Description

Real-World Use & Application Scenarios

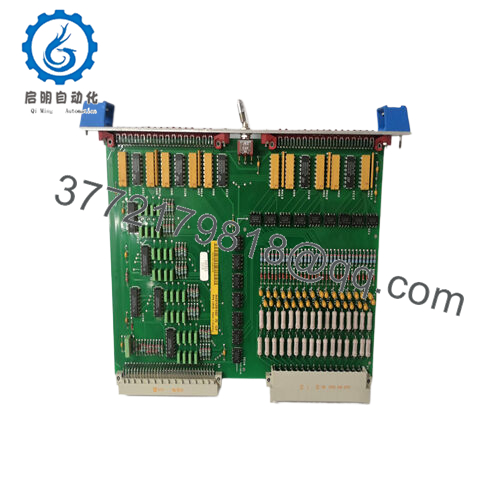

The ABB IDPG 940128102 is a versatile control module widely employed in industrial automation sectors that demand precise signal processing and robust control. It is frequently found in power generation plants, petrochemical facilities, and large-scale manufacturing installations where accurate input/output signal handling is essential to maintaining system reliability. This module is designed to manage complex digital signals such as switch statuses and sensor data, providing dependable control outputs in challenging industrial environments.

Used extensively in industrial automation, the ABB IDPG 940128102 supports control system applications that call for custom digital signal processing, ensuring operational precision and fault tolerance. Its role is crucial in distributed control systems (DCS) where multi-channel input/output processing facilitates comprehensive monitoring and control solutions. This module is particularly applicable in scenarios requiring high data throughput and predictive diagnostics in automated production lines.

Engineers rely on the ABB IDPG 940128102 for its stability and adaptability in control systems where maintaining signal integrity under harsh conditions is paramount. The module’s ruggedness and advanced processing capabilities enhance control architectures, enabling better responsiveness and improved automation efficiency.

Product Introduction & Positioning

The ABB IDPG 940128102 is a high-performance digital signal processing module tailored for distributed control system integration. It acts as an intelligent input/output (I/O) processing unit that consolidates and interprets multiple digital signals, allowing precise control actions based on real-time data. In ABB’s automation framework, this module occupies a central position within control racks, interfacing between field instrumentation and supervisory control layers.

As a programmable logic controller (PLC) component, the ABB IDPG 940128102 offers extensive customization options, supporting specialized processing tasks beyond generic control needs. Its modular design and communication flexibility ensure easy integration into larger ABB control systems or third-party platforms using standard protocols. This adaptability makes it highly valued by system integrators aiming to deliver tailor-made automation solutions.

The ABB IDPG 940128102 provides engineers with diagnostic tools and predictive maintenance data to anticipate faults and optimize system uptime. By enabling detailed monitoring alongside advanced control logic, it contributes significantly to sustaining efficient plant operations across diverse industries.

- IDPG 940128102

Key Technical Features & Functional Benefits

With a robust 500 MHz digital signal processor core, the ABB IDPG 940128102 delivers superior processing speed and accuracy, capable of handling 16-bit resolution input channels to capture fine signal variations. It incorporates 512 MB RAM and 4 GB flash memory, enabling complex algorithms and operational data storage for enhanced automation tasks.

This module boasts a rugged construction with an IP67-rated enclosure, protecting against dust and water ingress, making it suitable for the harshest industrial conditions while maintaining stable operation across wide temperature ranges. Its compact size supports dense control rack configurations, saving valuable cabinet space.

The ABB IDPG 940128102 supports customizable I/O configurations with a scalable channel count, allowing flexible adaptation to various control needs. Advanced diagnostic functions facilitate predictive maintenance, reducing unplanned downtime by identifying potential issues early through comprehensive system feedback.

Interfacing capabilities include industry-standard communication protocols, ensuring seamless connectivity with ABB’s Distributed Control System or other SCADA platforms. This promotes real-time data exchange and remote configuration, enhancing overall system intelligence and operational control.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | IDPG 940128102 |

| Brand | ABB |

| Product Type | Digital Signal Processor Module |

| Processing Speed | 500 MHz DSP Core |

| Input Channels | 16-bit resolution, multi-channel |

| Memory | 512 MB RAM, 4 GB Flash Storage |

| Operating Voltage | 24V DC |

| Operating Temperature | -25 to +70 °C |

| Enclosure Protection | IP67 (Water and Dust Resistant) |

| Dimensions (W x H x D) | 152 x 51 x 203 mm |

| Weight | Approx. 1.2 kg |

| Communication Protocols | Modbus RTU, PROFINET |

| Certifications | CE, UL, IEC Standards |

Related Modules or Compatible Units

216BM61B – Advanced process control module often paired to extend system functionality.

PCD235B1101 – Excitation control unit compatible with signal processor modules.

OCAH 940181103 – Programmable output control module complementing input processing capabilities.

REG216 – Protection relay used in conjunction with processor modules for system safety.

BMS611B06 – Circuit protection module safeguarding automation electronics.

230SM – Modular control system compatible with ABB control components.

Installation Notes & Maintenance Best Practices

When installing the ABB IDPG 940128102, verify that the control panel provides a clean, vibration-minimized space with adequate ventilation suited to its IP67 rating. Ensure proper grounding and shield all connecting cables to minimize electromagnetic interference that could impact signal processing fidelity. Adequate clearance for accessing connectors and future maintenance should be planned in the automation cabinet layout.

Maintenance should focus on periodic inspection of module connections, firmware updates to leverage continual improvement, and diagnostics via integrated communication protocols. Proactive monitoring of system parameters combined with predictive maintenance alerts helps anticipate and resolve issues before causing downtime, extending the module’s operational life.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626