Description

What This Product Solves

The ABB FPR3203526R1002A is a critical module designed to address the challenge of maintaining reliable, continuous operation in industrial automation environments, particularly those that demand high availability and precise control. In complex process control systems, such as distributed control systems (DCS) and legacy automation setups, ensuring stable communication between controllers and I/O subsystems is fundamental. This product becomes essential where system stability, deterministic communication timing, and ease of maintenance are priorities. When downtime is costly and interruptions cannot be tolerated, the ABB FPR3203526R1002A helps sustain high reliability and modular integration, keeping production lines and power plants operating smoothly.

Industries that rely on continuous process plants—such as power generation, oil & gas, chemicals, and metals processing—demand robust hardware that can seamlessly fit into existing infrastructure while preventing communication bottlenecks. The ABB FPR3203526R1002A is engineered to support these goals by acting as a backbone communication and control interface module. It ensures process control signals and I/O data flow without delay or error, crucial for fast data cycles and critical system uptime. As a plug-in replacement or upgrade, this product also supports plant life extension strategies, avoiding the need for costly system redesigns while improving signal reliability on legacy ABB control platforms.

How the Product Works & Fits into a System

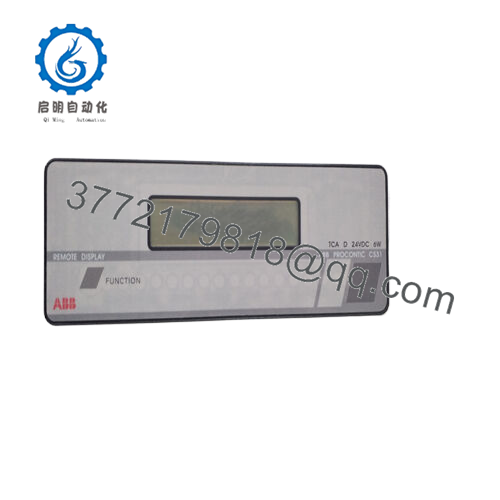

The ABB FPR3203526R1002A acts as a controller and communication interface module that fits into ABB’s classic distributed control system backplanes. Think of it as a communication hub that coordinates data exchanges between the central processor and various I/O modules responsible for field signal acquisition and control output. This module slides into a Eurocard-style rack, drawing power from the backplane and minimizing external wiring complexity.

Within the automation stack, the module resides in the control rack’s backplane slot, bridging communication protocols and ensuring deterministic bus timing—critical for maintaining process integrity in closed-loop controls. It supports on-board diagnostics through status LEDs that enable technicians to quickly assess system health during troubleshooting or routine maintenance. The module is commonly deployed in ABB’s legacy architectures such as the Procontrol/Advant systems where it interfaces with digital and analog I/O subsystems, drives, and other industrial devices.

Designed for 24/7 operation in harsh industrial conditions, the ABB FPR3203526R1002A supports reliable data throughput and seamless integration without requiring firmware or application logic changes. Its compatibility with established ABB system buses and communication protocols helps reduce engineering overhead and technical risk, making it an ideal choice for plants focused on long-term process stability and lifecycle support.

Technical Highlights Summary (Table)

| Specification | Details |

|---|---|

| Model Number | FPR3203526R1002A |

| Brand | ABB |

| Type | Controller/Communication Module |

| Input Voltage | Backplane-powered (Typically 24 V DC) |

| Operating Temp Range | 0 to +55 °C |

| Mounting Style | Slide-in Eurocard Rack Module |

| Dimensions | Approx. 6U x 160 mm depth |

| Weight | Around 0.4 to 0.7 kg |

| Interface/Bus | ABB proprietary system bus via backplane |

| Compliance | Industry-standard safety and EMC |

| Supported Protocols | ABB legacy DCS communication buses |

| Typical Power Draw | Low voltage DC supplied through backplane |

FPR3203526R1002A

Real-World Benefits

Choosing the ABB FPR3203526R1002A means selecting a product engineered for continuous, reliable operation in demanding industrial environments where consistent process control is non-negotiable. This module ensures long-term performance by mitigating common communication failures that can disrupt system cycles and cause unplanned downtime. Its robust design and adherence to ABB’s stringent quality standards reduce maintenance frequency and extend lifecycle, lowering total cost of ownership for plant operators.

In practical terms, the ABB FPR3203526R1002A reduces engineering overhead because it integrates smoothly with existing ABB system architectures without requiring extensive reconfiguration or application changes. Its on-board diagnostics enhance maintenance efficiency by supporting fast fault isolation, which helps operators minimize response time during unscheduled events or preventive maintenance checks. The unit’s compatibility with legacy systems also provides a seamless upgrade path, allowing plants to maintain their investment while extending the operational life of their control infrastructure.

Ultimately, deploying this module offers peace of mind through a dependable solution that stabilizes communication pathways, protects critical control loops, and supports high availability setups. Whether used in continuous process plants or complex machinery environments, the ABB FPR3203526R1002A empowers engineers with a stable, high-reliability interface that is essential for industrial automation success.

Typical Use Cases

The ABB FPR3203526R1002A is widely used in process control environments demanding uninterrupted signal flow and deterministic timing. It finds strong application in power plants, where system reliability and quick fault recovery in boiler and turbine control sub-systems are vital. The module’s proven compatibility with ABB legacy racks makes it a go-to choice for brownfield projects and plant life-extension programs minimizing downtime impacts.

In the oil & gas industry, the module supports critical communications in gas treatment skid and compressor station automation, where precise control and fast data cycles are necessary to uphold safety and efficiency standards. Chemical processing plants also rely on the ABB FPR3203526R1002A for stable communication between control systems and field devices, helping manage complex reactor trains and utility units effectively under harsh conditions.

Metals and mining facilities benefit from using this module to coordinate auxiliary equipment controls with main process systems, ensuring continuous uptime in furnace operations and rolling mill processes. Its ability to work seamlessly in retrofitted legacy systems highlights its value in industries that prioritize high reliability and backward compatibility without sacrificing performance.

Compatible or Alternative Products

ABB CSA463AE (HIEE400103R0001) – Controller/communication module for ABB legacy DCS backplanes, offering similar system bus interface capabilities.

ABB UAC096 AE01 (HIEE300794R0001) – Direct replacement control module for Advant Master systems, used to stabilize AC400-series networks.

ABB CI854AK01 (3BSE030220R1) – PROFIBUS DP interface module for AC 800M controllers, ideal for robust network communication.

ABB SD812F (3BDH000014R1) – System power supply unit supporting ABB Freelance and AC 800F control stations.

ABB 520PSD01 – Power distribution module designed to stabilize backplane power in process automation environments.

GE IC200GBI001 – VersaMax Genius Bus Interface providing reliable remote I/O for legacy and mixed automation networks.

ABB REF615 HBFFAEAGNBA1ANB1XD – Medium-voltage feeder protection and control device suitable for power distribution.

Setup Notes & Maintenance Insights

Before installing the ABB FPR3203526R1002A, verify that the backplane and rack system are compatible with ABB legacy DCS family standards and that the slot intended for the module matches the Eurocard form factor with the correct keying. Confirm power supply specifications around 24 V DC from the backplane power distribution to ensure stable power input without voltage drops or electrical noise.

Ensure adequate cabinet ventilation is maintained to keep ambient temperatures within the module’s operating range of 0 to +55 °C, preventing thermal stress that could reduce module lifespan. Firmware and configuration settings tied to the parent control system should be validated for compatibility with this module version, especially if used as a replacement in brownfield retrofit scenarios.

Ongoing maintenance involves routine inspection of status LEDs on the module’s front panel to quickly identify communication or hardware anomalies. Connector reliability must be checked periodically to ensure secure mechanical and electrical contacts, and regular function tests during scheduled plant shutdowns help prevent unexpected failures, supporting a proactive maintenance regime that minimizes unplanned downtime.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626