Description

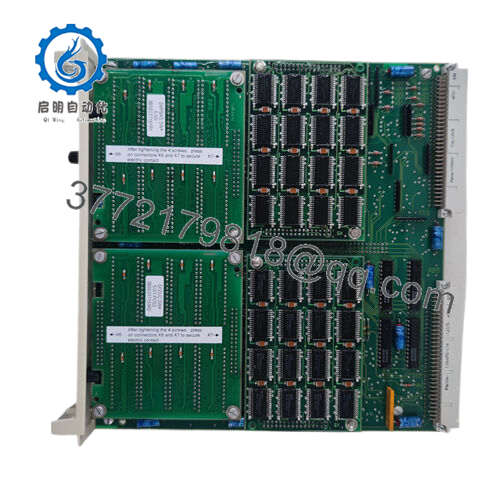

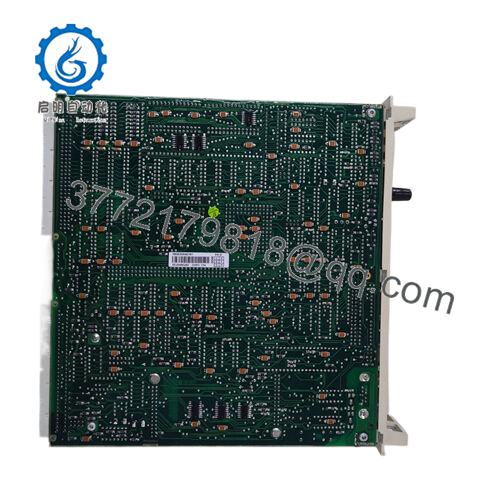

In the realm of industrial automation, where distributed control systems demand unflinching computational power to orchestrate complex sequences, the absence of a robust central processor can unravel even the most meticulously planned setups. Imagine a manufacturing line where real-time data processing lags, leading to desynchronized actuators, overlooked fault diagnostics, or cascading failures in safety interlocks—issues that not only erode throughput but also expose operations to costly regulatory scrutiny in sectors like power generation or chemical processing. This is the crux of the challenge the ABB DSPC174 3BSE005461R1 addresses as a high-performance processor board, engineered to deliver the brains behind seamless process control without the vulnerabilities of outdated hardware.

Engineers tackling expansions in legacy DCS environments often grapple with modules that falter under high data throughput or fail to integrate smoothly with field I/O, resulting in fragmented system architecture and prolonged commissioning times. The ABB DSPC174 3BSE005461R1 becomes indispensable in these scenarios, providing the core processing muscle for ABB’s S800 series, where it handles intensive logic execution, motion control, and communication protocols to maintain signal reliability across distributed nodes. In high-reliability applications, such as renewable energy grids or water treatment plants, it ensures that control loops respond instantaneously to variables like flow rates or voltage fluctuations, preventing the kind of instability that could trigger emergency shutdowns. Without a processor like this, teams waste cycles on ad-hoc fixes rather than advancing toward predictive maintenance through integrated diagnostics.

Drawing from the evolution of industrial automation, where IIoT connectivity amplifies the need for scalable computing, the ABB DSPC174 3BSE005461R1 stands out by embedding redundancy options and fault-tolerant design, allowing hot-swapping in live systems to uphold uptime in 24/7 operations. It’s particularly vital during migrations from older Freelance or AC 800M platforms, where maintaining backward compatibility while boosting performance directly correlates with reduced engineering overhead and enhanced safety compliance. This processor isn’t merely a component; it’s the linchpin that transforms reactive troubleshooting into proactive optimization, empowering your automation ecosystem to scale with evolving demands like edge analytics or multi-protocol interfacing.

| Specification | Details |

|---|---|

| Model Number | 3BSE005461R1 |

| Brand | ABB |

| Type | Processor Board |

| Input Voltage | 24 V DC |

| Operating Temp Range | -40°C to +85°C |

| Mounting Style | DIN Rail (S800 Backplane) |

| Dimensions | 120 x 50 x 110 mm |

| Weight | 0.4 kg |

| Interface/Bus | PROFIBUS DP, ModuleBus |

| Compliance | CE, RoHS, UL, DNV |

| Supported Protocols | Modbus, PROFIBUS, Ethernet |

| Typical Power Draw | 8 W |

DSPC174 3BSE005461R1

DSPC174 3BSE005461R1

The ABB DSPC174 3BSE005461R1 slots into the heart of your automation stack as the primary execution engine, taking raw inputs from field devices via the ModuleBus and churning them into actionable control commands for outputs like valves or drives. In an S800 I/O architecture, it pairs with termination units and communication modules to form a cohesive layer between the physical process and higher-level SCADA or DCS platforms, processing up to thousands of I/O points with sub-millisecond scan times. This positioning—typically mounted in a central rack—facilitates direct ties to ABB’s 800xA system, where it offloads heavy lifting like PID algorithms or sequence logic, freeing the main controller for strategic oversight.

Integration feels intuitive rather than imposed: boot it up, and it auto-detects connected modules, supporting diagnostics that stream event logs over Ethernet for remote analysis. For redundancy, configure dual ABB DSPC174 3BSE005461R1 units in a duplex setup, where failover switches in under 50ms to keep loops intact during maintenance. It embraces protocols like Modbus for legacy tie-ins or PROFIBUS for high-speed fieldbus networks, making it a versatile hub in hybrid environments. Upstream, it interfaces with HMIs for operator tweaks; downstream, it dispatches precise signals to distributed I/O, all while monitoring health metrics to preempt issues like thermal overloads. In essence, this board bridges the gap between edge sensing and cloud-level insights, enabling modular growth without overhauling your backplane—ideal for phased upgrades where minimizing disruptions is paramount.

Opting for the ABB DSPC174 3BSE005461R1 equips your system with processing prowess that turns potential bottlenecks into streamlined efficiency, particularly in scenarios demanding relentless data crunching without compromising on precision. In daily operations, this means your control sequences execute flawlessly, adapting to process variances like load shifts in a turbine without introducing latency that could skew outputs and inflate energy costs. The built-in fault tolerance, for instance, ensures that a single anomaly doesn’t propagate, allowing uninterrupted runs that safeguard against the productivity dips common in less robust setups—ultimately translating to fewer unplanned stops and a sharper focus on yield optimization.

This processor’s design ethos emphasizes endurance in the face of adversity, with wide thermal tolerance that maintains clock speeds during ambient spikes, reducing the engineering overhead tied to custom cooling solutions. Maintenance teams appreciate how its self-diagnostics feed into centralized tools, highlighting degradation trends before they manifest as failures, which cuts diagnostic time and extends overall system longevity. Engineered for the long haul, it fosters performance consistency that aligns with lean manufacturing goals, where every cycle saved compounds into substantial savings. Moreover, its plug-and-play affinity with S800 peripherals streamlines expansions, letting you layer in new sensors or actuators without reconfiguring core logic— a quiet advantage that keeps your automation agile amid shifting production mandates.

Beyond these operational edges, the ABB DSPC174 3BSE005461R1 bolsters strategic resilience, supporting firmware updates over the air to incorporate emerging protocols, ensuring your investment evolves with industry standards rather than obsolescing prematurely. This forward-looking integration eases the burden of compliance audits in regulated fields, as logged events provide traceable proof of reliable operation. In short, it’s a selection that delivers not just raw compute power, but the operational poise to handle complexity with minimal intervention, empowering engineers to innovate rather than iterate on fixes.

Within power generation facilities, the ABB DSPC174 3BSE005461R1 anchors excitation controls for synchronous generators, processing feedback loops to regulate voltage amid fluctuating loads and ensuring critical system uptime in environments battered by electromagnetic noise and extreme temperatures. Its rapid scan rates handle fast data cycles essential for grid stability, preventing blackouts in renewable integrations like wind farms.

In chemical processing plants, deploy the ABB DSPC174 3BSE005461R1 for sequence management in batch reactors, where it orchestrates valve timings and interlocks under corrosive conditions, upholding high reliability for continuous operations that demand zero-tolerance for process deviations. This setup shines in maintaining precise pH or temperature profiles, minimizing waste in high-stakes production.

For transportation infrastructure, such as rail signaling systems, the ABB DSPC174 3BSE005461R1 processes sensor data for automated switches and barriers, thriving in vibration-heavy zones to support fast-response safety protocols and seamless integration with SCADA for real-time monitoring in process control environments.

DSPC170 3BSE005460R1 – Entry-level processor for lighter I/O loads in compact DCS setups. DSPC172 3BSE005462R1 – Mid-range variant with enhanced memory for moderate data-intensive applications. PM866K01 3BSE050198R1 – High-end AC 800M controller for advanced redundancy in large-scale systems. CI854A 3BSE030221R1 – Compatible PROFIBUS module to extend fieldbus connectivity. DSSC180 3BSE013207R1 – Analog I/O companion for balanced signal processing in S800 racks. PM825 3BSE010796R1 – Alternative S800 processor with integrated Ethernet for networked expansions. DSPC175 3BSE005463R1 – Upgraded model offering higher clock speeds for motion control demands.

When preparing to integrate the ABB DSPC174 3BSE005461R1 into your backplane, start by confirming firmware alignment with your I/O processor—download the matching version from ABB’s resource library to sidestep compatibility glitches during initial power-up. Assess slot availability in the S800 rack, factoring in heat dissipation; with its modest draw, it pairs well with adjacent modules, but verify total rack airflow exceeds 50 CFM to stay within thermal bounds. Bus termination is key—ensure PROFIBUS segments are properly ended to avoid reflection errors that could corrupt scan cycles. A pre-install bench test with a subset of your I/O mimics real conditions, catching wiring anomalies early.

Ongoing upkeep keeps things straightforward and proactive. Monthly, pull diagnostic reports via the engineering station to review CPU utilization and error counters; spikes might indicate loop overloads, resolvable by redistributing tasks. Biannually, reseat edge connectors and clean dust from vents with compressed air—neglect here accelerates thermal wear in dusty locales. For SIL-compliant installs, schedule proof tests aligning with your interval, simulating faults to validate failover. These steps, woven into your PM routine, ensure the module sustains peak efficiency without demanding specialized downtime, giving your team visibility into health metrics that inform upgrades before issues arise.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626