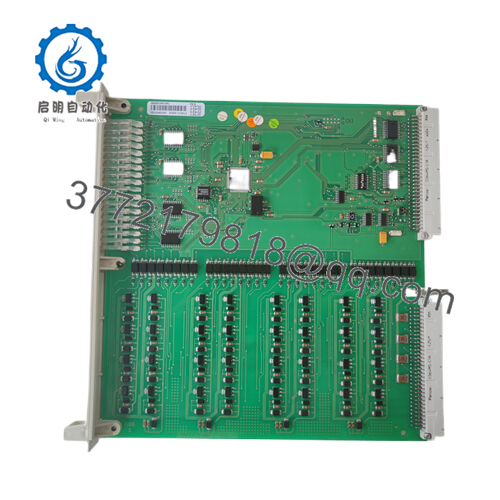

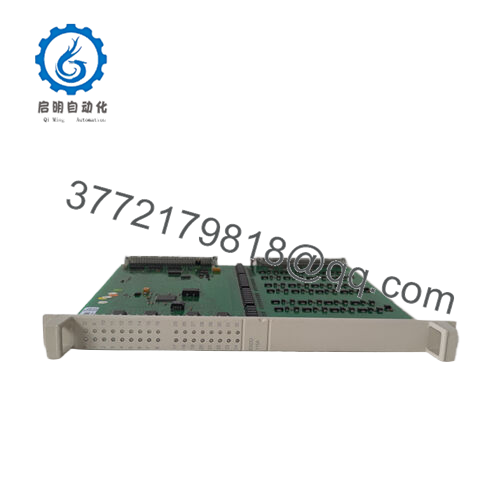

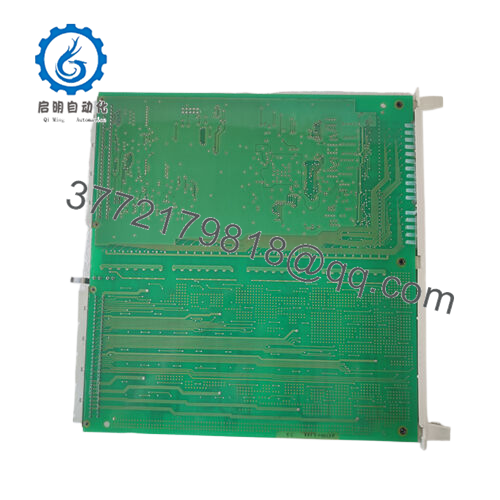

Description

In the fast-paced world of industrial automation, coordinating discrete actuators, solenoids, and indicator lamps often exposes the fragility of output signaling—where a single channel failure can cascade into halted conveyors, stalled pumps, or compromised safety circuits, inflating downtime and repair bills in unforgiving settings. Envision a packaging line where erratic digital commands lead to misaligned seals, or a wastewater plant where unreliable solenoid triggers flood clarifiers, turning routine shifts into crisis management. These pain points underscore the need for a sturdy digital output solution that guarantees crisp, isolated signaling amid electrical noise and heavy inductive loads, and that’s precisely what the ABB DSDO115K12 3BSE019933R1 delivers as a comprehensive digital output kit tailored for high-stakes process control.

Control engineers retrofitting or expanding DCS frameworks regularly contend with modules that buckle under simultaneous switching demands or introduce ground faults in shared bus environments, complicating integration and eroding signal reliability. The ABB DSDO115K12 3BSE019933R1 emerges as a go-to in these contexts, bundling 32 channels of robust 24 VDC output into a ready-to-deploy package that interfaces seamlessly with ABB’s legacy and modern platforms. It’s crucial for applications like batch sequencing in food processing or emergency shutdowns in oil refineries, where each output must fire with precision to sustain operational flow without false trips. Lacking such a kit, you’d face frequent recalibrations or custom shielding hacks, diverting resources from core innovations to mere survival tactics.

Within the broader tapestry of industrial automation, as facilities push toward hybrid edge-cloud architectures, the demand surges for I/O kits that embed diagnostics and protection without bloating cabinet footprints. The ABB DSDO115K12 3BSE019933R1 excels by incorporating relay-based isolation per channel, buffering against back-EMF from motors or valves to preserve system integrity in vibration-prone zones. This kit isn’t a band-aid; it’s the foundational layer that enables predictive fault handling, letting your team anticipate overloads via embedded status feedback rather than chasing intermittent glitches. In compliance-heavy arenas like pharmaceuticals or utilities, where audit trails for output events are mandatory, it fortifies high reliability, aligning your setup with standards like SIL 2 while streamlining the path to scalable expansions.

DSDO115K12 3BSE019933R1

DSDO115K12 3BSE019933R1

| Specification | Details |

|---|---|

| Model Number | 3BSE019933R1 |

| Brand | ABB |

| Type | Digital Output Kit |

| Input Voltage | 24 V DC |

| Operating Temp Range | -25°C to +70°C |

| Mounting Style | DIN Rail (S800 Backplane) |

| Dimensions | 120 x 50 x 110 mm |

| Weight | 0.35 kg |

| Interface/Bus | ModuleBus |

| Compliance | CE, RoHS (exempted) |

| Supported Protocols | PROFIBUS DP, Modbus |

| Typical Power Draw | 6 W |

The ABB DSDO115K12 3BSE019933R1 operates at the frontline of your I/O architecture, transforming controller logic into discrete on/off pulses that energize field devices across 32 independent channels, all housed within an S800-compatible backplane for distributed edge processing. It hooks into the ModuleBus for rapid handshakes with upstream processors like the DSPC174, relaying commands to solenoids or relays while feeding back channel states to central diagnostics—think of it as the reliable dispatcher in a bustling control room, ensuring no output gets lost in transit. This kit’s sweet spot lies in its mid-tier positioning: close enough to the process for short cable runs that cut noise, yet modular enough to stack with analog siblings in a unified rack, supporting everything from simple on-off automation to sequenced interlocks.

What makes it click in live systems is the thoughtful interplay: each output sinks up to 150 mA at 24 VDC, with opto-isolation to decouple the bus from field hazards, so a shorted lamp doesn’t fry adjacent lines. Termination options in the kit—screw or spring variants—let you tailor wiring to your enclosure’s vibe, while built-in fusing and LED arrays offer at-a-glance health checks, streamlining remote monitoring via PROFIBUS gateways. For setups craving resilience, it embraces redundant configurations, mirroring outputs across duplex kits to weather hardware swaps without process hiccups. Upstream, it draws boolean sets from PID or ladder logic in your DCS; downstream, it drives diverse loads like pneumatic valves or alarm beacons, all calibrated to 1ms response times for snappy cycle control. In essence, the ABB DSDO115K12 3BSE019933R1 weaves into your stack as a low-friction enabler, bridging legacy MOD 300 ties with 800xA evolutions to keep hybrid fleets humming without forced overhauls.

Selecting the ABB DSDO115K12 3BSE019933R1 arms your operations with output orchestration that prioritizes endurance over ephemera, especially in load-heavy loops where inductive kicks routinely test lesser boards. Day-to-day, this means your sequences unfold with unwavering fidelity—actuators engage on cue without chatter-induced delays, yielding tighter tolerances in assembly lines and slashing rejects from timing slips. The per-channel safeguards, for one, absorb surges that might otherwise demand full-rack isolators, letting your electricians focus on expansions rather than endless fuse hunts, which in turn trims commissioning hours and fosters a culture of reliable uptime.

This kit’s architecture leans into the realities of sustained deployment, with thermal margins that hold steady through ambient flux, minimizing the tweaks needed for seasonal recalibrations in variable climates. Operators gain from the diagnostic transparency, as fault codes pulse to HMIs for quick triage, often resolving to a loose terminal rather than a board swap—easing the maintenance ledger and extending mean time between interventions. Engineered for the unyielding pulse of production, it cultivates performance consistency that dovetails with ESG goals, like energy-efficient switching that curbs idle draw in green-certified plants. Plus, its kit format reduces engineering overhead upfront, bundling the board, base, and fuses to sidestep sourcing snafus, so your project timelines stay on rails.

Layer in the scalability angle, and the ABB DSDO115K12 3BSE019933R1 reveals its strategic depth: firmware flashes adapt it to emerging protocols without hardware churn, preserving value as your DCS matures toward IIoT overlays. This adaptability lightens the load during audits, with logged output histories proving compliance sans manual logs. At bottom, it’s a pivot toward proactive control, where robust signaling unlocks efficiencies that ripple from floor to C-suite, turning potential vulnerabilities into vetted strengths.

In automotive assembly halls, the ABB DSDO115K12 3BSE019933R1 powers robotic grippers and conveyor clutches, delivering 32 crisp pulses for synchronized part feeds in high-speed lines, where fast data cycles and vibration resistance ensure critical system uptime amid relentless 24/7 rhythms. Its isolation wards off EMI from welders, keeping sequences glitch-free for just-in-time precision.

Pulp and paper mills lean on the ABB DSDO115K12 3BSE019933R1 to sequence headbox valves and dryer controls, thriving in steamy, fibrous environs with outputs tuned for inductive steam actuators—vital for maintaining web tension without tears, upholding high reliability in process control environments that brook no fiber loss.

Mining operations deploy the ABB DSDO115K12 3BSE019933R1 for conveyor starters and floodlight relays deep underground, handling dusty, jolt-heavy conditions to trigger safe material flows, with diagnostics ensuring continuous uptime in remote setups where signal fidelity spells the difference between haul and halt.

DSDO115A 3BSE018298R1 – Core board variant without bundled accessories, for custom termination builds. DSDO115K10 3BSE019931R1 – Economy kit with basic fusing for low-load discrete signaling. DSDO115K11 3BSE019932R1 – Enhanced kit adding surge suppressors for motor-heavy applications. DO820 3BSE008412R1 – S800 successor with higher channel density for modern DCS migrations. 57160001-NF – Legacy exchange unit compatible with older Advant OCS frameworks. DSDI115 3BSE019934R1 – Matching digital input kit for balanced rack configurations. DO810 3BSE008508R1 – Compact alternative with 16 channels for space-limited enclosures.

As you gear up to rack the ABB DSDO115K12 3BSE019933R1, verify ModuleBus sync with your processor model—ABB’s compatibility matrix on their portal flags any firmware deltas that could snag enumeration. Probe the backplane slot for prior occupancy ghosts, like bent pins from hasty swaps, and map out load currents to confirm the kit’s 150 mA ceiling won’t overload shared supplies; a spreadsheet tally here prevents post-install brownouts. Allocate breathing room in the enclosure—aim for 50 mm clearance above for convective cooling, especially if stacking with power-hungry neighbors. Pre-wire the termination block on a bench to test continuity, catching crossed pairs before they bite during hot cutover.

In service, vigilance pays modest dividends. Weekly sweeps of the status LEDs catch open fuses or stuck relays—replace with the kit’s spares using a slotted driver at 0.6 Nm torque to avoid stripping threads. Quarterly, cycle all channels under simulated load with a multimeter to baseline response, flagging drifts from cable capacitance; in humid sites, a dielectric grease dab on contacts thwarts oxidation. Tie diagnostics to your CMMS for trend alerts, like cumulative switch counts nearing 100k cycles, prompting proactive refreshes. For hazardous zones, sync inspections with ATEX intervals, using non-sparking tools. This regimen keeps the kit’s pulse strong, embedding reliability checks into workflows without commandeering shifts.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626