Description

In the relentless rhythm of a semiconductor fabrication cleanroom, where even a fleeting signal glitch can scrap a wafer worth millions, digital output modules like the ABB DO801 dictate the on-off dance of valves and actuators with unerring precision. Envision a biotech fermenter in a Swiss lab, brewing vaccine batches under sterile lockdown; the ABB DO801 channels commands to solenoid valves, toggling sterile air flows to maintain exact pH levels without contaminating the culture. Or consider an aluminum smelter in Quebec, its electrolytic pots guzzling power around the clock—the ABB DO801 orchestrates relay closures for anode adjustments, averting overcurrents that could halt production lines stretching kilometers. These modules embed in setups where split-second decisions control safety interlocks or batch sequencing, from wastewater treatment plants in California flushing contaminants via timed pumps to automotive paint shops in Wolfsburg, syncing spray nozzles to body contours for flawless finishes.

Deeper in, pulp and paper mills along the Mississippi lean on the ABB DO801 to fire up conveyor clutches amid steamy, fiber-laced air, countering jams that snag rolls and spike waste. In solar panel assembly lines in China, it drives stepper motors for precise tab welding, tackling dust and static that plague electronics. Used in industrial automation across hazardous zones, this module confronts hurdles like electromagnetic noise from nearby welders or thermal swings in enclosed cabinets, while enabling hot-swappable swaps to slash outage windows. Applicable in control systems for S800 I/O clusters, the ABB DO801 bolsters fault-tolerant designs, integrating with DCS platforms to log output states for audit trails in regulated sectors. By grouping channels for isolated signaling, it transforms scattered field devices into a cohesive network, letting engineers prioritize throughput over troubleshooting in environments where reliability isn’t optional—it’s the backbone of uptime in oil sands extractors or pharmaceutical fillers.

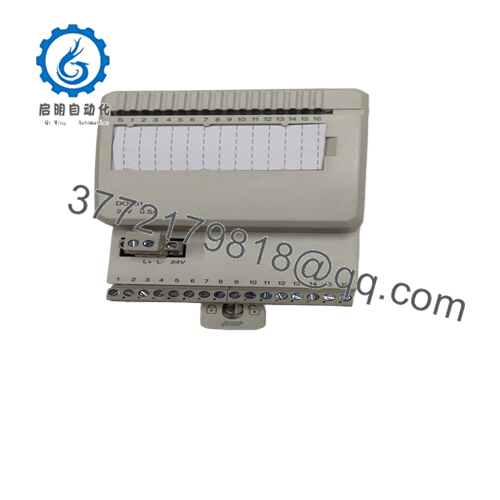

The ABB DO801 stands as a 16-channel digital output module in ABB’s S800 I/O portfolio, crafted to energize external loads like relays, indicators, or small solenoids in process control architectures. It operates as a current-sourcing unit, sinking up to 0.5 A per channel from a 24 V DC bus, and slots into modular I/O stations connected via ModuleBus to controllers like the AC 800M. Within ABB’s System 800xA ecosystem, it expands remote I/O drops, supporting up to 14 modules per segment for distributed layouts in sprawling facilities. Engineers deploy it for discrete signaling where analog finesse isn’t needed, bridging PLC logic to physical actuators with galvanic isolation to shield against ground loops.

Positioning the ABB DO801 as a workhorse for mid-sized plants, it strikes a balance between channel density and robustness, ideal for retrofitting legacy panels without footprint fights. Its value emerges in diagnostics—LEDs per channel flag states, while bus-integrated self-tests pinpoint shorts before they propagate. Compatible with PROFIBUS-DP for field-level comms, it eases ties to third-party sensors, and in redundant clusters, it mirrors outputs for seamless failover. Integrators count on its one-group isolation to compartmentalize risks, like segregating safety circuits from process ones. This setup streamlines commissioning in setups from batch mixers to conveyor sorters, where the ABB DO801 cuts wiring clutter and boosts signal integrity, freeing teams to scale without starting from scratch.

- DO801

- DO801

Operators in the trenches value the ABB DO801 for its bulletproof protections, clamping short circuits with electronic fuses that reset post-fault, sparing fuses in high-cycle apps like packaging lines where outputs flip thousands of times daily. Overvoltage suppression up to 32 V keeps loads safe during surges, while thermal shutdowns—triggered above 85°C—prevent latch-ups in sun-baked enclosures. Each channel’s 2 ms response time suits non-safety interlocks, delivering crisp edges that minimize contactor bounce in motor starters. The module’s field-side common wiring simplifies terminations, cutting install hours by grouping positives.

Build quality on the ABB DO801 screams endurance, with epoxy-sealed relays rated for 100,000 operations and conformal-coated boards shrugging off 95% humidity. At 16x10x12 cm and under 0.8 kg, it DIN-rails neatly in standard racks, with keyed connectors thwarting mix-ups during swaps. It meshes with S800 family via plug-in bus, and analog monitoring via HART if paired with gateways, though it shines standalone for pure binary tasks. In explosive atmospheres, its ATEX Zone 2 nod allows barrier-free use, dodging costly intrinsics.

Sustainability factors into the ABB DO801‘s longevity, with RoHS compliance and a 20-year service horizon backed by low-power logic that sips under 50 mA idle. Error logging via the I/O bus trends failures, like overtemps from blocked vents, enabling predictive swaps. For panels chasing IEC 61131 adherence, its deterministic timing ensures repeatable sequences, making the ABB DO801 a quiet enabler in loops where outputs drive everything from alarm horns to emergency dumps.

| Parameter | Value |

|---|---|

| Model | DO801 |

| Brand | ABB |

| Type | Digital Output Module |

| Power Supply | 24 V DC (10-30 V range) |

| Operating Temperature | -25°C to +60°C |

| Mounting | DIN rail (35 mm) |

| Dimensions | 160 mm width x 100 mm height x 120 mm depth |

| Weight | 0.8 kg |

| Interfaces | ModuleBus, screw terminals (2×18 positions) |

| Certifications | CE, UL 508, ATEX Zone 2, RoHS |

| Cooling | Natural convection |

| Environmental Rating | IP20 (NEMA 1 enclosure advised) |

DI801 3BSE020508R1 – Counterpart digital input module with 16 channels, pairs seamlessly for closed-loop feedback in S800 stations. DO802 3BSE020514R1 – Relay-based output variant for AC loads up to 250 V, complements DO801 in mixed-voltage panels.

AI801 3BSE020512R1 – Analog input module in the S800 series, expands the same bus for hybrid signal handling.

AO801 3BSE020513R1 – Analog output unit, integrates alongside DO801 for PID-driven actuator control.

CI801 3BSE020512R1 – Communication interface card, enables PROFIBUS connectivity for remote DO801 drops.

TB801 3BSE010210R1 – Terminal base for S800 I/O, provides fused connections to safeguard DO801 outputs.

SM810K01 – Supervised multiplexer module, links to DO801 for enhanced diagnostics in safety loops.

Fitting the ABB DO801 demands a quick scan of rack space—secure 20 mm overhead for cable routing, and align it with polarity marks on the bus connector to avoid backplane shorts. Torque terminals to 0.6 Nm with ferrules on 1.5 mm² wires, routing outputs away from power feeds to curb crosstalk; in Zone 2 spots, add zener barriers rated 28 V. Pre-power checks include continuity tests on commons and a megohmmeter sweep for isolation above 50 V—load-test a sample channel with a 48 Ω resistor to confirm 0.5 A hold without dropout.

Sustaining the ABB DO801 boils down to routine sweeps: bi-monthly peeks at status LEDs for stuck channels, paired with bus scans via Control Builder to log switch counts exceeding 50,000. Dust off vents with ionized air in linty mills, and cycle outputs dry during annual audits to verify contact resistance under 100 mΩ. Firmware flashes over Ethernet hit during lulls—snapshot the config first, then validate with a loopback plug. In steamy brewhouses, silica-gel packs in enclosures stave off condensation; replace the lithium backup every three years if uptime logs show drift. These habits keep faults at bay, turning the ABB DO801 into a set-it-and-forget-it staple.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626