Description

Real-World Use & Application Scenarios

The ABB CI626A 3BSE005029R1 finds its core applications in demanding industrial automation environments that require reliable, real-time digital signal management. It is prominently used in electrical power generation and distribution systems, where stability, safety, and early fault detection are critical. Power plants and grid substations rely on this module to monitor the operational conditions of transformers, switchgear, and power generation equipment, ensuring continuous and efficient energy flow. Beyond power sectors, this robust communication interface is equally valuable in industrial manufacturing floors. It handles data signals from sensors measuring temperature, pressure, and flow, providing precise feedback for production processes. The module’s capacity to integrate with programmable logic controllers and supervisory control systems makes it indispensable in automated factory lines, where timing and signal integrity affect overall product quality and throughput. The ABB CI626A 3BSE005029R1 is also applicable in broader control systems such as building automation and intelligent transportation, where coordinated monitoring and control of multiple digital signals contribute to operational efficiency and safety. Its design addresses the challenges of harsh electromagnetic environments, where noise and interference can degrade data integrity, making it a go-to solution for engineers aiming for resilient automation infrastructure.

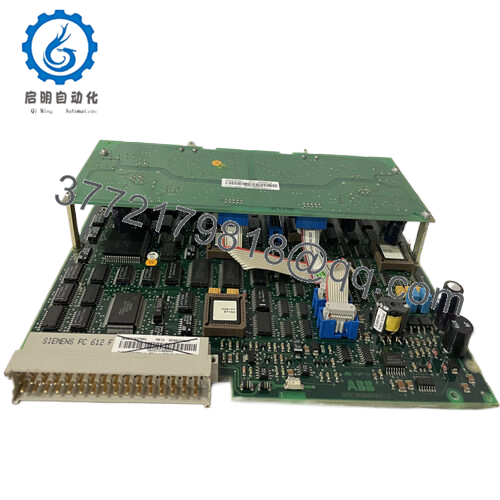

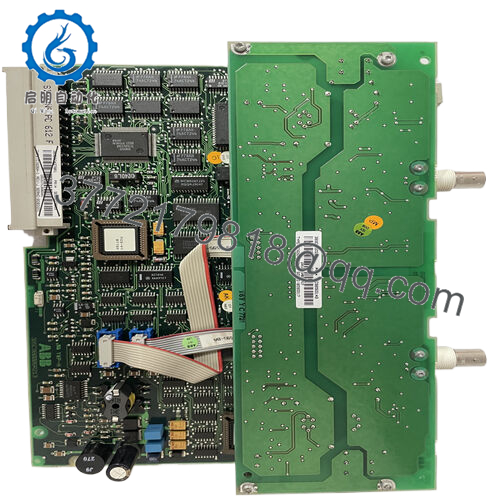

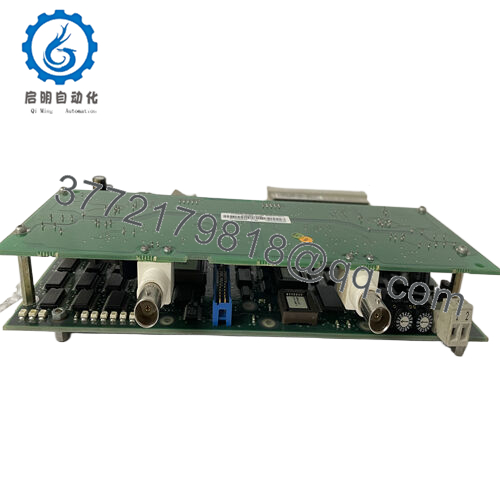

Product Introduction & Positioning

The ABB CI626A 3BSE005029R1 is a digital input/output communication interface module designed to act as a critical intermediary within industrial control architectures. Part of ABB’s renowned automation portfolio, the CI626A serves as a bus administrator board in the 800xA and Advant Fieldbus control systems. Its primary function is to facilitate communication between field devices and control systems, serving both as a data gateway and signal converter. The module supports standardized industrial communication protocols including Ethernet/IP and Modbus TCP/IP, allowing seamless systems integration across diverse automation platforms. Within the hierarchical control system, it fits between sensors, actuators, and central processing units, transmitting clean, reliable digital signals essential for real-time monitoring and control. This positioning grants engineers and system integrators a versatile tool to ensure synchronization and media redundancy, enhancing fault tolerance across the network. The ABB CI626A 3BSE005029R1 is esteemed for its straightforward compatibility with ABB PLCs and other major vendors’ control units, making it a valuable asset in modern industrial automation strategies.

- CI626A 3BSE005029R1

Key Technical Features & Functional Benefits

The ABB CI626A 3BSE005029R1 is engineered for high performance in challenging industrial conditions. Its communication speed leverages Ethernet protocols augmented by EtherCAT technology, reducing bus latency and maximizing data throughput for real-time control applications. The unit’s hardware is built to withstand harsh environments, with operational temperature tolerance from -40°C to +85°C and resistance against high humidity levels up to 95%. This rugged design features push-in terminal connectivity and a compact form factor optimized for panel mounting, helping preserve space without compromising accessibility or ease of wiring. Thoughtfully developed to filter electromagnetic interference, the module maintains signal integrity in noisy industrial settings, enhancing overall system stability. Its ability to self-diagnose and report error states significantly reduces downtime and maintenance complexity by pinpointing faults immediately. Engineers value its flexible parameter configuration options, which allow tailored I/O setups and communication settings through firmware or software interfaces. Importantly, the CI626A supports long service life through thermal efficiency and robust component selection, ensuring reliability and minimal lifecycle costs even in continuous 24/7 operations. This combination of durable construction and sophisticated digital processing makes the ABB CI626A 3BSE005029R1 well-suited for industries where precision, uptime, and safety cannot be compromised.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | ABB CI626A 3BSE005029R1 |

| Brand | ABB |

| Product Type | Digital I/O Communication Module |

| Power Supply | 24 V DC |

| Operating Temperature | -40°C to +85°C |

| Storage Temperature | -40°C to +85°C |

| Mounting | Panel Mount |

| Dimensions | Approximately 20 x 10 x 24 cm |

| Weight | ~2 kg |

| Interfaces | Ethernet/IP, RS485, Push-in Terminals |

| Communication Protocols | Ethernet/IP, Modbus TCP/IP |

| Certifications | CE, UL, ATEX compliant |

| Cooling | Passive Cooling |

| Environmental Rating | Industrial standard (high EMI resistance) |

Related Modules or Compatible Units

ABB CI627A – Companion bus administrator with twisted pair support for redundant media.

ABB CI526 – Earlier communication interface with coaxial connectors, suitable for less demanding environments.

ABB CI630 – Advanced module with broader channel options for larger systems.

ABB CI527A – PCI-based communication interface with enhanced synchronization capabilities.

ABB AC800M – Programmable logic controller compatible for integrated automation solutions.

ABB PM810V2 – Processor module for Advant Fieldbus systems with integrated communication features.

Installation Notes & Maintenance Best Practices

When installing the ABB CI626A 3BSE005029R1, it’s critical to ensure that the control cabinet provides adequate ventilation and space for safe mounting. Proper grounding is essential to minimize electromagnetic interference and protect the device from electrical surges. Installers should maintain recommended clearances around the module for heat dissipation and easy access to communication wiring and terminals. Use shielded cables for signal lines to enhance noise immunity in electrically noisy environments typically found in industrial plants. Maintenance should include routine visual inspections to check for loose connections, dust accumulation, and signs of wear or damage to wiring terminals. Regularly verify communication signals using system diagnostics tools to detect any data inconsistencies or interruptions early. Firmware updates, when issued by ABB, should be applied carefully to maintain device compatibility and improve functionality. Documenting configuration settings before updates prevents loss of custom parameters. Overall, scheduled checks combined with prompt troubleshooting reduce downtime and extend the module’s reliable service life.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626