Description

Description:

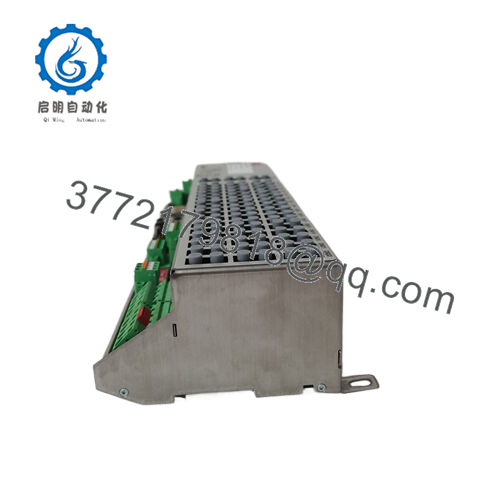

ABB GFD233A103 3BHE022294R0103 is a critical component in high-voltage power distribution and industrial motor control systems, where precision and fail-safe operation are paramount. It’s commonly deployed in steel mills, mining operations, and large-scale water pumping stations—environments where abrupt motor failures can lead to catastrophic downtime.

ABB GFD233A103 3BHE022294R0103

What makes this module indispensable is its dual channel Sin/Cos interface, which provides redundancy for critical processes. Unlike standard encoders, it can provide sub degree accuracy even at speeds close to zero, which is crucial for controlling cranes and elevators in ports. Its plug and play design simplifies the transformation and seamlessly integrates with existing drive cabinets without the need for reconfiguration.

ABB GFD233A103 3BHE022294R0103

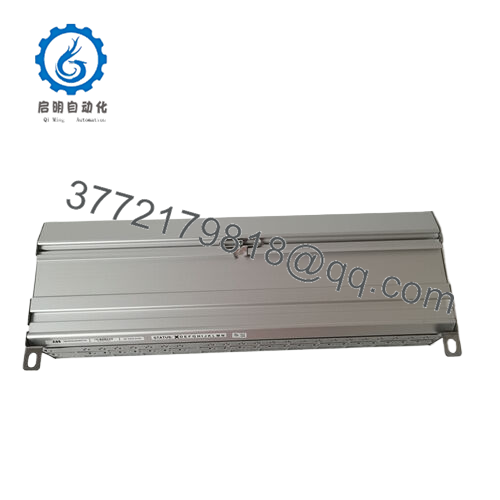

Technical specifications:

Model | ABB GFD233A103 3BHE02294R0103

|Brand | ABB

|Type | Feedback Interface Module

|Input voltage | 24 VDC (± 15%)

|Working temperature | -40 ° C to+70 ° C

|Installation | DIN rail or panel installation

|Size | 50 x 115 x 122 millimeters (width x height x depth)

|Weight | 0.7 kilograms

|Signal type | parser Sin/Cos、SSI

|Certified UL 508, CE, IEC 61800-5-1

|Isolation voltage 2.3 kV (input to output)

|Environmental grade IP54 (with optional kit)

Contact Us

Phone:+86 16626708626

WhatsApp/WeChat:+86 16626708626

Email: 3772179818@qq.com

ABB GFD233A103 3BHE022294R0103

Application areas:

ABB GFD233A103 3BHE02294R0103 is a critical component in high-voltage distribution and industrial motor control systems, where precision and fault safe operation are crucial. It is typically deployed in steel mills, mining operations, and large water pumping stations, where sudden motor failures can lead to catastrophic shutdowns.

One of its key applications is the conveyor belt system used for handling bulk materials. For example, in coal mines, this module ensures smooth torque control during start stop cycles, preventing belt slippage or mechanical stress. It also exists in cement plants, synchronizing multiple kiln drivers to maintain consistent speed. For engineers, ABB GFD233A103 3BHE02294R0103 solves the problem of harmonic distortion in variable frequency drives (VFDs), which is a common issue in factories with aging electrical infrastructure.

ABB GFD233A103 3BHE022294R0103

Main features and advantages:

ABB GFD233A103 3BHE02294R0103 achieves excellent noise resistance through differential signal processing. This eliminates erroneous triggering in environments with electrical noise such as electric arc furnaces. This module supports a rotating transformer frequency of up to 10 kHz and can accurately control the high-speed spindle in CNC machining centers.

Hardware robustness is another prominent point. Even when installed near the drive unit in a narrow casing, the anodized aluminum casing can effectively dissipate heat. Its screw terminal design can resist vibration loosening, which is a common pain point in pulp mill applications. Compatibility is not limited to ABB drives, it also interfaces with third-party PLCs through SSI outputs, which is a feature appreciated by factory integrators during phased automation upgrades.

The conformal coating supports long-term reliability and can withstand up to 95% humidity without condensation. In sugar factories where corrosive dust is commonly present, on-site data shows that the normal operating time during a 5-year deployment is 99.8%. The self diagnostic function of this module includes automatic adjustment of signal amplitude and reduction of maintenance intervention.

ABB GFD233A103 3BHE022294R0103

Related product introduction:

GFD233A101- Single channel version for non redundant applications.

3BHE039203R0101- Enhanced version supporting EtherCAT.

GINT561- Gateway module for Profibus DP integration.

GUD321- A universal drive interface for multi brand settings.

Installation and maintenance:

Preparation before installation: When installing ABB GFD233A103 3BHE02294R0103, maintain a distance of at least 30 centimeters from the power cord to prevent electromagnetic interference. Use twisted pair shielded cable (Belden 8761 is recommended) for the parser connection, and only ground the shielding at the driver end. Before debugging, verify whether the excitation voltage matches the rated value of the rotary transformer (usually 7 Vrms).

Maintenance suggestion: Please monitor the Status LED – stable yellow indicates signal degradation, which is usually caused by aging of the parser cable. Clean the wiring terminals with isopropanol every year to prevent the accumulation of contact resistance. The firmware update provided by DriveWindow Lite can optimize the signal filtering algorithm for specific motor types.

Other models of ABB series:

TVOC-2-240

TVOC-2-240 1SFA664001R1001

TVOC-2-240-C

TVOC-2-DP6 1SFA664003R1060

TVOC-2-E1

UAC383AE01 HIEE300890R0001

UAC389AE02 HIEE300888R0002

UAD142A01 3BHE012551R0001

UAD155A0111 3BHE029110R0111

UBC717BE101 3BHE021887R0101

UFC718AE01 HIEE300936R0001

UFC718AE101 HIEE300936R0101

UFC719AE 3BHB003041R0101

UFC719AE01 3BHB000272R0001

UFC719AE101 3BHB00072R0101

UFC765AE102

UFC911B104 3BHE037864R0104

UFC911B106 3BHE037864R0106

UFC911B108 3BHE037864R0108

UFC912A101 3BHE039426R0101

UFC921A 3BHE024856P106

UNC4673A HIEE205014R1

UNC4673AV1 HIEE205014R1

UNITROL 1010-0003 3BHE035301R410

UNITROL 1000 3BHE014557R0003

Unitrol 1000-7

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626