Description

In modern industrial automation, accurate measurement of position, speed, and frequency is indispensable for precise control and monitoring of machinery and processes. The ABB DSDP170K02 3BSE019925R1 pulse encoder input module serves this critical role in sectors such as manufacturing, energy production, material handling, and process industries. It is primarily implemented within control systems where pulse signals generated by rotary or linear encoders need to be reliably interpreted. These signals translate physical motion into digital data, enabling real-time feedback for motion control applications in conveyor lines, robotic arms, and automated assembly processes.

Industries including automotive manufacturing, packaging, paper mills, and power plants rely on this module to convert high-frequency pulses into meaningful control inputs that drive precise speed regulation and positioning tasks. The ABB DSDP170K02 3BSE019925R1 is widely used in complex distributed control environments—especially ABB’s Advant Controller series—where robust, noise-resistant input processing is vital. This module tackles challenges such as fluctuating signal quality and high pulse rates up to 2.5 MHz, ensuring continuous, accurate monitoring despite harsh electromagnetic interference common in industrial settings. Its ability to handle multiple count resolutions makes it adaptable to a broad range of encoder types and application requirements.

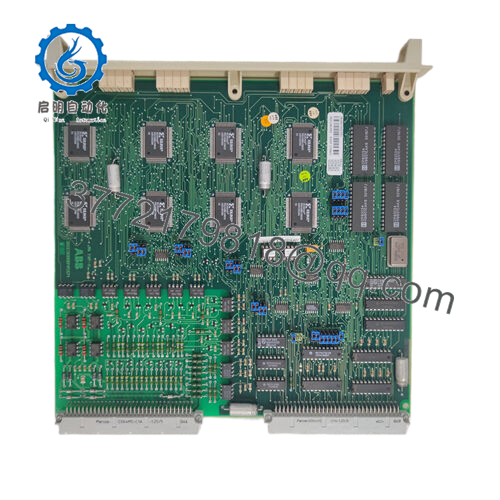

Product Introduction & Positioning

The ABB DSDP170K02 3BSE019925R1 is a specialized I/O module functioning as a pulse encoder input interface within ABB’s Advant Controller 400 series and related DCS platforms. It is engineered to process up to four channels of pulse inputs, converting signals from incremental encoders into actionable data for control and measurement. This module fits into the larger architecture of advanced process and motion control systems, interfacing directly with control units that manage machinery movement and positioning.

By integrating seamlessly into ABB’s established digital control framework, the ABB DSDP170K02 3BSE019925R1 provides engineers critical feedback channels for closed-loop control strategies, enhancing system responsiveness and accuracy. Its design caters to flagship ABB automation platforms, positioning it as a go-to solution for pulse signal acquisition in environments requiring dependable, real-time speed and position measurement. The module’s compatibility with various pulse resolutions and input voltage ranges provides flexibility for system integrators addressing diverse industrial encoder outputs.

Key Technical Features & Functional Benefits

The ABB DSDP170K02 3BSE019925R1 excels through its robust handling of pulse inputs at frequencies up to 2.5 MHz, allowing it to support very high-speed machinery and rapid motion feedback requirements. Its capacity to work across multiple resolution settings—1x, 2x, 4x, and 8x count—means it can adapt to different encoder configurations and improve signal interpretation accuracy for diverse industrial applications. Supporting input voltage ranges between 5 to 24 V DC, it accommodates a wide variety of encoder types, maintaining signal integrity even in challenging electrical environments.

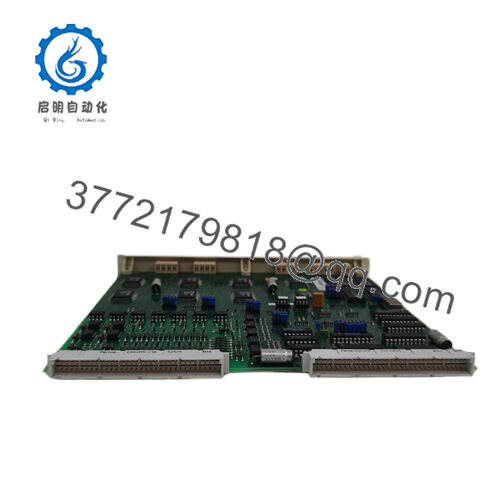

Engineered for industrial durability, the module operates reliably within a broad temperature range from -40°C to +70°C, making it suitable for extreme environments often found in manufacturing plants, outdoor installations, or heavy machinery. Its compact dimensions (approximately 328.5 mm by 72 mm by 238.5 mm) and weight of about 1 kg enable easy integration into existing control racks without excessive footprint.

Designed for straightforward installation on ABB’s I/O subracks, the ABB DSDP170K02 3BSE019925R1 supports smooth system expansion or replacement workflows. Long-term reliability is bolstered by high-quality components that resist electrical noise and provide stable signal acquisition, reducing system errors or downtime. By delivering precise and stable pulse input readings, the module helps drive optimal process control quality and equipment performance.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | DSDP170K02 3BSE019925R1 |

| Brand | ABB |

| Product Type | Pulse Encoder Input Module |

| Number of Channels | 4 |

| Input Voltage Range | 5 to 24 V DC |

| Maximum Pulse Frequency | Up to 2.5 MHz |

| Supported Resolution | 1x, 2x, 4x, 8x count |

| Operating Temperature | -40°C to +70°C |

| Dimensions (D x H x W) | 328.5 mm x 72 mm x 238.5 mm |

| Weight | 1 kg |

| Mounting Type | DIN rail / I/O subrack |

| Interface | Pulse Input |

| Certifications | RoHS Exempt* |

DSDP170K02 3BSE019925R1

DSDP170K02 3BSE019925R1

Related Modules or Compatible Units

ABB DSRF197K01 – An I/O subrack module compatible with the DSDP170K02 for encoder signal processing.

ABB DSTX170 3BSE019926R1 – Connection unit that complements pulse input modules in ABB control systems.

ABB DSDP170K01 3BSE019924R1 – Similar pulse encoder input module with slight variation in features or firmware.

ABB 3BSE020034R1 – Digital output module often paired in control racks with the DSDP170K02 input module.

ABB 3BSE019927R1 – Analog input module used alongside pulse inputs for hybrid signal processing needs.

ABB DSSP0104 – Signal conversion unit compatible with the Advant controller series.

ABB Advant Controller 400 – Control platform designed to work natively with the DSDP170K02 pulse input module.

Installation Notes & Maintenance Best Practices

Before installation of the ABB DSDP170K02 3BSE019925R1, careful planning of the control cabinet layout is essential, ensuring ample space for mounting the module on standardized I/O subracks or DIN rails. Proper grounding and shielding of encoder cables will preserve signal integrity and protect the module from electromagnetic interference, a common challenge in industrial settings. Verify that encoder wiring matches the input voltage specifications (5 to 24 V DC) and pulse type supported by the module to prevent damage and signal errors. Clear labeling and organized cabling during installation help simplify future troubleshooting.

Maintenance should include regular visual inspection for signs of connector wear, corrosion, or physical damage. Pulse input signals may degrade over time due to cable aging or environmental factors; thus, periodic signal diagnostics should be performed using system tools to verify pulse accuracy and consistency. Firmware updates or configuration audits for the wider control system can help keep the module and associated controllers synchronized with evolving operational requirements. Keeping spare input modules and backup cables accessible minimizes production impact during upgrades or repairs.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626