Description

Real-World Use & Application Scenarios

Modern industrial plants rely on precision power conversion and motor control to maintain productivity and efficiency. Whether in steel rolling mills, pulp and paper lines, or heavy conveyor systems, reliable drive technology ensures consistent performance under demanding conditions. The ABB DCF503-0050 is widely used in these environments as part of DC drive systems, helping operators achieve stable speed regulation and smooth torque control in applications where AC drives are not the best fit.

In sectors like mining, DC motors remain common for hoists and crushers due to their torque characteristics. The ABB DCF503-0050 serves as a key power module, ensuring controlled delivery of current to maintain safety and avoid costly downtime. In paper mills, precise web handling requires exact tension control—this module supports drive systems in achieving that accuracy. Similarly, in metallurgy, rolling mills depend on DC drive reliability to handle variable loads without process interruptions.

By acting as a core component in ABB’s DCS500 drive family, the ABB DCF503-0050 ensures older but proven DC systems remain competitive in modern automation landscapes. It provides industrial operators with the confidence that critical processes will run smoothly, integrating into existing architectures without requiring complete system replacement.

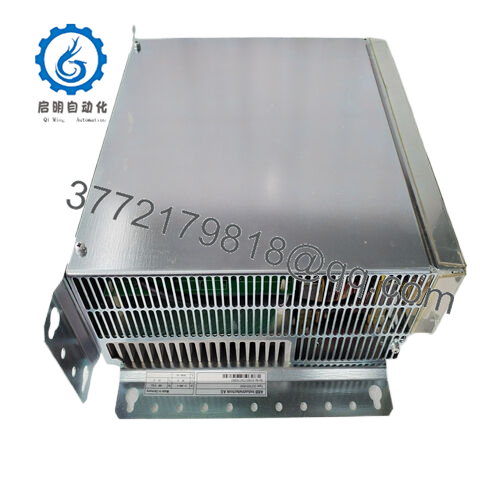

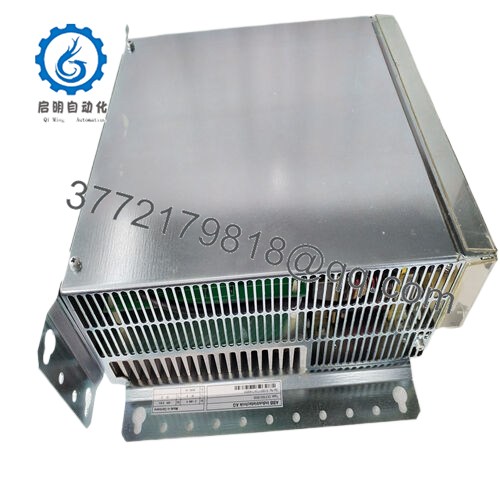

DCF503-0050

Product Introduction & Positioning

The ABB DCF503-0050 is a DC converter module designed for integration within the ABB DCS500 drive series. Its role is to provide controlled rectification and power conversion for DC motors, offering smooth performance even under fluctuating load conditions. Engineers often deploy it in heavy-duty applications where high torque and precise regulation are required.

Within ABB’s portfolio, the ABB DCF503-0050 is positioned as a reliable replacement and support component for DC drive systems. Instead of forcing plants to migrate to entirely new AC drive technologies, it allows continued use of existing DC installations while still benefiting from ABB’s engineering quality. For system integrators, this means reduced upgrade complexity, minimized downtime, and protection of long-standing infrastructure investments.

For maintenance teams, the module’s compatibility with established ABB control and monitoring platforms simplifies integration. Its design emphasizes stability, safety, and long-term performance, making it a trusted choice for engineers working in mission-critical industries.

Key Technical Features & Functional Benefits

The ABB DCF503-0050 is built with industrial-grade reliability, capable of handling continuous operation in tough plant environments. It offers precise control of DC current and voltage, ensuring smooth acceleration and deceleration of motors—a critical factor in preventing mechanical stress on connected equipment.

From a design perspective, the module is compact and engineered for easy integration within DCS500 cabinet configurations. It uses ABB’s proven cooling and thermal management design, which helps extend component lifespan and reduces the risk of overheating during high-load operations.

Another major benefit of the ABB DCF503-0050 is its compatibility with ABB’s existing DC drive ecosystem. Plants using earlier ABB DC drives can rely on this module for replacement or expansion, reducing total cost of ownership and extending the service life of capital assets. Its robust electrical design ensures resistance to disturbances like voltage dips, making it suitable for industries where power quality cannot always be guaranteed.

Long-term performance is also a strength: the module’s design minimizes maintenance needs, while ABB’s diagnostics and monitoring support help operators identify issues early. This reduces unplanned downtime, helping facilities keep production targets on track.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | DCF503-0050 |

| Brand | ABB |

| Type | DC Converter Module |

| Power Supply | 50 A DC drive module (DCS500 series) |

| Operating Temperature | 0 to +40 °C (derating above this range) |

| Mounting | Cabinet installation within DCS500 system |

| Dimensions | Approx. 270 × 190 × 200 mm |

| Weight | ~6 kg |

| Interfaces | Integrated with DCS500 control boards |

| Certifications | CE, UL (depending on market) |

| Cooling | Forced air cooling |

| Environmental Rating | Industrial use, vibration and EMC compliant |

Related Modules or Compatible Units

- ABB DCF502-0035 – Smaller capacity converter module for lighter DC motor applications.

- ABB DCF504-0070 – Higher current rating for heavy-duty load conditions.

- ABB SDCS-PIN-51 – I/O extension board used with DCS500 systems for enhanced control functions.

- ABB SDCS-IOB-23 – Input/output module compatible with DC drives, enabling field signal integration.

- ABB SDCS-CON-2 – Control board for DCS500, works in combination with the DCF503-0050.

- ABB DCF505-0100 – Extended version for higher motor power requirements.

Installation Notes & Maintenance Best Practices

Before installing the ABB DCF503-0050, engineers should confirm cabinet space and ventilation conditions meet ABB’s specifications. Proper grounding and cable routing are essential to reduce EMC interference and ensure safe operation. It is advisable to maintain adequate clearance for airflow around the module, especially in enclosures with multiple high-power components.

In terms of maintenance, operators should perform regular inspections of cooling fans, heat sinks, and electrical connections. Dust accumulation should be cleared during planned shutdowns to maintain thermal efficiency. Periodic checks on drive diagnostics through the DCS500 control system can help detect early signs of wear or abnormal current fluctuations. Firmware and parameter backups should also be maintained for quick restoration in case of module replacement.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626