Description

In industrial automation, capturing the pulse of field devices—switches, sensors, and limit detectors—without distortion or dropouts is the linchpin for responsive process control, yet legacy systems often falter when inputs flood in from noisy, high-density zones, breeding false alarms, erratic sequencing, or overlooked hazards that grind operations to a halt. Think of a steel mill where unfiltered proximity signals misfire furnace dampers, risking thermal runaway, or a pharmaceutical mixer where contact closures go undetected, compromising batch integrity and inviting compliance headaches. These scenarios highlight the imperative for a digital input module that delivers isolated, high-fidelity signal acquisition in legacy setups, and that’s where the ABB DI651 3BHT300026R1 proves its mettle as a 16-channel powerhouse, purpose-built for the rigors of Advant OCS environments where reliability trumps all.

Engineers maintaining or modernizing older DCS architectures frequently wrestle with modules that succumb to voltage transients or integration snags, leading to fragmented I/O architectures and escalated troubleshooting in time-sensitive upgrades. The ABB DI651 3BHT300026R1 fills this gap, offering galvanically isolated 48 VDC inputs that shield against common-mode noise, making it a staple for retrofits in power distribution or material handling where discrete signals must traverse long cable runs without degradation. In high-reliability contexts like offshore platforms or cement kilns, it ensures every pushbutton or level switch registers accurately, averting the chain reactions from missed inputs that could cascade into safety violations or production voids. Absent a module of this caliber, you’d contend with ad-hoc noise filters or frequent sensor swaps, siphoning budgets from strategic enhancements to patch-work fixes.

As industrial automation evolves toward hybrid legacy-modern hybrids, the thirst grows for I/O that embeds diagnostics without demanding full-system overhauls. The ABB DI651 3BHT300026R1 distinguishes itself with per-channel isolation up to 500 V, fortifying against ground shifts in shared cabinets while supporting hot-plug swaps to sustain uptime during live maintenance. It’s especially pivotal in migrations from standalone controllers to networked DCS, where preserving input fidelity directly bolsters operational resilience and audit readiness. This module transcends hardware—it’s the sentinel that converts raw field chatter into actionable intelligence, enabling your team to pivot from crisis response to data-driven foresight in demanding process control landscapes.

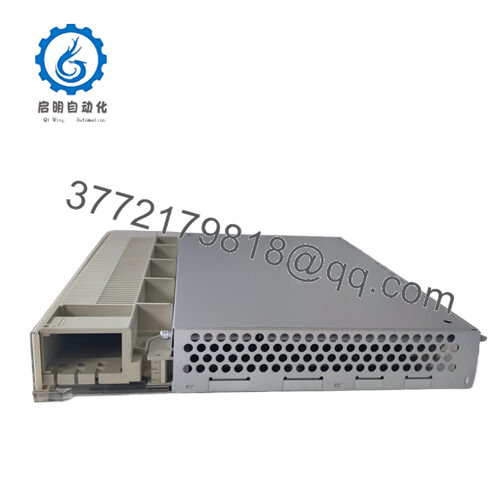

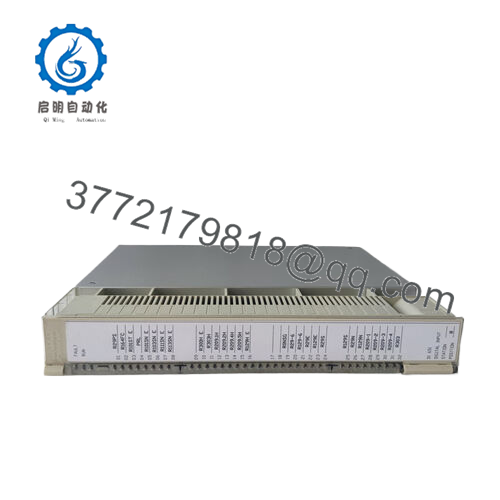

DI651

DI651

| Specification | Details |

|---|---|

| Model Number | 3BHT300026R1 |

| Brand | ABB |

| Type | Digital Input Module |

| Input Voltage | 48 V DC |

| Operating Temp Range | 0°C to 55°C |

| Mounting Style | DIN Rail (Advant Backplane) |

| Dimensions | 170 x 50 x 130 mm |

| Weight | 0.5 kg |

| Interface/Bus | S800 ModuleBus |

| Compliance | CE, UL, RoHS |

| Supported Protocols | Modbus, PROFIBUS |

| Typical Power Draw | 4 W |

The ABB DI651 3BHT300026R1 anchors the input layer in your automation stack, polling 16 discrete signals from field contacts or PLC outputs and relaying them via the ModuleBus to central processors for logic evaluation, positioning it as the vigilant gateway in Advant OCS backplanes where it interfaces with baseplates for scalable I/O expansion. It thrives in distributed architectures, drawing power from the rack while conditioning inputs to debounce mechanical bounces, ensuring clean edges that feed seamlessly into sequence controls or alarm matrices—envision it as the discerning filter in a sensor swarm, sifting valid triggers from transient glitches.

Seamless interplay defines its role: galvanic barriers per channel decouple field grounds from logic rails, so a nearby arc flash doesn’t corrupt the bus, and onboard filters tune response times from 1ms to 50ms for tailored sensitivity in vibration-heavy spots. Termination blocks snap on for field wiring, with diagnostics streaming fault bits—like open circuits or overvoltages—to supervisory software over PROFIBUS, empowering remote tweaks without panel breaches. In redundant arrays, it pairs with duplex controllers for bumpless transfer, upholding input integrity during failovers. Upstream, it populates tag databases in your HMI for operator visibility; downstream, it informs actuator decisions in the core loop, all within a footprint that accommodates legacy tie-ins to Modbus slaves. For growing setups, the ABB DI651 3BHT300026R1 extends effortlessly, hot-swappable to layer in more channels sans power cycles, bridging the old guard with IIoT-ready evolutions in a way that honors your existing investment.

Embracing the ABB DI651 3BHT300026R1 infuses your system with input assurance that sidesteps the pitfalls of signal flux, particularly in legacy loops where environmental grit routinely challenges detection thresholds. In the thick of shifts, this yields unwavering sequence fidelity—limit switches trigger sorters on the dot without phantom activations, honing throughput in sorting facilities and curbing the overtime from manual overrides that plague inconsistent modules. The isolation armor, in turn, absorbs transients that might demand auxiliary suppressors elsewhere, allowing your integrators to allocate efforts toward optimization rather than resilience retrofits, which streamlines project scopes and fortifies against the hidden costs of intermittent faults.

This module’s lineage speaks to battlefield-tested poise, with debounce logic that sustains accuracy through contact wear, easing the recalibration cadence in aging plants and preserving performance consistency amid throughput ramps. Field crews value the diagnostic clarity, as channel statuses mirror to asset portals for pattern spotting, often isolating cable faults before they strand outputs—slashing repair dispatches and amplifying mean time to detection. Crafted for the endurance of continuous duty, it aligns with sustainability mandates by minimizing idle scans, while its backplane affinity curtails engineering overhead in panel refreshes, letting you scale inputs without blueprint redraws.

Furthermore, the ABB DI651 3BHT300026R1 nurtures forward momentum: over-the-bus updates weave in protocol extensions, safeguarding relevance as DCS ecosystems blend with edge computing. This longevity lightens compliance footprints, with timestamped input logs furnishing evidentiary depth for ISO audits. Fundamentally, it’s an enabler of composed control, where steadfast signal capture unlocks efficiencies that cascade from sensor to strategy, recasting vulnerabilities into verified assets.

In metal fabrication shops, the ABB DI651 3BHT300026R1 monitors shear press foot pedals and position encoders, capturing 16 isolated inputs amid hydraulic clamor and dust, where fast data cycles and EMI resilience underpin critical system uptime in process control environments demanding split-second halts to avert jams. Its 48 V tolerance handles industrial sensors without level shifters, ensuring seamless integration for high-reliability forging sequences.

Gas compression stations rely on the ABB DI651 3BHT300026R1 for valve status and pressure switch polling in remote, corrosive outposts, thriving under thermal swings to deliver continuous uptime with diagnostics that flag line breaks early—essential for maintaining flow integrity without venting losses in pipeline process control.

Textile winding operations deploy the ABB DI651 3BHT300026R1 to track bobbin detectors and tension arms, enduring humid, lint-laden air with galvanic guards against static discharge, supporting high-speed inputs for defect-free runs in environments where input precision dictates yield and waste metrics.

DI652 3BHT300027R1 – Extended variant with 24 channels for denser sensor arrays in compact racks. IMDSI12 3BSE000802R1 – Legacy Infi90 input module for direct Advant OCS compatibility upgrades. DI610 3BSE008508R1 – S800-series counterpart with non-floating inputs for modern DCS transitions. DI811 3BSE008552R1 – High-speed digital input alternative for time-critical event capture. DSDI115 3BSE019934R1 – Relay-based input kit for inductive load buffering in hybrid setups. IMDSI14 3BSE000804R1 – Older generation unit for phased migrations from Net90 frameworks. DI890 3BSE038663R1 – Fieldbus-enabled version for distributed I/O in expansive networks.

Prior to seating the ABB DI651 3BHT300026R1 in your baseplate, cross-reference bus addressing with the controller’s map—duplicates spark enumeration conflicts that delay startup; ABB’s legacy tools can simulate this offline. Gauge enclosure ventilation against the rack’s aggregate heat, as clustered inputs nudge temps upward—target under 40°C inlet with passive fins if fans lag. Confirm field voltage stays within 40-60 VDC tolerance via a clamp meter on pilot runs, and prep termination with ferrules to thwart strand migration under vibration. A dry-run loopback test on a spare plate validates debounce settings, unearthing wiring inversions pre-commissioning.

Sustained care revolves around attuned vigilance. Biweekly LED patrols reveal stuck inputs or bus drops—probe suspect channels with a dry contact simulator to confirm, swapping fuses if draw exceeds 5 mA idle. Semiannually, audit cable shields for continuity and reseat plugs with 0.4 Nm torque, vital in oily atmospheres where ingress accelerates pitting. Harness diagnostic exports to trend input chatter rates, cueing sensor health before erosion bites; in certified loops, dovetail with SIL proofing by injecting faults quarterly. These practices, folded into rounds, sustain the module’s acuity without scripting special halts, yielding insights that guide refreshes proactively.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626