Description

What This Product Solves

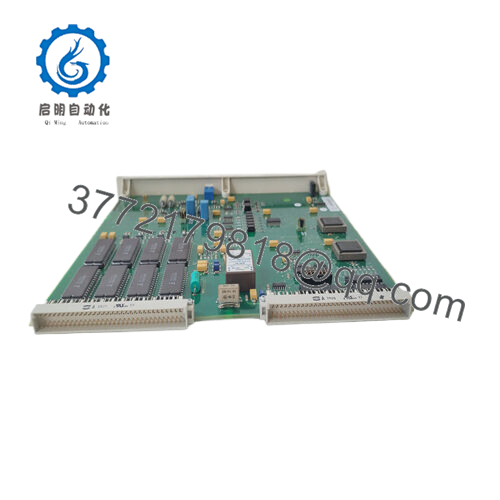

In any process control environment, accurate sensing of process variables is foundational to stable control and safe operation. The ABB DSAI146 addresses the need for high-precision analog input capture across a dense mix of Pt100 sensors and digital signals, while preserving signal integrity in electrically noisy industrial spaces. This module is particularly valuable during plant expansions, retrofits, or greenfield installations where a scalable I/O backbone must support many sensors without overwhelming the controller with jitter, drift, or calibration drift. For engineers, the key benefit is confidence: fewer field errors, clearer diagnostics, and more deterministic feedback to the control loop. With robust channel multiplexing, high-resolution ADCs, and reliable isolation, DSAI146 helps maintain consistent process measurements, enabling tighter control and improved energy efficiency, quality, and safety. In practice, it’s a reliable backbone for industrial automation, process control, and continuous manufacturing environments where 31 Pt100 inputs and associated channels demand trustworthy data. The DSAI146 family is well-suited to multi-zone control schemes, where centralized decision-making hinges on uniform, traceable analog data. This model supports engineers seeking a durable, field-proven analog input solution that minimizes rework and maximizes uptime.

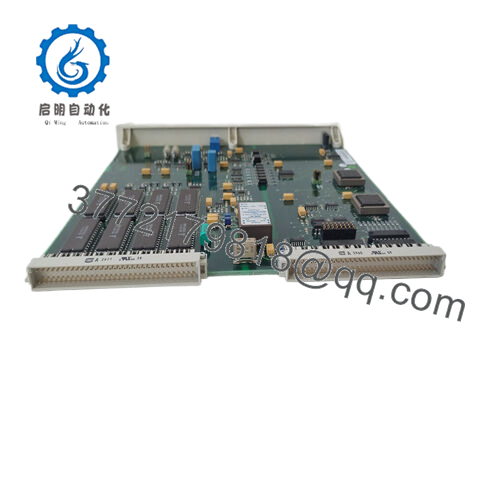

How the Product Works & Fits into a System

The DSAI146 analog input unit slots into an Advant or similar ABB control cabinet as a high-density input module, interfacing field sensors with the central controller. It converts resistance signals from Pt100 sensors and related analog sources into digital values for the PLC or DCS, while preserving signal integrity through isolation and multiplexing. In the automation stack, it sits at the I/O boundary, feeding a backplane or fieldbus interface that connects to the processor, enabling synchronized sampling across channels. It supports diagnostic readouts to help detect sensor faults or wiring issues before they impact process control. Depending on configuration, it can plug into redundant backplanes and leverage ABB’s standard protocols for seamless integration with ABB and third-party control platforms. The model name appears again here as the anchor for compatibility discussions with related analog input modules and expansion options, ensuring engineers can plan scalable I/O growth without mismatches. The DSAI146 thus acts as a reliable conduit for precise temperature sensing and analog data in industrial automation environments.

- DSAI146

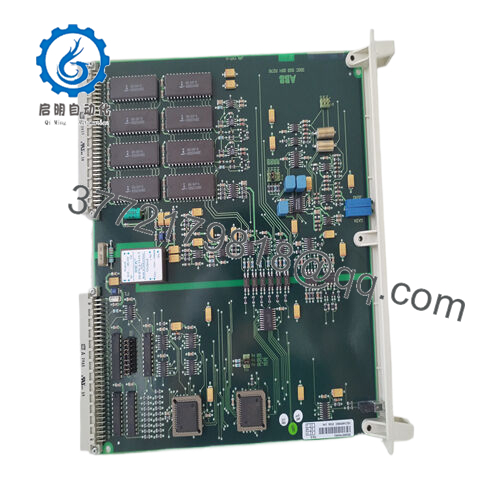

Technical Highlights Summary (Table)

Specification | Details

Model Number | DSAI146

Brand | ABB

Type | Analog Input Unit

Input Channels | 31 Pt100 inputs plus supporting digital channels

Resolution / ADC | 16-bit (typical)

Measurement Range | Pt100 0–200°C (typical, confirm)

Input Wiring | 3-wire Pt100 standard

Isolation | Yes (channel-to-backplane isolation, per standard practice)

Power Supply | 24 V DC (typical), additional rails as required

Operating Temperature | -20°C to +70°C (typical)

Dimensions | 324 mm x 22.5 mm x 234 mm (typical footprint)

Weight | ~0.4 kg

Interface/Bus | Advant backplane, optional fieldbus interfaces (e.g., Profibus, Modbus)

Compliance | CE, RoHS

Supported Protocols | ABB native I/O protocol, Profibus DP, Modbus (RTU/TCP) depending on configuration

Typical Power Draw | [Value to be confirmed by spec sheet]

Real-World Benefits

The DSAI146 is engineered for long-term reliability in demanding industrial spaces, delivering high-precision analog input data with consistent calibration and drift control. Its dense channel count reduces cabinet footprint while maintaining measurement fidelity, which translates to simpler wiring schemes and faster system integration. Reliability in such modules means less frequent recalibration and fewer data-quality concerns that can derail control performance. The diagnostic features help technicians quickly locate faulty sensors or cabling, reducing maintenance overhead and improving uptime. By delivering stable, high-resolution signals to the controller, operators can sustain tighter process control loops, improve product consistency, and lower energy consumption through more optimal setpoints. The combination of precision, reliability, and integration ease makes the DSAI146 a practical choice for plants pursuing lean maintenance strategies and targeting maximum availability of critical sensors.

Typical Use Cases

This module is commonly deployed in process control environments where accurate temperature measurement and analog signaling are essential. In chemical processing, oil and gas refining, and power generation, the 31 Pt100 inputs enable comprehensive temperature profiling and heat management across large facilities, contributing to safe and efficient operation. Manufacturing lines that require lots of temperature sensing for quality control also benefit, as does water treatment where precise sensor feedback informs dosing and flow regulation. The model supports robust data collection in environments with moderate to high electrical noise, ensuring high-quality input data supports continuous operation and predictable control outcomes. Across these contexts, DSAI146 helps facilities meet process control requirements while maintaining high availability and diagnostic visibility for proactive maintenance.

Compatible or Alternative Products

Boldly consider these related models for upgrades or complementary components:

- DSAI146 – Base variant for 31 Pt100 channels with original feature set

- DSAI146A – Updated revision with improved calibration and diagnostics

- DSAI146B – Variant with enhanced digital I/O integration

- DSAI147 – Next-gen with additional channels or expanded protocol support

- DSAI125 – Lower-channel-count predecessor for smaller backplanes

- DSAI148 – Expanded temperature range variant

- DSAI149 – High-accuracy option with tighter drift specs

- DSAI150 – Future-proofed variant with expanded power and inline diagnostics

Setup Notes & Maintenance Insights

Before installation, verify compatibility with the host controller, backplane slot, and any required fieldbus adapters. Confirm the sensor wiring topology for Pt100 channels (3-wire configuration) and ensure the power supply rails meet the module’s requirements. Allow adequate clearance for heat dissipation and verify that the module’s firmware aligns with the controller’s software version to avoid incompatibilities. After mounting, perform a baseline calibration check if applicable and review channel health indicators. Schedule periodic maintenance to inspect signal wiring, verify channel-by-channel measurements against known references, and confirm that diagnostic thresholds stay aligned with process safety limits. Maintain thorough wiring diagrams and keep spare analog input cards handy to minimize downtime during fault isolation or replacements.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626