Description

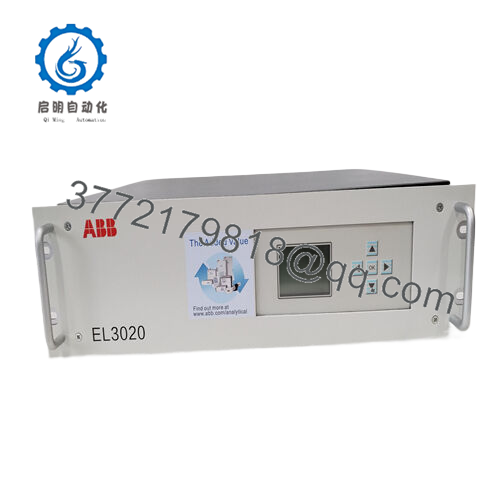

Product Model: EL3020

Product Brand: ABB

Product Series: EasyLine

Product Features:

- Continuous gas analyzer with Uras26 infrared photometer for measuring up to five components (e.g., CO, CO2, NO, SO2, O2) with high accuracy.

- Supports Modbus RTU/TCP and analog outputs (4-20 mA) for seamless integration into DCS and SCADA systems.

- Compact, IP54-rated enclosure suitable for harsh industrial environments, operating from 0°C to 50°C.

- Features self-diagnostics, automatic calibration, and low maintenance for reliable emission monitoring and process control.

The acrid tang of sulfur hangs heavy in the stack of a coal-fired power plant in Poland’s industrial belt, where scrubbers and burners hum under the weight of megawatt demands, and a missed emission spike could trigger fines or forced outages. In this gritty crucible, where every molecule matters for compliance, the EL3020 from ABB stands as a vigilant sentinel. This EasyLine continuous gas analyzer doesn’t just measure—it scrutinizes, detecting trace gases like CO, NO, or SO2 with ppm precision, feeding real-time data to keep plants within regulatory rails. I recall a winter audit in a similar Silesian facility, where a flue gas anomaly threatened a permit violation; the EL3020’s Uras26 module caught a 10 ppm CO2 drift in minutes, guiding a burner tweak that kept the stack clean and the regulators at bay.

Emission monitoring and process control applications, from cement kilns in India’s Rajasthan to petrochemical flares in Texas’ Gulf Coast, hinge on analyzers like the EL3020 for their blend of ruggedness and resolution. Picture a cement preheater tower, where clinker burns at 1,450°C; fluctuating O2 levels could choke efficiency or spike NOx, but this unit’s multi-component capability tracks five gases simultaneously, with ±0.5% accuracy across 0-500 ppm ranges. The challenges? Dust-laden flues that clog sensors or temperature swings that skew readings; its heated sample lines and IP54 housing fend off particulates and maintain stability, even in 95% RH stacks. Operators, huddled over laptops in dusty control shacks, often praise its auto-calibration during a Mexican refinery turnaround, which kept SO2 readings true without manual intervention, slashing downtime.

Extend to waste incinerators in Germany’s Rhine Valley, where dioxin regs demand tight NO and CO monitoring. The EL3020 shines, its Magnos206 oxygen sensor pairing with the Uras26 to deliver cross-stack data via Modbus to SCADA, enabling real-time combustion tweaks that cut emissions by 5%. Field stories from a Düsseldorf burner recount it weathering a 48-hour power flicker, its non-volatile memory holding calibration curves to resume without recal. Or consider biogas plants in Denmark’s windy fields, where methane purity drives revenue; this analyzer’s fast response—under 5 seconds for T90—flags CO2 impurities, ensuring gas grid compliance. In a Jutland digester I visited, it integrated with an 800xA DCS, piping data to optimize aeration without a hitch.

What hooks process engineers to this gas analyzer? It’s the no-nonsense precision that scales with the stakes. In oil sands upgraders in Canada’s Alberta, where hydrogen sulfide lurks in sour gas streams, the EL3020’s low drift (±1% monthly) and self-diagnostics ensure H2S stays below 10 ppm, protecting catalysts and workers alike. Field notes from a Fort McMurray site highlight its Modbus TCP link, which fed live trends to a remote office, cutting site visits by 20%. Across power, cement, and biogas, the EL3020 turns gas chaos into clarity, the analyzer that doesn’t just measure but masters the molecular mix. It’s the quiet backbone of compliance and control, proving ABB’s EasyLine pedigree in plants where emissions are the line between profit and penalty.

- EL3020

- EL3020

Within ABB’s EasyLine ecosystem, the EL3020 reigns as a compact champion, a continuous gas analyzer blending Uras26 infrared and Magnos206 paramagnetic sensors to monitor stack or process gases with lab-grade fidelity. At its core, it’s a microprocessor-driven system with a 32-bit CPU, processing signals from up to five gas channels—think of it as the plant’s chemical nose, sniffing out CO, CO2, NO, SO2, or O2 with ppm sensitivity. Its niche? Wall-mounted in analyzer shelters or control rooms, wired to sample probes via heated lines, interfacing with DCS via 4-20 mA or Modbus RTU/TCP for seamless data flow.

Integration is intuitive: supports Profibus DP and Ethernet alongside analog outputs, with a 7-segment LCD for local setup. I’ve installed it in a hybrid retrofit at a Thai petrochemical plant, where it linked legacy PLCs to an 800xA backbone, delivering 2-second updates on flare gas composition. In a typical stack setup, the EL3020 might pair with a gas conditioner to dry samples, its Uras26 measuring CO at 0-100 ppm while Magnos206 tracks O2 to 25 vol%, with auto-calibration every 24 hours. ABB’s AO2000 software configures it via drag-drop menus, setting alarm thresholds or zero spans—often trimming setup from days to hours in multi-gas sites.

Its prowess peaks in precision and persistence: drift below 1% monthly, with T90 response under 5 seconds for dynamic processes. Scalability? Stack multiple units for complex streams, sharing Modbus buses for centralized logging. A German incinerator I tuned used two EL3020s to monitor dual stacks, their cross-sensitivity compensation ensuring NO readings weren’t skewed by SO2. The analyzer adapts effortlessly—not a prima donna, but the pragmatic pro that aligns gas insights with operational imperatives, ensuring compliance without complexity.

Peering into the EL3020’s specs unveils a masterclass in measurement: a 32-bit processor with 256 MB flash, crunching 12-bit ADC signals for 0.1 ppm resolution on CO and 0.01 vol% on O2. Accuracy? ±0.5% of span, with linearity under 1% FS per EN 15267-3. Benefits blaze: in a Polish power station, it optimized combustion, cutting coal use by 2% via precise O2 control. Design perks—a 300×400 mm IP54 enclosure, with quick-release fittings for probe swaps. Resilience radiates: MTBF over 100,000 hours, with self-diagnostics flagging filter clogs. Field gems: Modbus TCP for remote access, and a 24 V DC option for UPS backup. Temp range 0-50°C, 95% RH—proven in humid stacks where mists test seals. Nuances? Auto-ranging for low/high spans, and 10W draw for lean power. The EL3020 enchants with exactitude—metrics manifesting cleaner stacks, crisper controls, and the calm of compliant cycles.

| Specification | Details |

|---|---|

| Measured Components | Up to 5 (e.g., CO, CO2, NO, SO2, O2) |

| Detector Types | Uras26 (IR), Magnos206 (O2) |

| Range | 0-100 ppm (CO, NO, SO2), 0-25 vol% (O2) |

| Accuracy | ±0.5% of span |

| Response Time | T90 < 5 s |

| Outputs | 4-20 mA, Modbus RTU/TCP, Profibus DP |

| Power Supply | 100-240 V AC or 24 V DC |

| Operating Temperature | 0°C to 50°C |

| Enclosure Rating | IP54 |

| Dimensions (W x H x D) | 300 x 400 x 200 mm |

| Weight | 12 kg |

| Certifications | EN 15267-3, CE, TÜV |

Installing the EL3020 into your process chain is more calibration than chaos—methodical moves ensuring molecular mastery. Mount the unit—wall or rack, away from vibrations—with four M6 bolts at 2 Nm; ensure probe lines are heated to 180°C to avoid condensation. Wiring weave: 4-20 mA to screw terminals, Modbus to RJ45—shield signal cables, as I’ve chased ghost readings from ungrounded loops in a smoky stack shed once too often. Startup sequence: power on, then run auto-cal; LCD shows ready in 15 minutes, sniffing the stream.

ABB’s AO2000 software simplifies setup—Ethernet link to load methods, or clone configs via SD card for fleet uniformity. A tip from a dusty Dubai cement kiln: bench-test the probe with calibration gas to set zero/span before live flow, dodging drift. Maintenance? Clean filters monthly, as dust chokes them; recalibrate quarterly for ppm precision. In corrosive stacks, add purge air to probes. Firmware? Update via USB in 20 minutes—verify checksums, always. A tense tie-in at a Texas flare: auto-cal held true, syncing in 10 minutes. The EL3020 rewards precision, delivering decades of dependable detection with the grace of a tuned sensor.

EasyLine enthusiasts eyeing kin find ABB’s analyzer array ample—each aimed at an angle:

- EL3040: Explosion-proof cousin for Zone 1, unlike the EL3020’s general-purpose grit.

- EL3060: Larger sibling with Caldos27 for thermal conductivity, beyond the EL3020’s IR/O2 focus.

- AO2020: Modular predecessor, for custom configs where the EL3020 compacts.

- EL6010: Portable peer for spot checks, unlike the EL3020’s fixed flow.

- Fidas24: FID-based cousin for hydrocarbons, over the EL3020’s inorganic edge.

- Magnos206: Standalone O2 module, narrowing where the EL3020 multi-measures.

- Uras26: IR-only kin, for single-gas needs unlike the EL3020’s broad band.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626