Description

In the thrum of a steel rolling mill in Pennsylvania, where conveyor speeds must match mill torque to avoid strip tears that scrap tons of metal in seconds, pulse counter boards like the ABB DSDP140B capture high-frequency encoder signals from shaft sensors, feeding precise position data to drives for seamless synchronization. Fast-forward to a pharmaceutical packaging line in Ireland, bottling injectables under GMP scrutiny—the ABB DSDP140B tallies cap placements from optical gates, triggering rejects if counts drift, ensuring zero contamination risks amid sterile airflows. Or consider a wind turbine assembly yard in Denmark, erecting blades longer than blue whales; here, the ABB DSDP140B tracks bolt torques via pulse generators, halting cranes if thresholds slip to prevent costly rework in blustery yards. These boards anchor operations where timing isn’t just efficiency—it’s safety, from hydroelectric dams in Brazil metering turbine revolutions to offset grid surges to automotive test benches in Michigan logging wheel rotations for brake validation.

Deeper in the mix, wastewater lift stations in arid UAE use the ABB DSDP140B to monitor pump strokes against flow pulses, averting overflows that could flood treatment basins during flash monsoons. In food extrusion plants in Thailand, it counts extrudate segments for portioning, dodging underfills that spike recalls in global supply chains. Used in industrial automation for motion and process tracking, this module wrestles with hurdles like signal jitter from long cable hauls or EMI bursts near arc welders in shipyards. Applicable in control systems like ABB’s Advant OCS or S800 I/O extensions, the ABB DSDP140B enables granular logging in DCS setups, letting integrators retrofit encoders without full rewires. By fusing pulse inputs with discrete I/O, it sharpens diagnostics in renewables syncing inverter pulses or mining hoists tallying ore skips, flipping raw ticks into predictive intelligence that keeps yields climbing in sectors where fractions of a percent define profits.

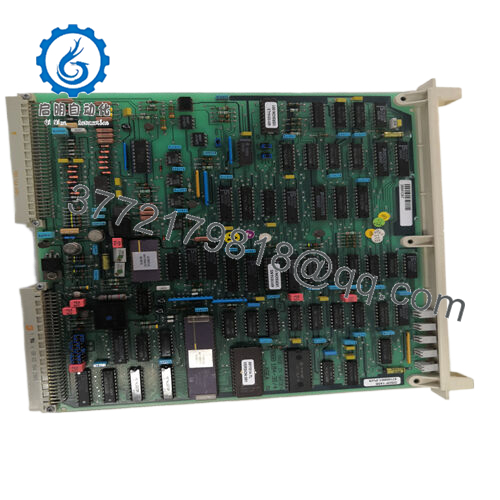

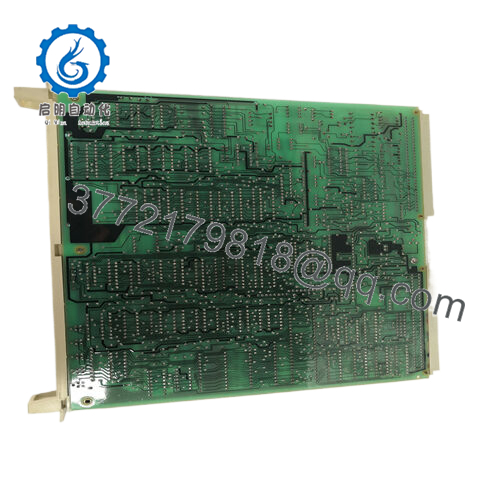

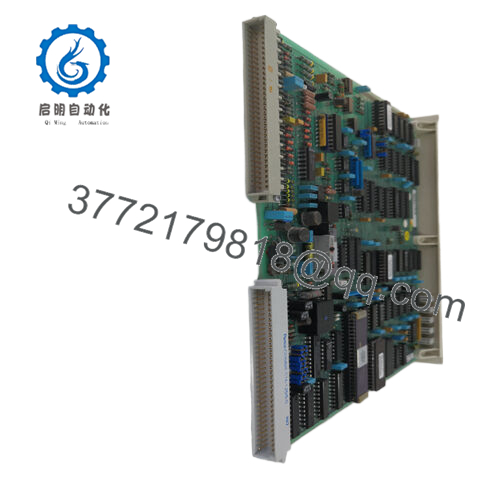

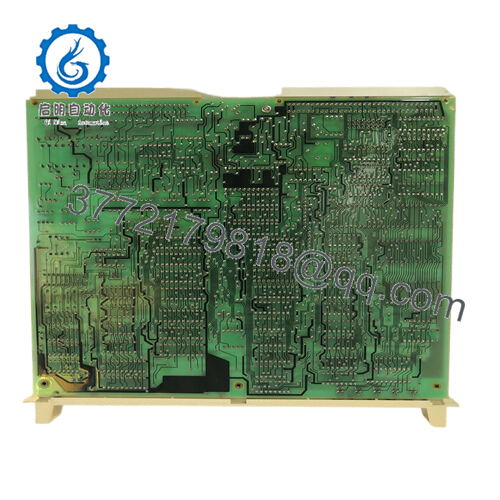

The ABB DSDP140B is a pulse counter board tailored for ABB’s legacy S100 and Advant OCS I/O architectures, serving as a specialized interface for high-speed event capture in distributed control networks. It processes pulses from generators or encoders while handling auxiliary digital inputs, outputs, and analog feedback, mounting via ribbon cables to termination units for field-to-logic bridging. Within ABB’s modular I/O ecosystem, it extends processor modules like the PM864, supporting up to 80 kHz inputs across three channels to track velocities or positions in real-time loops. Operators rely on it for embedding in PLC hybrids, where it decodes quadrature signals for direction-aware counting, all without taxing main CPU cycles.

- DSDP140B

- DSDP140B

What carves out the ABB DSDP140B‘s niche is its knack for breathing life into older systems during phased modernizations—pair it with Ethernet gateways for SCADA uplinks, and it slots into 800xA overhauls without forklift upgrades. Technicians dig the onboard resolution for analog trims, dialing outputs to 11 bits for fine servo tweaks in pick-and-place robots. In fault-resilient frames, it daisy-chains for redundancy, mirroring counts to dodge data blackouts in safety-rated zones. Its lean profile and jumper-configurable modes make it a retrofit darling in utilities metering substation pulses or breweries timing fermenter agitators, where the ABB DSDP140B quietly elevates granularity without bloating budgets or benches.

Hands-on crews highlight the ABB DSDP140B‘s pulse agility, gobbling 80 kHz inputs with 15 mA sensitivity to snag fleeting edges from resolvers in compressor trains, where missed ticks could imbalance rotors and chew bearings. The trio of counter channels pairs with two DI for gating and four relay DO for alarms, plus a 0-10 V AO for speed references—versatile enough to loop in PID for conveyor pacing. Error resilience pops with opto-isolation on inputs, clamping surges to 24 V DC while debounce filters tame noisy contacts from dusty grinders. Digital signal processing weeds harmonics, holding counts to 0.01% accuracy over cycles, which shines in frequency assays for vibration monitors on gas pipelines.

Hardware grit defines the ABB DSDP140B, with a DIN-rackable chassis of flame-retardant composites shrugging 95% humidity and -20°C chills in subzero paper dryers. Slender at 150x100x50 mm and 0.5 kg, it clips into crowded marshals, drawing 5 V logic from the bus to sip under 2 W passively cooled. It syncs via serial or ModuleBus for S100 drops, and HART overlays let smart encoders pipe diagnostics without extra wires. Built for 100,000+ hour MTBF, its ceramic caps and derated relays endure cyclic hammering in packaging winders, while CE/UL nods clear hazardous nods with barriers.

Endurance seals the ABB DSDP140B‘s legacy, with self-test loops validating quadrature phases offline and thermal guards halting at 70°C to avert latch-ups in sun-scorched solar trackers. Configurable via jumpers or OCS software, it adapts to incremental or absolute modes, easing swaps in evolving fleets. For shops chasing IEC 61508 basics, its deterministic latency under 1 ms turns pulses into certifiable events, making the ABB DSDP140B an enduring pick for where counts compound into control.

| Parameter | Value |

|---|---|

| Model | DSDP140B |

| Brand | ABB |

| Type | Pulse Counter Board |

| Power Supply | 24 V DC (18-30 V range) |

| Operating Temperature | -20°C to +60°C |

| Mounting | DIN rail or rack mount |

| Dimensions | 150 mm width x 100 mm height x 50 mm depth |

| Weight | 0.5 kg |

| Interfaces | 1 pulse input, 2 DI, 4 DO, 1 AO; ribbon cable, ModuleBus |

| Certifications | CE, UL 508, RoHS compliant |

| Cooling | Passive convection |

| Environmental Rating | IP20 (enclosure for harsh use) |

DSDP140A – Predecessor with similar pulse handling but lower 50 kHz max, ideal for legacy S100 retrofits alongside DSDP140B.

DSDP130 57160001-ABX – Streamlined variant with 8 channels, complements DSDP140B in cost-sensitive counting apps like basic metering. DSAI130A 3BSE018292R1 – Analog input module, pairs for hybrid signal fusion in Advant OCS with DSDP140B pulse data. DSDX452 – Basic I/O expander, links via bus for added discrete oversight in expanded DSDP140B setups.

CI570 3BSE001440R1 – Communication interface, enables Profibus connectivity for remote DSDP140B deployments.

DSQC651 – Robot control unit, integrates DSDP140B for encoder feedback in ABB arm applications.

TU810V1 3BSE008580R1 – Termination block, simplifies field wiring for DSDP140B in distributed I/O racks.

Before easing the ABB DSDP140B into a panel, gauge slot gaps at 25 mm for probe access, especially in stacked S100 frames where heat pools low. Clamp ribbon cables with shielded ties, routing away from AC lines to nix capacitive noise, and ground the shield at one end with 4 mm² braid torqued to 1.2 Nm. Prime with a 24 V sweep across DI to confirm wetting, then pulse-test channels at 10 kHz with a function gen to lock quadrature decode—no glitches over 0.1 ms edges. In expansions, sequence addresses low-to-high to skirt bus echoes, and jumper AO for voltage if current loops lag.

Tending the ABB DSDP140B leans on quarterly sweeps: oscilloscope gate pulses for droop under load, and harvest OCS logs for overrun tallies topping 1% to flag encoder wear. Dust relays with canned air in flour mills, and cycle DO dry annually to check <20 mΩ contacts. Firmware nudges via serial need a full dump first—staged in lulls, then validate with a decade box mimicking 4-20 mA. In vibratory crushers, add dampers under mounts and peek solder joints biyearly for cracks. These touches sustain the ABB DSDP140B‘s tick, warding drifts that derail downstream.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626