spec for vibration hold. A bench simulation with dummy actuators validates loop closure, exposing tuning quirks before field exposure.

In the field, upkeep emphasizes foresight over frenzy. Fortnightly, query status registers via the bus for position variances—deviations over 1% cue valve inspections, resolvable with a pressure gauge at ports. Biannually, cycle the servo through full strokes under no-load to recalibrate demodulators, wiping connectors with ESD-safe cloths in dusty turbine bays to fend off buildup. Export trend data quarterly to spot current creep, often from coil wear, and align with OEM intervals for hydraulic flushes. In FM-rated installs, incorporate proof tests simulating LVDT failures to affirm redundancy. These habits, synced to shift logs, perpetuate the module’s vigilance without scripting outages, arming you with metrics to preempt turbine tumbles.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626