Description

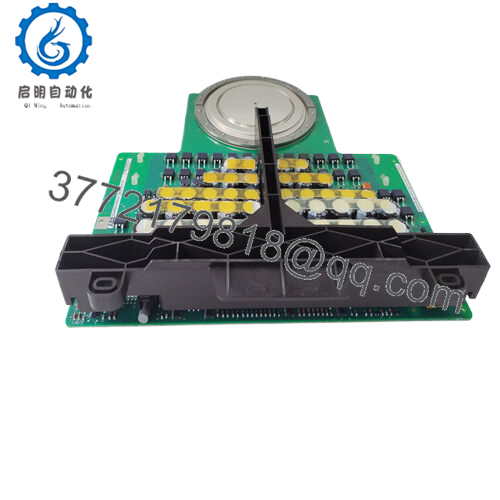

| Model Number | 5SHY2645L0004 |

| Brand | ABB |

| Type | Mid-Range Industrial Power Module (for Medium-Load VFD/Control Systems) |

| Input Voltage | 380–480V AC (3-phase) |

| Operating Temp Range | -10°C to 65°C (14°F to 149°F) |

| Mounting Style | DIN Rail Mount (lightweight aluminum bracket) |

| Dimensions | 60mm (W) x 130mm (H) x 170mm (D) |

| Weight | 1.5kg (3.31 lbs) |

| Interface/Bus | ABB Standard Power Bus (compatible with ACS580/ACS380 Series) |

| Compliance | CE, UL, IEC 61800-5-1, RoHS |

| Supported Protocols | Modbus RTU, BACnet (via system integration) |

| Typical Power Draw | 4.5kW (max output); 0.8W (standby) |

5SHY2645L0004

The ABB 5SHY2645L0004 functions as a mid-range industrial power module engineered for integration with ABB’s versatile control systems, including the ACS580 and ACS380 VFD series—platforms widely used in medium-load automation. It converts incoming 3-phase AC power (380–480V AC, the industry standard for mid-scale operations) into stable DC power, delivering a maximum 4.5kW output to downstream equipment like packaging line conveyors, small robotic assembly arms, or batch mixer controllers. Positioned in the middle layer of the automation stack—between the main power supply and end-use devices—it acts as a buffer against voltage fluctuations, ensuring consistent power delivery even when the grid experiences minor spikes or dips.

5SHY2645L0004

Unlike one-size-fits-all modules, the ABB 5SHY2645L0004 is optimized for balanced loads: it avoids the energy inefficiency of high-power modules running at partial capacity and the overload risks of low-power units. It includes essential built-in protection features: dual-stage overcurrent protection, voltage surge suppression, and overtemperature shutdown, all activating in under 100ms to shield the module and connected equipment from damage. The module connects via ABB’s standard Power Bus interface, which leverages existing system wiring to simplify installation—no custom adapters or rewiring required. For systems needing basic redundancy (e.g., critical packaging lines), the ABB 5SHY2645L0004 can be paired with a second unit in a parallel setup, ensuring power continuity if one module fails.

Main features and advantages:

Choosing the ABB 5SHY2645L0004 delivers practical operational benefits, starting with cost and space efficiency. Its 4.5kW capacity is perfectly matched to medium-load applications—unlike high-power modules that consume excess energy when running below full capacity, the ABB 5SHY2645L0004 operates at 94% efficiency, reducing monthly energy costs for facilities like food processing plants that run 24/7. Its compact design (60mm width) also saves valuable rack space: in a typical packaging line control panel, replacing two low-power modules with one ABB 5SHY2645L0004 frees up 30% of available space, allowing for future expansions. For maintenance teams, the module’s integrated protection features cut down on troubleshooting time: instead of installing separate surge protectors or thermal sensors, the module’s built-in safeguards automatically handle issues like overcurrent or voltage spikes. For example, if a conveyor motor experiences a temporary overload, the module’s overcurrent protection triggers a soft shutdown—preventing damage to the motor and module—while sending an alert to the control system, so technicians can address the root cause without halting the entire line. This proactive protection minimizes unplanned downtime, a key priority for sectors like beverage manufacturing where production delays can lead to spoiled inventory.

Long-term reliability is another key advantage. Engineered for continuous mid-load operation, the ABB 5SHY2645L0004 uses durable components: high-grade capacitors rated for 8,000+ hours of use, dust-resistant vents, and corrosion-resistant terminals that withstand the moisture common in food processing environments. Unlike generic mid-range modules, it is fully validated for use with ABB’s ACS Series VFDs, eliminating compatibility issues that can cause intermittent power drops or equipment malfunctions. For engineers, this means consistency: they can trust that the module will integrate seamlessly with their existing ABB ecosystem and operate reliably for 5–7 years, reducing the need for frequent replacements or unplanned maintenance.

Application fields:

The ABB 5SHY2645L0004 is deployed across industries where balanced medium-load power is critical, starting with food and beverage processing. In a dairy plant, it powers ACS580 VFDs that control pasteurization line conveyors and mixing tanks—equipment that requires steady 4.0–4.5kW power to maintain precise temperatures and mixing speeds. The module’s voltage stabilization ensures consistent performance even when the plant’s refrigeration systems (which draw heavy power) cycle on, preventing pasteurization errors that could lead to product recalls.

Another key use case is packaging automation. In a e-commerce fulfillment center, the ABB 5SHY2645L0004 provides power to ACS380 VFDs controlling box-sealing robots and sorting conveyors. Its compact size fits easily into the center’s modular control panels, while its standby power draw (0.8W) reduces energy costs during off-peak hours. The module’s overtemperature protection is also critical here: fulfillment centers often have limited cooling, and the module’s ability to shut down safely if temperatures exceed 65°C prevents damage to expensive robotic components.

Finally, the module is widely used in pharmaceutical manufacturing, specifically in tablet press control systems. It powers the ACS580 VFDs that regulate press speed, ensuring consistent tablet weight and density. The ABB 5SHY2645L0004’s compliance with RoHS standards (no hazardous materials) aligns with pharmaceutical industry requirements for clean, non-toxic equipment, while its stable power delivery supports compliance with FDA regulations for process consistency.

Related products:

ABB 5SHY2645L0005– Higher-capacity (5.5kW) version of the 5SHY2645L0004 for medium-heavy loads (e.g., large mixers or heavy-duty conveyors).

ABB 5SHY2645L0003– Lower-capacity (3.5kW) model, ideal for light-medium loads like small packaging robots or lab-scale mixers.

ABB 5SHY2645L0008– Extended-temperature variant (-20°C to 70°C) of the 5SHY2645L0004, designed for cold storage facilities or warm manufacturing environments.

ABB 5SHY2645L0006– Isolated power module (compatible with 5SHY2645L0004) for systems requiring electrical isolation (e.g., pharmaceutical cleanrooms or medical device manufacturing).

ABB 5SHY2645L0010– Redundant power kit, including two 5SHY2645L0004 units and a basic redundancy controller for critical medium-load systems (e.g., pasteurization lines).

ABB 5SHY2645L0007– DC-input version (24–48V DC) of the 5SHY2645L0004 for off-grid applications (e.g., mobile packaging units or remote testing facilities).

ABB 5SHY2645L0012– Communication adapter, enabling the 5SHY2645L0004 to integrate with non-ABB control systems (e.g., Allen-Bradley Micro800 PLCs).

ABB 5SHY2645L0015– Heat sink accessory for the 5SHY2645L0004, extending its operating temperature range in warm environments (e.g., bakery production lines).

Installation and maintenance:

Before installing the ABB 5SHY2645L0004, verify that your ABB control system (e.g., ACS580 VFD) is running firmware version V2.8 or higher—older firmware may not fully support the module’s efficiency features or protection protocols. Ensure the installation location has adequate airflow: while the module operates at up to 65°C, prolonged exposure to temperatures above 60°C can shorten its lifespan, so avoid mounting it directly next to heat-generating components like power supplies or motor drives. In humid environments (e.g., dairy plants), check that the control panel is sealed to prevent moisture from entering the module’s vents—moisture can cause corrosion on terminals and lead to short circuits. Confirm input power compatibility: ensure the incoming AC power falls within the 380–480V range and that the circuit can handle the module’s max current draw (9.4A at 480V AC) to avoid overloading. For DIN rail installation, use a standard 35mm rail (minimum 1.0mm thickness)—the module’s lightweight design (1.5kg) doesn’t require reinforced mounting, simplifying setup.

Ongoing maintenance for the ABB 5SHY2645L0004 is straightforward but critical for consistent performance. Every two months, inspect the module’s LED status indicators: a solid green LED means normal operation, a blinking yellow LED signals a warning (e.g., high temperature or low input voltage), and a steady red LED indicates a critical fault (e.g., overcurrent or short circuit). If a fault occurs, refer to the module’s diagnostic manual—ABB’s online portal also has troubleshooting flowcharts to help pinpoint issues quickly. Never reset the module while the system is powered, as this can cause voltage spikes that damage connected equipment. Every three months, clean the module’s ventilation vents with a soft brush or low-pressure compressed air (20–30 PSI) to remove dust buildup—dust blocks airflow and increases the risk of overheating. Annually, perform a power output test using a calibrated load bank (capable of handling 4.5kW) to ensure the module is delivering full capacity; schedule this test during planned maintenance shutdowns to avoid disrupting production. Additionally, update the module’s firmware annually via ABB’s Industrial Software Suite to access the latest efficiency optimizations and protection features.

Other ABB product models:

REM615 panel

REM620 N-B-M-N-AA-AB-AB-B-1-B-N-1-XF

REM630E_C UBMNAAAAABBZAZNAX

RET316

RET-5211MRK001530-AE

RET541AB231AAAA

RET543AB243BAAA

RET543AM243AAAB

RET615F

RET620 NBTNAAAAABC1BNN11G

RET650

RET650 1KHL160055R0001A

RET670 1MRK002816-AC

RET670 1MRK002816-AC

RET670 1MRK002816-AB

RET670 1MRK002816-AC

RET670 1MRK002816-AC

RET670 in stock

REU610

REU610 CVVHCNR02

REU615B

REX521 GHHPSH07G

REX521GHHPSH50G

RF533 3BSE014227R1

RF615 3BHT100010R1

RHD250-10

RLM01

ABB S-073N 3BHB009884R5211

ABB S-093H 3BHB030478R0309

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626