Description

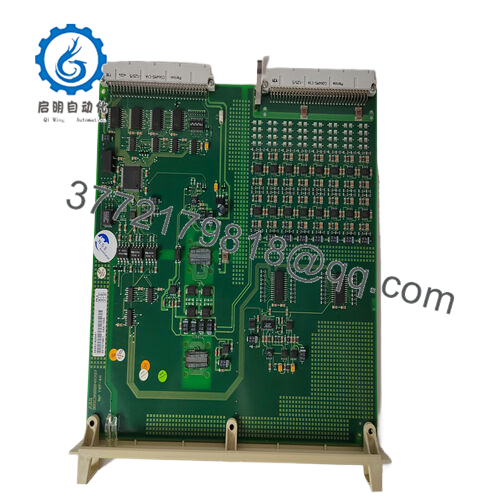

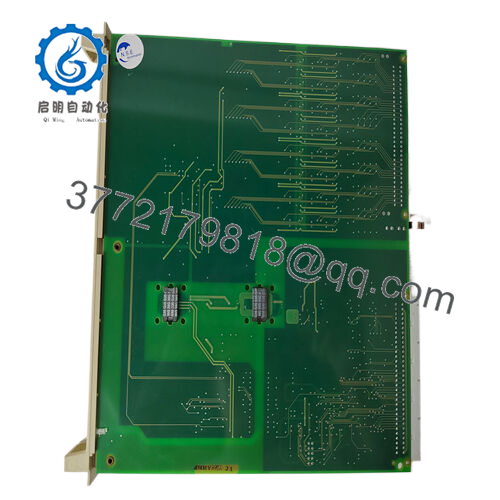

ABB DSAI133A 3BSE018290R1 Product Introduction:

ABB DSAI133A 3BSE018290R1 is a high-performance analog input module designed for seamless integration into ABB’s control system ecosystem, such as the ADVANT OCS controller. As a component of input/output (I/O) architecture, it serves as the interface between real-world analog sensors and digital control systems. With its 32 channels, it is capable of processing a large number of analog signals simultaneously, whether from temperature sensors, pressure sensors, or flow meters.

ABB DSAI133A 3BSE018290R1

In the hierarchical structure of the control system, it is located at the forefront, converting continuous analog values (such as 4-20mA current loops or ± 10V voltage signals) into digital data that can be processed by higher-level controllers. Engineers and integrators value its compatibility with ABB’s control and monitoring software suite, which simplifies system configuration and calibration. Its modular design facilitates installation and replacement, reducing downtime during maintenance or system upgrades. The overall ABB DSAI133A 3BSE018290R1 is a key driving factor in building reliable, efficient, and scalable industrial control systems.

ABB DSAI133A 3BSE018290R1

Technical specifications:

|Model |: ABB DSAI133A 3BSE018290R1

|Brand |: ABB

|Type |: Analog input module (32 channels)

|Power supply |: 24 V DC ± 20%

|Working temperature |: -40 ° C to+70 ° C

|Installation |: Suitable for standard DIN rails (TS 35/7.5 or TS 35/15)

|Size |: 225 millimeters (width) x 22.5 millimeters (height) x 324 millimeters (depth)

|Weight |: 0.29 kilograms

|Input range: | ± 10 V, ± 20 mA

|Resolution |: 16 bits

|Sampling rate |: up to 1 kHz

|Communication Interface |: Ethernet

|Isolation |: 1500V AC

|Certification |: Compliant with relevant industry standards (such as CE, UL, CSA)

Contact Us

Phone:+86 16626708626

WhatsApp/WeChat:+86 16626708626

Email: 3772179818@qq.com

ABB DSAI133A 3BSE018290R1

Main features and advantages:

One of the outstanding features of ABB DSAI133A 3BSE018290R1 is its high-resolution analog-to-digital conversion. With 16 bit resolution, it can even detect the slightest changes in analog signals, providing high accuracy within ± 0.1% of full scale. This precision is crucial for applications where small changes in process parameters may have a significant impact on product quality or system performance.

The hardware design of this module is sturdy and durable, capable of withstanding harsh industrial environments. It has a wide operating temperature range, from -40 ° C to+70 ° C, making it suitable for indoor and outdoor installations even under extreme weather conditions. In addition, it also provides 1500V AC isolation to prevent common surges and interference in industrial environments.

In terms of communication, it has an Ethernet interface that can quickly and reliably transmit data to the connected control system. This allows for real-time monitoring and control, which is crucial for maintaining process stability. ABB DSAI133A 3BSE018290R1 also supports various input types, including ± 10 V and ± 20 mA, providing flexibility for different sensor and transducer settings. Its high sampling rate of 1kHz ensures that it can quickly capture and process constantly changing analog signals, making it highly suitable for dynamic industrial processes.

Application areas:

In the complex world of industrial automation and process control, ABB DSAI133A 3BSE018290R1 is an essential component that plays a critical role in various fields. In power plants, whether it is coal-fired, hydroelectric or solar power generation facilities, this analog input module is deployed to monitor key parameters. For example, it measures the temperature of turbines in thermal power plants to prevent overheating, which could lead to catastrophic failures. In solar power plants, it measures the voltage and current of solar panels to ensure optimal energy conversion and grid integration.

The manufacturing industry also heavily relies on ABB DSAI133A 3BSE018290R1. In the automotive manufacturing industry, it monitors and controls the pressure in the hydraulic system of the robotic arm used for precision assembly. In the food and beverage industry, it measures the flow rate of liquids during the bottling process to maintain product consistency and quality. In chemical plants, this module is essential for monitoring the concentration of various compounds in the reactor to ensure a safe and efficient production process. It can accurately capture and transmit analog signals in real-time, making it the cornerstone for maintaining process stability and improving overall productivity in these industries.

Related product introduction:

ABB DSAO130 3BSE018293R1- A well paired analog output module with DSAI133A 3BSE018290R1, capable of achieving closed-loop control systems. It can send control signals based on the input data received by DSAI133A.

ABB DSBC170 3BSE018170R1- Communication module to enhance overall system connectivity. It can work in conjunction with DSAI133A to ensure seamless data transmission between different components in the control network.

ABB DSAP120 3BSE018168R1- A power module that provides stable power to DSAI133A and other components in the system, ensuring reliable operation.

ABB DSQC697 3HAC025901-001- For applications involving robots, this module can be integrated with DSAI133A to receive sensor feedback for more precise robot control.

ABB DSDI110AV1- A digital input module that complements DSAI133A in hybrid control systems, allowing for simultaneous processing of analog and digital input signals.

Installation and maintenance recommendations:

Preparation before installation: It is crucial to ensure that the DIN rail of the installation module is correctly installed and grounded before installation. Check the power supply voltage to ensure it matches the requirements of the module accurately. When connecting analog inputs, use shielded cables to minimize electromagnetic interference. Leave sufficient clearance around the module for proper ventilation, as it generates heat during operation.

Maintenance suggestion: Regularly check the wiring for signs of looseness, corrosion, or damage. Use diagnostic tools provided by ABB to monitor the health status of modules, such as checking for channel specific faults. Regularly clean the module to remove dust and debris, especially in dusty industrial environments. Keep the firmware of the module up-to-date, as ABB frequently releases updates to improve performance, fix errors, and enhance security.

Other models of ABB series:

TVOC-2-240

TVOC-2-240 1SFA664001R1001

TVOC-2-240-C

TVOC-2-DP6 1SFA664003R1060

TVOC-2-E1

UAC383AE01 HIEE300890R0001

UAC389AE02 HIEE300888R0002

UAD142A01 3BHE012551R0001

UAD155A0111 3BHE029110R0111

UBC717BE101 3BHE021887R0101

UFC718AE01 HIEE300936R0001

UFC718AE101 HIEE300936R0101

UFC719AE 3BHB003041R0101

UFC719AE01 3BHB000272R0001

UFC719AE101 3BHB00072R0101

UFC765AE102

UFC911B104 3BHE037864R0104

UFC911B106 3BHE037864R0106

UFC911B108 3BHE037864R0108

UFC912A101 3BHE039426R0101

UFC921A 3BHE024856P106

UNC4673A HIEE205014R1

UNC4673AV1 HIEE205014R1

UNITROL 1010-0003 3BHE035301R410

UNITROL 1000 3BHE014557R0003

Unitrol 1000-7

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626