Description

What This Product Solves

In today’s demanding industrial automation environments, managing precise and reliable control of high-power electrical systems is essential for operational stability and efficiency. The ABB 5SHY3545L0014 industrial control module addresses this need by delivering robust, high-performance power control optimized for heavy-duty applications. Engineers tasked with driving three-phase motors, power converters, or similar equipment require dependable control modules that ensure consistent industrial process performance while minimizing downtime.

The ABB 5SHY3545L0014 becomes indispensable in settings where precise motor control, high accuracy, and durability under harsh conditions translate directly into sustained system stability and productivity. By focusing on delivering reliable control signals in high-voltage AC environments, it supports critical automation goals—improving power quality, increasing system uptime, and simplifying integration into complex plant architectures. Keywords like “industrial automation,” “process control,” “power control module,” and “high reliability” align closely with its essential role in bridging power electronics with control systems.

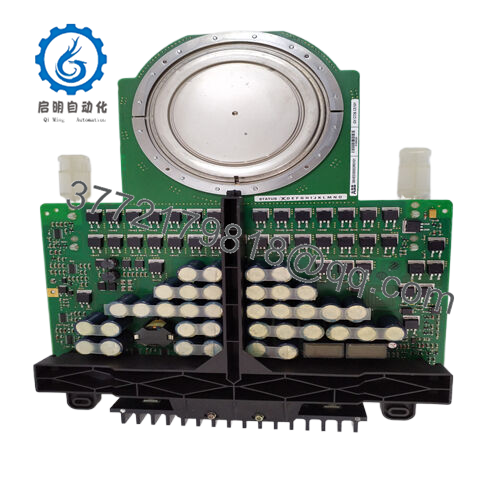

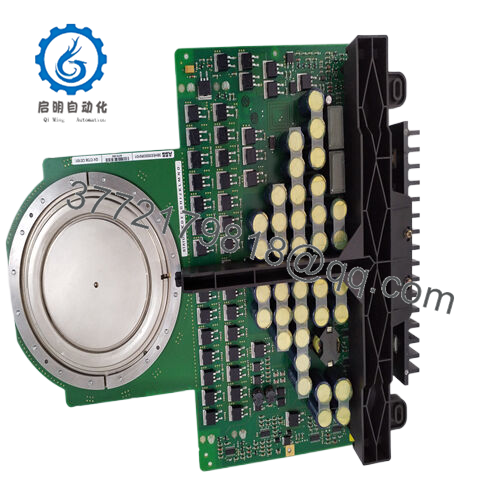

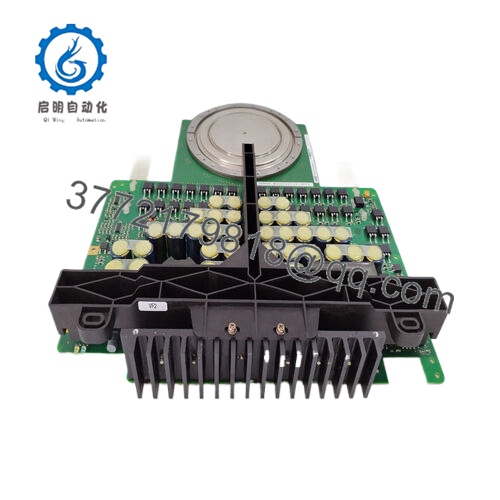

5SHY3545L0014

5SHY3545L0014

5SHY3545L0014

How the Product Works & Fits into a System

The ABB 5SHY3545L0014 functions as a high-precision industrial control module typically deployed within power control or motor control centers. It interfaces with power electronics equipment such as frequency converters or motor drives to regulate the electrical parameters needed for efficient operation of three-phase motors. Positioned strategically within the power control architecture, it effectively manages signal inputs and outputs that modulate voltage, current, and frequency in real time.

Designed to integrate into IEC 61131-2 compliant control systems, the ABB 5SHY3545L0014 fits into control cabinets or enclosures where modular, scalable industrial automation is required. Its rugged construction adheres to MIL-STD-810G standards, ensuring dependable performance in harsh industrial environments. The module supports automatic testing functions for bit error rates and status monitoring to provide diagnostics and improve maintenance routines, helping users maintain system reliability over time. Its dimensions and modular form factor allow straightforward installation alongside other industrial automation components.

Technical Highlights Summary (Table)

| Specification | Details |

|---|---|

| Model Number | 5SHY3545L0014 |

| Brand | ABB |

| Type | Industrial Control Module |

| Input Voltage | 380–480 V AC (typical) |

| Operating Temp Range | Industrial standard |

| Mounting Style | Control cabinet mounting |

| Dimensions | 140 x 90 x 65 mm |

| Weight | ~0.5 kg |

| Interface/Bus | IEC 61131-2 compliant |

| Compliance | IEC 61131-2, UL 508, MIL-STD-810G |

| Supported Protocols | Standard industrial protocols |

| Typical Power Draw | Application-dependent |

Real-World Benefits

The ABB 5SHY3545L0014 is engineered for robust performance in demanding industrial conditions, ensuring operators experience minimal downtime and consistent power control. Its high measurement accuracy, around ±0.05%, allows precision management of motor drives which is vital for processes requiring exact speed and torque control. This level of control enhances process stability and product quality in industries where even minimal deviations can lead to costly defects or system inefficiencies.

In addition, the module’s integrated status monitoring and automatic testing functions allow maintenance teams to detect power control anomalies early and plan interventions proactively, thus reducing emergency repairs and associated production losses. The ABB 5SHY3545L0014 also simplifies integration by conforming to widely adopted industrial standards, which reduces engineering overhead and accelerates deployment timelines.

Typical Use Cases

The ABB 5SHY3545L0014 finds broad application in power plants, manufacturing plants, and large-scale processing facilities where high-power motor control is crucial. It is frequently used in environments demanding resilient control through fluctuating electrical loads and harsh conditions, supporting continuous operation without compromising safety or efficiency. Typical conditions include fast response time requirements, critical system uptime, and rugged operation compliance.

In process industries such as chemical manufacturing, continuous uptime and precise control through equipment like pumps and compressors are critical, making the ABB 5SHY3545L0014 an ideal choice. It is also used in power distribution systems for managing large three-phase motors and providing stable control signals that improve overall plant reliability.

Compatible or Alternative Products

5SHY3545L0014 is part of a comprehensive portfolio of industrial control modules:

3BHB013085R0001 – A higher capacity control module for more demanding motor control applications.

5SHY3545L0010 – Alternative configuration with enhanced diagnostic options.

3BHE019719R0101 – Frequency converter module complementing control module functions.

3BHB019800R0001 – Power control module designed for integration with Siemens motor drives.

5SHY3545L0020 – Industrial control module with expanded input/output capabilities.

Setup Notes & Maintenance Insights

Before installing the ABB 5SHY3545L0014, verify compatibility with the existing IEC 61131-2 control system and ensure there is sufficient space in the control cabinet for mounting and ventilation. Confirm that all wiring meets local electrical standards and that the environment adheres to recommended temperature and humidity levels for the module’s optimal performance.

Once operational, maintenance consists primarily of reviewing diagnostic status indicators and testing performance parameters periodically, leveraging the module’s automatic testing function to monitor bit error rates. Connectors and wiring should be inspected annually to prevent power anomalies caused by loose connections or degradation. Proactive maintenance based on diagnostic feedback ensures the module sustains reliable operation and supports long-term automation goals.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626