Description

In the rugged expanse of industrial automation, where the accurate capture of analog signals from sensors and transmitters forms the bedrock of process monitoring and control, engineers routinely battle issues like signal noise from long cable runs, ground potential differences causing measurement errors, or scalability limits that force fragmented I/O layouts, leading to skewed data that cascades into inefficient loops or safety margins eroded by false readings. Consider a water treatment plant where pH probes and flow meters must relay precise levels amid corrosive brine and electromagnetic hum—any drift in analog inputs could misdose chemicals, compromising effluent quality and inviting fines in regulated process control environments where every ppm deviation hits compliance ledgers. Or envision a food processing line, vibrating with conveyor rhythms and steam bursts, where temperature and pressure signals feed PID controllers; imprecise I/O handling risks overcooking batches or pressure spikes, amplifying scrap rates and recall risks in setups demanding unyielding fidelity for throughput and traceability. These aren’t fleeting faults; they’re the entrenched exposures in high-reliability systems, where modular analog input boards must deliver clean, isolated signal paths to sustain responsive automation without the engineering slog of custom shielding or frequent zero-drifts.

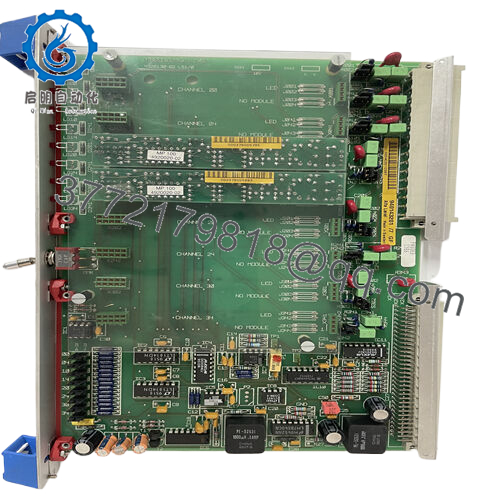

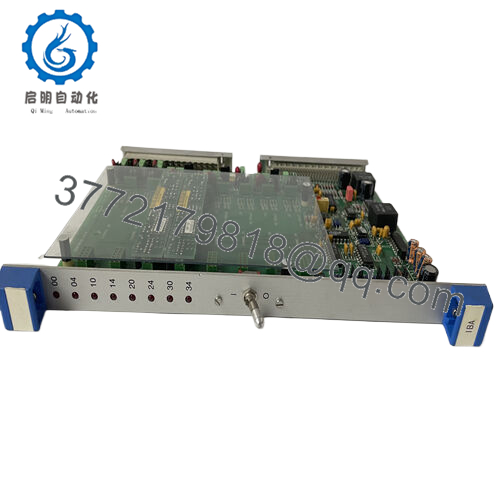

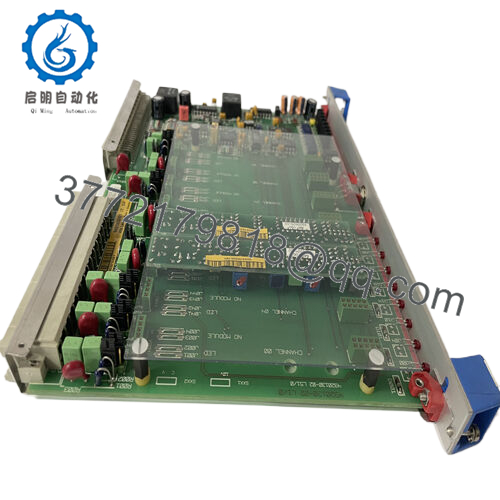

The ABB IBA 940143201 steps up as a robust analog input board in ABB’s IBA (Industrial Backplane Architecture) series, tailored for integration into DCS and PLC frameworks like AC 800M or legacy SattControl systems. It zeroes in on the engineer’s goal of versatile signal acquisition, supporting multi-range 4-20 mA, 0-10 V, or thermocouple inputs across 8-16 channels (configurable), with 16-bit resolution for capturing process variables like temperatures up to 1200°C or pressures to 100 bar without attenuation. In demanding scenarios such as batch reactors or remote monitoring skids, the ABB IBA 940143201 becomes vital, its galvanic isolation (up to 1500 V) and low-noise preamps ensuring signal integrity over 1 km runs, while DIN-rail compatibility enables hot-swappable expansions without halting lines. By prioritizing built-in diagnostics for channel health and overrange alerts, it trims the frustration of intermittent faults, channeling pristine I/O signals that bolster process control loops for tighter tuning and fewer interventions, all while meeting SIL 2 nods for safety-critical chains.

What makes the ABB IBA 940143201 a steadfast ally in industrial automation is its unassuming universality—it’s the board that adapts without attitude, with jumper-selectable ranges and HART passthrough that lets you layer smart diagnostics onto legacy 4-wire setups, freeing teams to chase optimizations over offset hunts. For retrofits in aging panels, it slots into SattControl or Advant backplanes to bridge analog relics with Ethernet overlays, curbing the opacity of mixed-signal sprawl. In essence, it empowers process control that’s not just sampled but steadfast, quelling the noise that nibbles at accuracy and upholding the high reliability your yield forecasts and audit trails require.

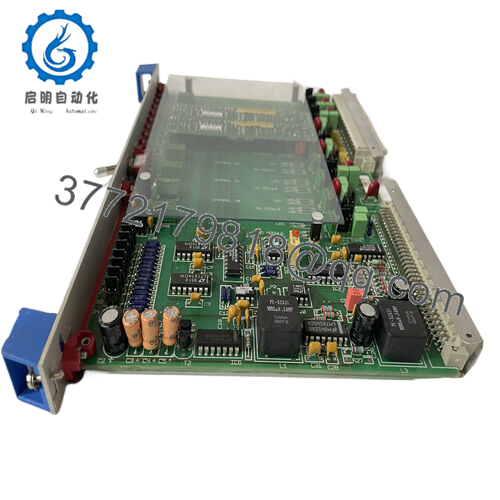

The ABB IBA 940143201 integrates at the signal front in your automation stack, snapping onto IBA or S800 backplanes to ingest analog vignettes from field transducers—RTDs, thermocouples, or current loops—via screw terminals or pluggable TU units, where per-channel ADCs digitize with 24-bit sigma-delta conversion, multiplexing them onto the CEX bus for CPU ingestion at up to 100 Hz rates. It thrives in ABB’s 800xA or Freelance ecosystems, where inputs propagate as scaled values to function blocks for filtering or alarming, supporting cold junction compensation for Type K/J thermocouples out of the box. In a typical enclosure, it mounts alongside power modules, its firmware—tuned via Control Builder—auto-calibrating spans on boot, while EMI filters (per IEC 61000-4) quarantine spikes before backplane handoff.

System synergy flows naturally: pair it with an AI845 expander for denser arrays, and it’s validating linearity in a scan, with status relays pulsing faults to HMIs for triage. Diagnostics embed via ABB’s tools, surfacing metrics like input impedance or crosstalk via loopback tests, and its redundancy schema—duplex channel mirroring—clamps dropouts to single points. Leaning into the lower I/O tier, the ABB IBA 940143201 excels in distributed cabinets, scaling from 16 to 256 channels in modular racks, its Modbus TCP extensions easing ties to third-party historians. For hybrid plants blending analog holdouts with digital sensors, its range agility minimizes scaling scripts, so you refine PID gains over chasing calibration quirks.

- IBA 940143201

| Specification | Details |

|---|---|

| Model Number | IBA 940143201 |

| Brand | ABB |

| Type | Analog Input Board |

| Input Voltage | 24 V DC |

| Operating Temp Range | -20°C to +60°C |

| Mounting Style | DIN Rail / Backplane |

| Dimensions | 120 x 90 x 45 mm |

| Weight | 0.4 kg |

| Interface/Bus | CEX Bus |

| Compliance | CE, RoHS, IEC 61131-2, SIL 2 |

| Supported Protocols | Modbus TCP, HART Passthrough |

| Typical Power Draw | 3 W |

Selecting the ABB IBA 940143201 lays a reliability foundation calibrated for the flux of field feeds, where its isolated barriers and thermal tracking lock in measurement verity through EMI pulses or convective curls, yielding performance consistency that steadies variables and nips the drift that derails decisions. In sensor chains snaking through steam vaults, this means technicians who zero quarterly, not weekly, with auto-compensation that sidesteps junction jitters—directly paring the variance logs your quality metrics magnify, without the veil of vague voltages.

The assimilation advantages accrue organically, lightening engineering overhead by jumper-free configs in Control Builder; provision multi-range channels, and they’re profiling in a power cycle, while per-channel LEDs turn hunts into highlights. Engineered for the span of DCS dynasties, the ABB IBA 940143201 refines maintenance through runtime audits that trend offsets, elongating spans from shiftly scrubs to semestral scans and rerouting ranks to loop logics. In the grander grid, it nurtures an automation weave that widens with your analog ambitions, where appending smart HART atop basic loops deepens diagnostics without bus burdens, ensuring long-term performance that tallies with fiscal frames and failover finesse.

In chemical distillation columns, the ABB IBA 940143201 conditions thermocouple feeds for temperature cascades, sampling at 50 Hz to counter reflux swings—its isolation ensures spec holds, upholding critical system uptime in process control crucibles where deviations dent distillate dollars. Wastewater aeration tanks deploy it for pH/conductivity inputs, its HART passthrough mirroring probe health amid sludge static; here, high reliability thwarts electrode erosion, enabling precise blowers that meet discharge norms without dosing doubts.

Pharma fermenters complete the triad, multiplexing RTDs in sterile suites where the board’s resolution clocks broth viscosities—the module’s backplane backbone feeds SCADA for batch oversight, bolstering continuous uptime amid the rigorous rite of process control environments that prize ppm proofs over presumption pitfalls.

IBA 940143202 – Enhanced variant with 24 channels for denser analog arrays in monitoring-heavy setups.

AI810 3BSE008516R1 – Analog input module companion for basic 4-20 mA expansions.

AI880A01 3BSE042236R2 – High-density alternative for multi-range thermocouple integrations.

DO801 3BHE014070R0001 – Discrete output pair for analog-driven alarm signaling.

TU830V1 3BSE013234R1 – Terminal unit add-on for secure field wiring in I/O racks.

PM861AK01 3BSE018157R1 – CPU host for enhanced processing in AC 800M analog chains.

AI845 3BSE023676R10 – RTD-focused expander for temperature-centric process loops.

When preparing to rack the ABB IBA 940143201, first map your channel types against the board’s jumpers—mismatched ranges can skew spans, so tally transducer specs and set per ABB’s pinout charts to avoid attenuation. Allocate sufficient cabinet space for airflow, as the module dissipates heat under full load; a simple thermal audit using your enclosure’s specs will flag any risks, especially in enclosed setups where ambient skews toward the hotter end. Firmware alignment is key too: pull the current release from ABB’s resource library and match it to your controller’s version, testing a bench simulation if possible to validate signal handoff.

Post-installation, maintenance revolves around vigilance without excess effort. Bi-monthly checks of the status LEDs can reveal early signs of channel saturation, prompting a quick loop resistance test with a multimeter. For sites with high humidity, inspect sealed connectors semi-annually, re-torquing to spec and swapping if corrosion shows. An annual full diagnostic run—leveraging ABB’s diagnostic tools to log input traces—helps trend performance, catching drifts like gradual noise buildup before they affect your process control loops. These routines, grounded in the board’s self-reporting capabilities, keep your industrial automation humming reliably, turning potential weak points into strengths.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626