Description

Real-World Use & Application Scenarios

Industrial plants operate under conditions where even small disruptions can escalate into costly downtime. Whether in steel rolling mills, chemical refineries, power plants, or high-capacity paper production lines, automation systems must deliver stability, safety, and scalability. Components such as the ABB 802A028D-3 are critical because they ensure that process control remains precise while equipment performance is optimized.

This module is frequently deployed in industrial automation systems, particularly within ABB’s distributed control and drive platforms. Its role is to support control reliability in environments that demand uninterrupted operation. For example, in petrochemical plants, where pumps and compressors must remain synchronized, the ABB 802A028D-3 contributes to error-free data handling and rapid signal response. In the metals industry, where rolling equipment is exposed to fluctuating mechanical loads, its robust design ensures drives continue functioning with minimal deviation.

Energy-intensive facilities also benefit from its reliability. In gas turbines, power generation units, and offshore rigs, this module helps sustain real-time communication between controllers and field devices. Its application extends to areas where compliance with safety and efficiency standards is vital—operators cannot risk unscheduled downtime or unstable automation sequences.

In short, the ABB 802A028D-3 answers the industrial challenge of maintaining productivity under stress. By securing system stability, enabling smooth communication, and resisting environmental interference, it has earned a reputation as a trusted element in ABB’s automation architecture.

Product Introduction & Positioning

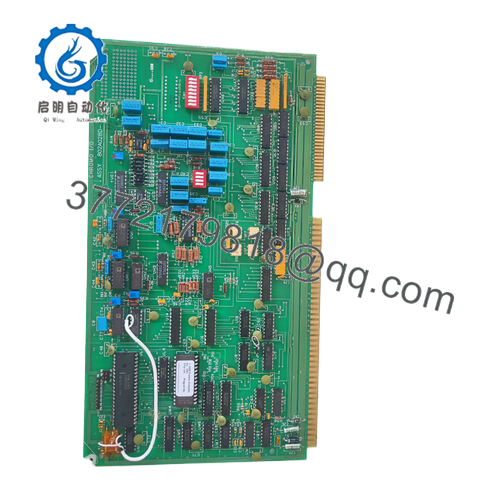

The ABB 802A028D-3 is a specialized control and interface module developed for integration into ABB’s automation and drive ecosystems. It serves as a link between field-level inputs and higher-level controllers, allowing industrial processes to operate with precision and consistency. By processing signals and ensuring compatibility across the control hierarchy, it plays an essential role in the broader system architecture.

Within ABB’s modular platform, the ABB 802A028D-3 is valued for its scalability. System integrators can incorporate it into existing racks or cabinets without major redesigns, making it suitable for both new installations and modernization projects. Its compatibility with ABB’s legacy and current platforms extends equipment lifecycles, which is a major advantage for operators managing multi-decade infrastructure investments.

What sets it apart is the balance between compact hardware design and dependable functionality. Engineers benefit from its predictable performance, while maintenance teams appreciate its straightforward replacement process. In demanding industries where time is money, the ABB 802A028D-3 is not just a spare part but a key enabler of continuous operation.

Key Technical Features & Functional Benefits

The ABB 802A028D-3 is built with a strong emphasis on reliability. Its primary strength lies in maintaining stable communication across control systems, ensuring that data integrity is preserved even in noisy industrial environments. This reduces the likelihood of faults caused by electrical interference or signal degradation.

Hardware durability is another distinguishing feature. The module is constructed to withstand vibration, thermal variations, and the kinds of stress common in heavy industries. Its compact form factor makes installation simple, while its robust casing offers added protection. Engineers working in confined cabinet spaces or mobile plant rooms will find this particularly valuable.

Compatibility also plays a central role. The ABB 802A028D-3 integrates seamlessly with other ABB components, including both legacy modules and current-generation units. This makes it an attractive choice for operators pursuing incremental upgrades rather than complete system overhauls. By allowing smooth interoperability, it reduces engineering hours and commissioning risks.

Long-term dependability is further enhanced by ABB’s design philosophy, which emphasizes thermal efficiency and component longevity. With proper preventive maintenance, the ABB 802A028D-3 offers years of consistent service, minimizing unplanned shutdowns and contributing directly to reduced lifecycle costs.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | 802A028D-3 |

| Brand | ABB |

| Type | Control / Interface Module |

| Power Supply | 24 VDC (nominal, system supplied) |

| Operating Temperature | 0 °C to +55 °C |

| Mounting | Rack or cabinet installation |

| Dimensions | Compact ABB modular standard |

| Weight | ~1.0 kg |

| Interfaces | System backplane, field communication |

| Certifications | CE, UL, industrial compliance |

| Cooling | Passive with optimized airflow |

| Environmental Rating | Industrial-grade, vibration tested |

802A028D-3

802A028D-3

Related Modules or Compatible Units

- ABB 3BHE037864R0104 – Compatible module for extended communication within ABB’s automation systems.

- ABB 3BHE006373R0101 – Control board often paired with the 802A028D-3 in distributed system applications.

- ABB XVC769AE101 – Auxiliary module supporting stable data transfer and redundancy.

- ABB 3BHE019719R0101 – Earlier interface generation, commonly upgraded to improve reliability.

- ABB 5SHX1960L0006 – Drive component complementing automation modules in high-power applications.

- ABB 3BHB016120R0002 – Processor module that delivers additional computational support for control systems.

Installation Notes & Maintenance Best Practices

Prior to installing the ABB 802A028D-3, system integrators should verify that cabinet layouts allow sufficient airflow and grounding compliance. As with all rack-mounted ABB modules, ensuring proper seating within the backplane is critical to prevent intermittent communication faults. Cable routing must minimize interference, particularly in drive-heavy environments with high electrical noise.

For maintenance, ABB recommends periodic inspection of connectors, dust removal using dry air, and verification of signal diagnostics. Firmware updates should be performed according to ABB’s release cycles to maintain alignment with the latest control standards. By embedding these checks into preventive schedules, operators can extend the lifecycle of the ABB 802A028D-3 while minimizing unplanned downtime.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626