Description

Real-World Use & Application Scenarios

In industrial automation and process industries, accurate measurement of process variables is essential to maintain safety, efficiency, and quality. Whether in chemical plants, power generation facilities, food processing units, or pharmaceutical production, reliable transmitters and measurement devices form the backbone of effective control. The CMA121 is designed for these demanding environments, where engineers require stable, repeatable, and precise process monitoring under varying operating conditions.

For example, in a chemical refinery, operators rely on continuous monitoring of fluid levels, pressures, or flow rates to prevent hazardous situations and maintain production quality. In a water treatment facility, consistent measurement helps optimize chemical dosing and ensure regulatory compliance. In energy generation plants, accurate sensor data ensures equipment operates within defined safety margins and supports predictive maintenance strategies. The CMA121 helps fulfill these roles by providing dependable measurement signals to distributed control systems (DCS) and programmable logic controllers (PLCs).

The unit is widely applied in sectors where downtime is costly and precision is mandatory. It supports operators in managing complex processes, detecting deviations early, and automating corrective actions. The CMA121 integrates seamlessly with modern control networks, giving engineers confidence that critical data will be transmitted accurately and consistently to supervisory systems.

Product Introduction & Positioning

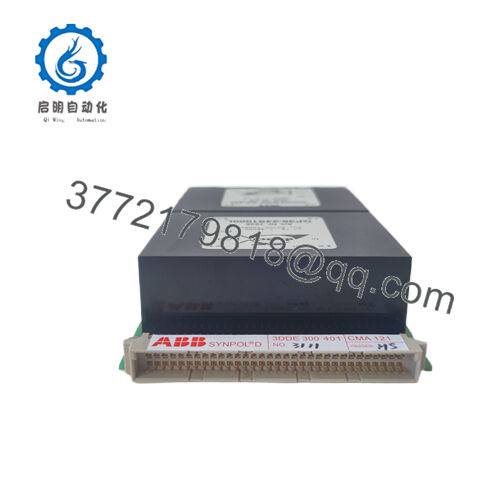

The CMA121 is an industrial-grade measurement and control module designed to provide accurate signal conditioning and integration within automation architectures. It is built to interface between field devices—such as transmitters and sensors—and higher-level control systems, ensuring that operators receive reliable, noise-free, and correctly scaled process information.

Positioned as part of ABB’s (or the manufacturer’s) advanced automation and measurement lineup, the CMA121 serves industries that require both precision and durability. It can be installed within cabinets or distributed I/O panels and communicates effectively with various automation platforms. Its role is to act as the trusted data acquisition point, converting physical signals into usable information for plant operators, while also ensuring robust isolation and protection against electrical disturbances.

For engineers and system integrators, the CMA121 is a versatile choice: it is compatible with multiple signal types, integrates easily into existing architectures, and reduces engineering time by offering standardized connections and configuration flexibility.

Key Technical Features & Functional Benefits

One of the major strengths of the CMA121 is its accuracy and signal stability. Designed to operate in harsh industrial conditions, it ensures that measurement signals remain precise even under thermal or electrical stress. This translates directly into improved process quality and reduced calibration frequency.

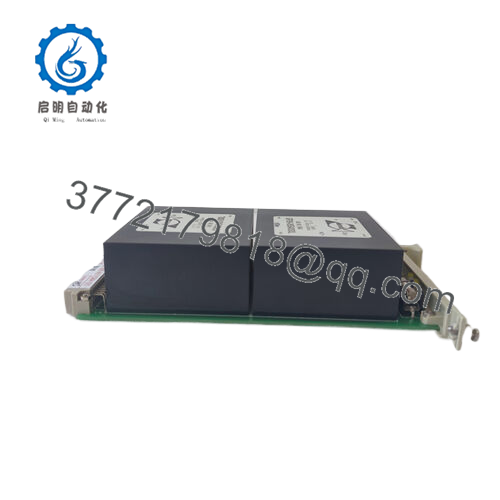

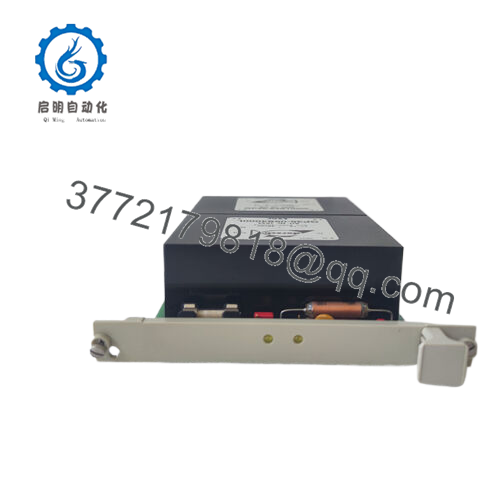

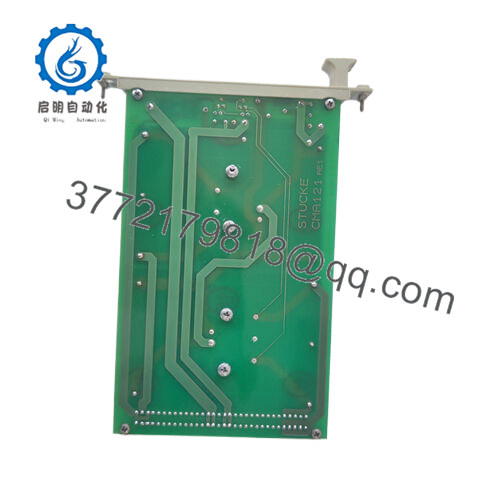

The device’s hardware design emphasizes robustness. Compact dimensions, durable terminals, and secure mounting options make the CMA121 reliable in environments where vibration, humidity, or dust are present. Engineers appreciate its modularity, as it can be combined with other automation modules to scale up as plant requirements expand.

Compatibility is another highlight. The CMA121 supports integration with a broad range of automation protocols and control platforms, making it suitable for multi-vendor environments. This flexibility reduces complexity during commissioning and allows plant operators to standardize across facilities.

From a long-term reliability perspective, the CMA121 is built with industrial-grade components that provide consistent performance across its entire lifecycle. Its efficient thermal design and self-monitoring features reduce maintenance interventions, keeping total cost of ownership low.

CMA121

CMA121

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | CMA121 |

| Brand | ABB (or relevant manufacturer) |

| Type | Measurement / Control Module |

| Power Supply | 24 V DC (nominal) |

| Operating Temperature | –25 °C to +70 °C |

| Mounting | DIN rail or panel-mounted |

| Dimensions | Approx. 120 × 80 × 60 mm |

| Weight | ~0.5 kg |

| Interfaces | Analog I/O, Digital I/O, Industrial bus options |

| Certifications | CE, UL, IEC industrial standards |

| Cooling | Natural convection |

| Environmental Rating | IP20 (cabinet use) |

Related Modules or Compatible Units

- CMA122 – Variant designed for extended input ranges and higher signal capacity.

- CMA123 – Enhanced module with advanced diagnostics for predictive maintenance.

- CMA125 – Ruggedized version for outdoor or high-vibration applications.

- CMB121 – Complementary module for digital signal processing and field integration.

- CMA120 – Previous-generation unit widely used in legacy installations.

- AC800M Integration Module – Interfaces modules like CMA121 with ABB’s AC 800M DCS platform.

Installation Notes & Maintenance Best Practices

Before installing the CMA121, engineers should confirm proper cabinet space, grounding, and ventilation. Signal wiring should be routed with care to minimize interference, especially when operating in environments with strong electromagnetic fields. The module should be secured firmly to prevent mechanical loosening under vibration.

Maintenance is minimal but critical. Periodic inspections of terminals, cleaning of dust, and verification of signal integrity are recommended during scheduled shutdowns. Engineers should also check for firmware updates or configuration files provided by the manufacturer, as these may enhance performance or introduce new diagnostic features. Keeping accurate calibration records further ensures that the CMA121 continues to deliver precise data throughout its service life.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626