Description

In sprawling steelworks where electric arc furnaces melt scrap into molten rivers at temperatures pushing 1,700°C, maintaining precise power delivery is non-negotiable—too much ripple, and electrodes erode prematurely; too little, and the melt stalls, costing thousands per hour. That’s where accessory boards like the ABB DSAB-01C come into play, embedded in drive systems to handle thyristor triggering and diode rectification, ensuring smooth current flow that keeps operations on track. Shift to a bustling automotive plant in Detroit, cranking out electric vehicle batteries; here, the ABB DSAB-01C integrates into inverter stacks for conveyor drives, damping harmonics that could glitch robotic welders mid-shift. Or picture a paper mill in Finland, its massive rollers demanding variable-speed control amid fluctuating pulp loads—the ABB DSAB-01C supports fault-tolerant signaling to prevent paper tears or machine jams, upholding production quotas in a sector where downtime ripples through supply chains.

These boards find their stride in industrial automation for medium-voltage drives, addressing headaches like voltage sags in cement kilns or synchronization lags in marine propulsion setups on cargo ships crossing the Atlantic. In renewable energy tie-ins, such as offshore wind converters off the UK coast, the ABB DSAB-01C aids in grid-compliant power shaping, buffering against gust-induced transients that might destabilize feeders. It tackles real-world grit—vibrations from heavy machinery, dust in mining draglines, or humidity in pharmaceutical extruders—while enabling modular expansions that let engineers retrofit without full-system teardowns. Applicable in control systems for ACS800 series inverters, this accessory board fosters reliability in environments where every waveform counts, from oil rig pumps in the Gulf to textile winders in Bangladesh. By optimizing signal paths for low-loss operation, the ABB DSAB-01C turns potential bottlenecks into seamless throughput, empowering integrators to deliver systems that scale with demand and endure the grind.

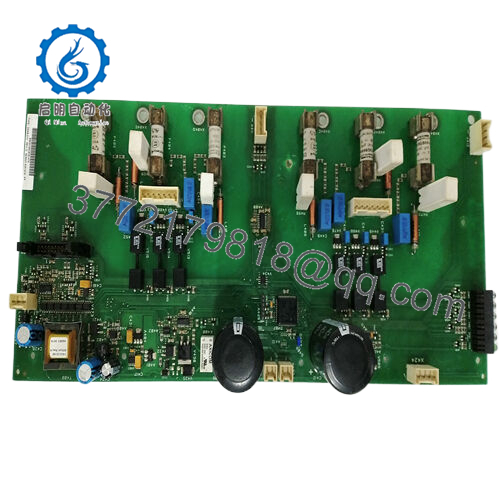

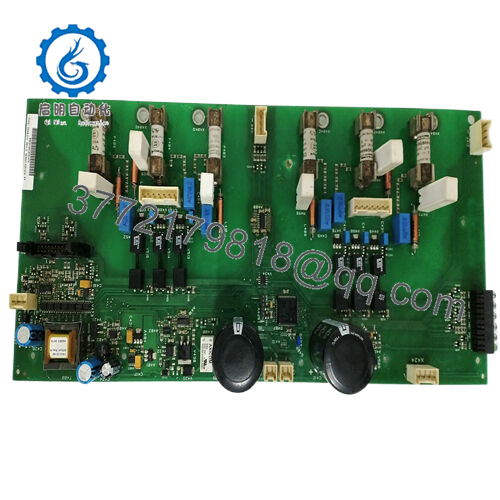

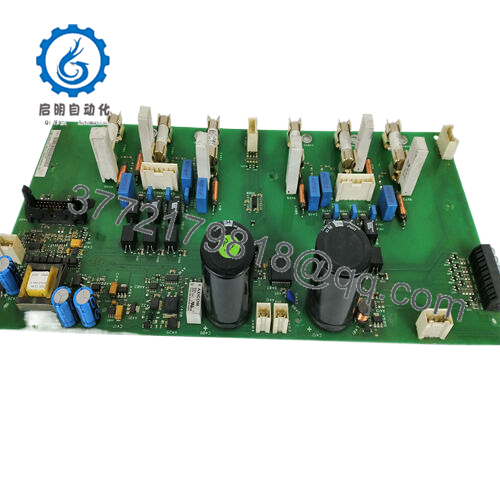

The ABB DSAB-01C is a versatile accessory board, often configured as a diode or thyristor module within ABB’s ACS800 family of AC drives, serving as a critical interface for power conversion and control signaling. It mounts directly onto main inverter stacks, managing rectification duties or gate-trigger pulses to synchronize semiconductor firing, all while feeding diagnostics back to the drive’s master controller. Part of ABB’s broader drive ecosystem, it slots into modular chassis alongside power stacks, supporting configurations from 100 kW to multi-megawatt setups in industrial motor control. For technicians, its plug-in design streamlines assembly, connecting via ribbon cables and bus bars to handle phase inputs without custom fabrication.

- DSAB-01C

- DSAB-01C

What elevates the ABB DSAB-01C in the field is its role as a bridge between raw power electronics and intelligent oversight—think of it as the unsung hero ensuring clean DC from AC grids for variable-frequency operations. It thrives in DCS-integrated plants, compatible with PROFIBUS for remote tuning, and offers scalability for parallel units in high-current arrays. Integrators favor it for reducing EMI in sensitive zones, with built-in snubbers that clamp transients during commutation. In architectures like those for crane hoists or compressor trains, it enables hot-pluggable swaps, minimizing arc flash risks during live maintenance. This board’s pragmatic engineering—focusing on thermal resilience over bells and whistles—makes the ABB DSAB-01C a staple for upgrading legacy ACS systems, where it boosts efficiency without inflating footprints or budgets.

Field crews swear by the ABB DSAB-01C for its rock-solid triggering accuracy, firing thyristors with jitter under 1 microsecond to sustain torque in high-inertia loads like rolling mills, where even minor phase errors amplify to mechanical stress. As a diode module variant, it rectifies with forward drops below 1 V, cutting conduction losses by up to 5% in continuous-duty cycles—vital for energy-hungry pumps in water utilities. Error handling is intuitive, with opto-isolated outputs that isolate faults, preventing cascade failures in stacked configurations. Its low power draw keeps overall drive efficiency humming, even at partial loads.

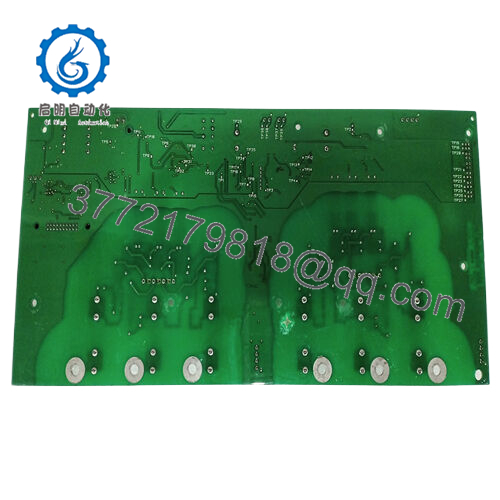

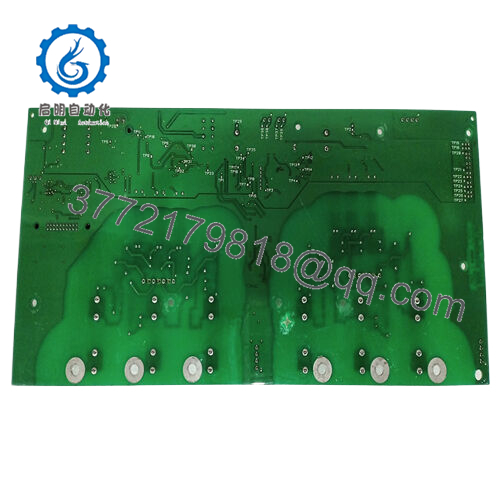

Hardware merits of the ABB DSAB-01C include a flame-retardant FR4 board rated 94V-0, conformal-coated for IP20 enclosures that fend off condensation in coastal refineries. Compact at roughly 37×17 cm, it snaps onto standard DIN rails with captive screws, easing retrofits in tight cubicles. Protocol support spans CANopen and DeviceNet for fieldbus tie-ins, while analog monitoring ports allow direct voltage feedback to HMIs. In vibration-prone spots like quarry crushers, its solder joints and potting withstand 5g shocks, backed by a design life exceeding 100,000 hours.

Reliability rounds out the ABB DSAB-01C‘s profile, with overvoltage clamps up to 1.5 kV and thermal cutoffs that self-recover after cooldowns, slashing nuisance trips in cyclic processes. Firmware-agnostic, it adapts to drive updates via jumper settings, ensuring longevity in evolving plants. For teams balancing uptime with compliance, this board delivers measurable gains in MTTR, proving its worth in setups where precision power steering directly fuels output.

| Parameter | Value |

|---|---|

| Model | DSAB-01C |

| Brand | ABB |

| Type | Accessory Board (Diode/Thyristor Module) |

| Power Supply | 10-30 V DC |

| Operating Temperature | -20°C to +70°C |

| Mounting | DIN rail or chassis mount |

| Dimensions | 375 mm x 168 mm x 55 mm |

| Weight | 0.65 kg |

| Interfaces | Ribbon cable, bus bars, CANopen/DeviceNet |

| Certifications | CE, UL 508, RoHS compliant |

| Cooling | Natural convection |

| Environmental Rating | IP20 (enclosure required for harsh environments) |

DSSB-01C – Control unit companion for DSU setups, providing supervisory logic that pairs with DSAB-01C for full inverter oversight.

DSMB-01C – Motherboard variant in the DSA series, handling expanded I/O for multi-phase rectification alongside DSAB-01C.

DSAB-02C – Enhanced successor with higher current handling, ideal for upgrading DSAB-01C in medium-voltage extensions.

ABRC-01C – Brake chopper relay card that integrates via shared bus, boosting regenerative control in drive arrays with DSAB-01C.

AINP-01C – Analog input processor module, complements DSAB-01C by conditioning sensor signals for precise thyristor feedback.

APOW-01C – Power supply accessory board, ensures stable DC rails for DSAB-01C in redundant power configurations.

NIOC-01C – Digital I/O extension unit, links to DSAB-01C for status monitoring and fault relay outputs.

Dropping the ABB DSAB-01C into a drive cabinet starts with mapping slot alignments—leave 25 mm gaps between boards to promote airflow, particularly in vertical stacks where heat rises fast. Anchor it firmly with M3 screws torqued to 0.5 Nm, and route bus bars with insulated boots to sidestep shorts; always verify polarity on diode bridges using a diode tester before energizing. For fieldbus hookups, employ twisted-shield pairs grounded at one end only, and cycle power twice post-install to clear any latch-up from shipping ESD. In multi-board bays, sequence activation to avoid inrush clashes, monitoring with a scope for clean waveforms under no-load.

Keeping the ABB DSAB-01C sharp means monthly LED scans for firing anomalies, cross-referencing against drive logs to trace ripple spikes back to upstream filters. Wipe solder joints with isopropyl annually in dusty mills, but power down fully to discharge caps first—residual voltage can bite. Diagnostics via ABB’s DriveWindow tool let you poll gate pulse counts, alerting to wear before efficiency dips below 98%. Jumper tweaks for protocol shifts are tool-free but document them in site records; in corrosive atmospheres like galvanizing lines, reseal edge connectors every two years. Planned swaps during annual shutdowns extend viability, focusing on thermal paste refresh under heatsinks for sustained performance.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626