Description

What This Product Solves

In modern control architectures, reliable, maintainable relay outputs are essential for safe and deterministic plant operations. The DO802 module provides eight independently isolated relay outputs with a broad voltage range, enabling direct control of actuators, valves, or signaling devices across industrial environments. This device is particularly valuable when upgrading legacy I/O, expanding backplanes, or integrating disparate control systems where each channel must operate with galvanic isolation and clear fault signaling. For engineers, the key benefit is predictable behavior under load, straightforward wiring, and transparent diagnostics that reduce troubleshooting time and minimize unplanned downtime. In practice, DO802 helps facilities achieve higher process control reliability, safer interlocks, and more modular automation architectures, making it a sensible choice for both expansions and retrofits in process industries, energy facilities, and discrete manufacturing. The model name is a recognizable anchor for teams standardizing on ABB’s S800 I/O family, ensuring compatibility with existing backplanes and control stacks. The DO802 is a practical, field-proven solution for robust digital relay outputs in challenging environments.

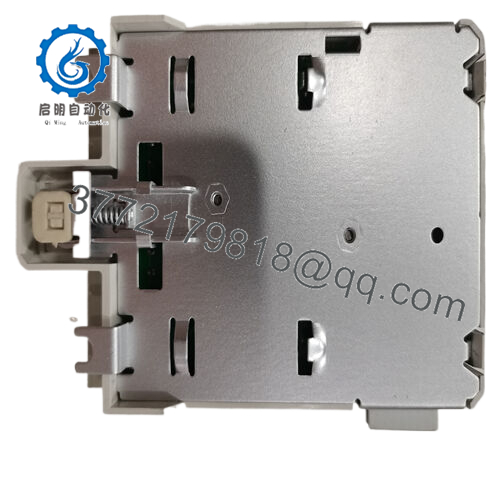

How the Product Works & Fits into a System

The DO802 module functions as a digital output relay board within ABB’s S800 I/O system. It slots into an industrial controller’s I/O backplane, delivering eight independently isolated NO relay outputs for direct control of external devices. Each channel typically includes a relay, LED status indicator, driver circuitry, and EMC protection, with isolation between channels to prevent cross-talk and fault propagation. The module is designed to communicate with the central controller via the standard ModuleBus, supporting safe supervision of relay power and status across the network. In a typical automation stack, DO802 sits at the field I/O boundary, bridging plant signals to the control layer, and enabling straightforward maintenance, channel-level fault detection, and clear status feedback. This arrangement supports modular expansion, straightforward diagnostics, and reliable interlock and signaling schemes across multi-rack systems. The model name DO802 remains the reference point for compatibility with neighboring digital I/O and power modules in the ABB S800 family, helping engineers plan coherent upgrades and replacements. The DO802 is a dependable workhorse for reliable signaling in industrial automation environments.

Technical Highlights Summary (Table)

Specification | Details

Model Number | DO802

Brand | ABB

Type | Digital Output Relay Module

Input Voltage | 110 V dc / 250 V ac (NO) per channel

Channels | 8

Isolation | Channel-to-channel and channel-to-backplane isolation

Output Type | Normally Open relay (NO)

Max Output Current | [Value to be confirmed]

Max Output Voltage | 250 V AC / 110 V DC (per channel)

Power Consumption | [Value to be confirmed]

Operating Temp Range | [Value to be confirmed]

Mounting Style | DIN rail / chassis mounting (as applicable)

Dimensions | [Value to be confirmed]

Weight | [Value to be confirmed]

Interface/Bus | ModuleBus backplane (ABB), optional fieldbus adapters

Compliance | CE, RoHS

Spare/Diagnostics | Channel status indicators and supervision signals

Typical Power Draw | [Value to be confirmed]

- DO802

- DO802

Real-World Benefits

The DO802 is engineered for reliability in continuous operation environments, delivering eight independently isolated relay outputs with predictable performance. Its modular design reduces wiring complexity and enables straightforward expansion, so maintenance teams can replace or reconfigure channels without disturbing surrounding hardware. The isolation and robust EMC protection help prevent fault propagation from noisy devices, improving overall system reliability and safety interlocks. Clear channel-level indications and supervision signals enable rapid fault isolation, shrinking downtime during startup and ongoing operation. With its compatibility within the S800 family, DO802 supports coherent upgrades and standardized maintenance practices across multiple racks or plants, simplifying spare-part management and reducing engineering overhead. By providing a dependable digital output solution that performs consistently across environmental variations, this module helps systems achieve sustained uptime, safer operations, and clearer diagnostics throughout the plant lifecycle.

Typical Use Cases

Commonly deployed in process control and manufacturing environments where robust signaling is critical. The DO802 supports interlocks, valve actuation, alarm signaling, and other safety-critical outputs in power plants, chemical processing facilities, and large-scale water treatment plants. In discrete manufacturing, it enables reliable control of robotics, conveyors, and automated tooling where predictable relay operation is essential for safety and throughput. Its eight-channel density makes it well-suited for retrofit projects where a compact, isolated digital output solution is needed to replace aging relays or to expand existing I/O without overhauling the control topology.

Compatible or Alternative Products

Boldly consider these related models for upgrades or complementary components:

- DO801 – Earlier 8-channel relay module with similar form factor

- DO802E – Enhanced version with extended voltage range or diagnostics

- DO803 – 16-channel counterpart for higher I/O density

- DO804 – 32-channel or higher-density option within the same family

- DO810 – Expanded feature set for advanced signaling and diagnostics

- DO811 – Redundant-capable variant for critical applications

- DO812 – Updated revision with improved EMI performance

- DO820 – Next-generation digital output module with broader protocol support

Setup Notes & Maintenance Insights

Pre-installation checks should confirm compatibility with the host controller and ModuleBus backplane, including any required cable assemblies and termination. Ensure adequate clearance for ventilation and verify the supply wiring, gate drive, and safety interlocks align with plant requirements. After installation, perform a baseline function test, verify channel LEDs indicating status, and confirm supervision signals are correctly reported to the controller. Schedule periodic maintenance to inspect connector integrity, verify continuity of each channel, and conduct a yearly functional test to confirm relay actuation within specified tolerances. Maintain organized wiring diagrams and keep spare DO802 units or boards readily available to minimize downtime during fault events.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626