Description

What This Product Solves

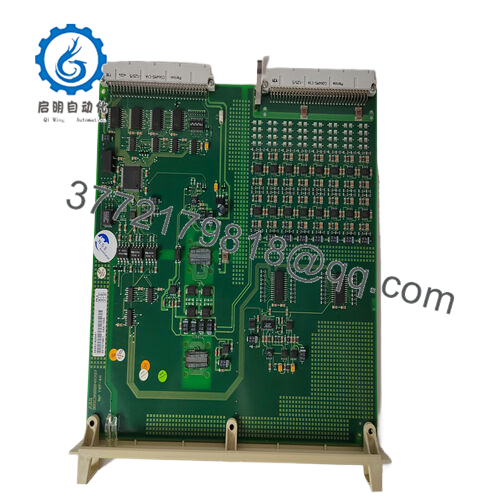

The ABB DSAI133A 3BSE018290R1 is a high-density analog input board designed for advanced industrial automation systems. It addresses the need for accurate and reliable analog signal acquisition, conversion, and processing, essential for precise monitoring and control in complex manufacturing and process environments. By delivering high channel density and robust performance, this module supports engineers in achieving stable process control, efficient data handling, and improved system reliability.

The ABB DSAI133A 3BSE018290R1 is particularly valuable in settings requiring numerous analog inputs for sensor signals such as temperature, pressure, and flow. These applications depend on precise signal measurement and conversion to maintain product quality and operational safety. Keywords such as “industrial automation,” “analog input,” “signal conversion,” and “process control” underscore its vital role.

How the Product Works & Fits into a System

The ABB DSAI133A 3BSE018290R1 functions as an analog input module that supports up to 16 single-ended or 8 differential input channels. It integrates into industrial control systems, converting analog signals into digital data for processing by central controllers. The module features a sampling rate of up to 50 samples per second per channel with an accuracy of ±0.1%, ensuring high-resolution data capture.

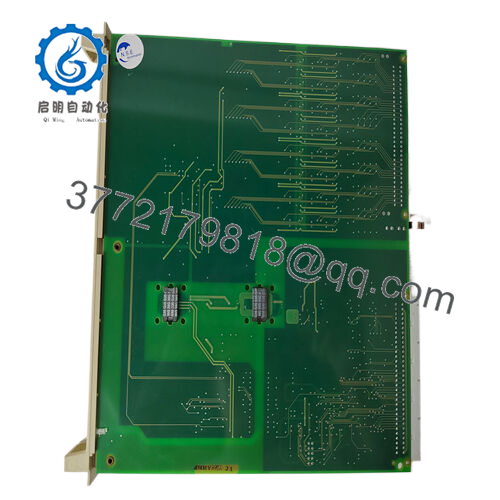

Dimensionally compact (approximately 16 cm × 16 cm × 12 cm) and weighing about 0.8 kg, the module mounts easily within control cabinets. It is designed to interface with ABB control platforms, providing scalable and modular signal acquisition capabilities essential for sophisticated automation projects. The module maintains stable operation across standard industrial temperature ranges.

- DSAI133A 3BSE018290R1

- DSAI133A 3BSE018290R1

Technical Highlights Summary (Table)

| Specification | Details |

|---|---|

| Model Number | DSAI133A / 3BSE018290R1 |

| Brand | ABB |

| Type | Analog Input Module |

| Input Channels | 16 single-ended / 8 differential |

| Sampling Rate | Up to 50 samples/second/channel |

| Accuracy | ±0.1% |

| Operating Temperature Range | Industrial standard |

| Dimensions | 16 cm × 16 cm × 12 cm |

| Weight | Approx. 0.8 kg |

| Mounting Style | Control cabinet |

Real-World Benefits

The ABB DSAI133A 3BSE018290R1 enables precise and reliable analog signal acquisition, crucial for accurate process control and monitoring. Its high channel density allows for efficient use of cabinet space and reduces wiring complexity. The module’s excellent accuracy and sampling rate ensure responsive control actions and stable product quality.

Its integration with ABB control systems simplifies system expansion and configuration, reducing engineering effort while enhancing data fidelity and system oversight. The robust construction helps ensure consistent long-term performance in harsh industrial environments.

Typical Use Cases

This module is used extensively in manufacturing, utilities, and process industries where numerous analog inputs from sensors require real-time monitoring and control. Typical applications include temperature and pressure monitoring in chemical plants, flow measurement in water treatment, and other industrial processes demanding high-resolution analog input data.

The ABB DSAI133A 3BSE018290R1 supports scalable automation systems where ease of integration and signal quality are essential for maintaining process safety and efficiency.

Compatible or Alternative Products

DSAI133A 3BSE018290R1 – High-density analog input module.

3BHE006412R0101 UFC762AE101 – Industrial control and excitation management module.

216AB61 HESG324013R100 – Digital output module for protection and control.

07KT98C GJR5253100R028 – Advant Controller 31 basic unit for automation.

3BHB005243R0106 KUC755AE106 – Power exciter control module.

Setup Notes & Maintenance Insights

Prior to installation, verify system compatibility with module input requirements and control platform interfaces. Ensure proper mounting in control cabinets with adequate ventilation. Verify wiring to sensors and signal sources is secure and conformant with standards.

Regular maintenance involves checking input channel functionality, verifying sampling accuracy, and firmware updates when available. Keeping connectors clean and monitoring diagnostic indicators helps prevent data acquisition errors and ensures continuous reliable operation.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626