Description

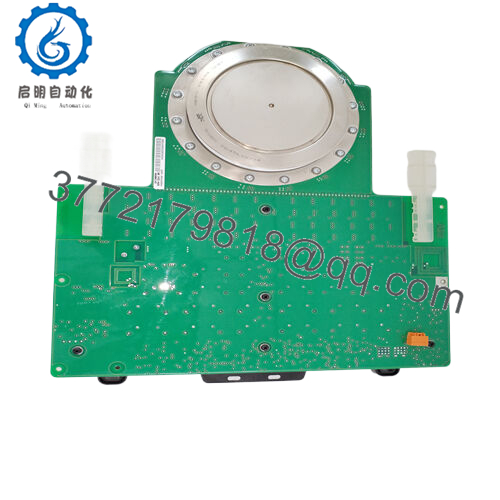

| Model Number | 5SHX2646L0004 |

| Brand | ABB |

| Type | High-Capacity Industrial Power Module (for High-Load VFD/Control Systems) |

| Input Voltage | 380–500V AC (3-phase) |

| Operating Temp Range | -25°C to 75°C (-13°F to 167°F) |

| Mounting Style | DIN Rail Mount (with reinforced bracket for stability) |

| Dimensions | 70mm (W) x 160mm (H) x 200mm (D) |

| Weight | 3.2kg (7.05 lbs) |

| Interface/Bus | ABB High-Power Bus (compatible with ACS880/ACS6080 Series) |

| Compliance | CE, UL, IEC 61800-5-1, ISO 12100 |

| Supported Protocols | Modbus RTU, PROFINET, Ethernet/IP (via system integration) |

| Typical Power Draw | 4.0kW (max output) |

5SHX2646L0004

The ABB 5SHX2646L0004 functions as a high-capacity industrial power module engineered to integrate seamlessly with ABB’s advanced control systems, particularly the ACS880 and ACS6080 VFD series—platforms commonly used in high-power industrial applications. It converts incoming 3-phase AC power into stable DC power, delivering consistent output to downstream high-load devices like large motors or robotic arms, and sits in the lower layer of the automation stack, between the main power supply and end-use equipment. Unlike standard power modules with limited capacity, the ABB 5SHX2646L0004 offers a robust 4.0kW max output and supports a wide input voltage range (380–500V AC), giving engineers the flexibility to deploy it in diverse industrial settings—from large manufacturing plants to heavy machinery operations—without needing custom power solutions.

5SHX2646L0004

It also includes enhanced built-in protection features, such as dual-stage overcurrent protection, voltage surge suppression, and overtemperature shutdown, which activate rapidly to prevent damage to the module and connected equipment, reducing the time and cost of post-failure troubleshooting. The module connects via ABB’s proprietary High-Power Bus interface, which leverages existing system wiring to simplify integration; it requires minimal external components, lowering the risk of wiring errors and speeding up installation. For systems requiring maximum uptime, the ABB 5SHX2646L0004 can be configured in parallel with additional modules to create a redundant power setup, ensuring continuous power delivery even if one unit experiences a fault.

Main features and advantages:

Choosing the ABB 5SHX2646L0004 delivers substantial operational benefits, starting with simplified high-load system design. Its 4.0kW capacity eliminates the need to daisy-chain multiple low-capacity modules to power heavy equipment, reducing rack space usage by up to 40% compared to multi-module setups—critical for industrial control panels where space is often limited. The module’s enhanced protection features are a major asset for maintenance teams: instead of installing separate surge protectors, current limiters, or thermal sensors, the ABB 5SHX2646L0004’s integrated safeguards handle these functions automatically, allowing technicians to focus on proactive maintenance (like routine inspections) rather than reactive repairs. This minimizes unplanned downtime—a top priority in industries like heavy manufacturing or mining, where a single hour of halted operations can result in tens of thousands of dollars in lost revenue.

Long-term durability is another key advantage. Engineered for heavy-duty industrial use, the ABB 5SHX2646L0004 uses high-grade components, including reinforced circuit boards and heat-resistant capacitors, that resist wear from continuous high-load operation and extreme environmental conditions—such as dust, vibration, or temperature swings. Unlike generic high-power modules, it is fully validated for use with ABB’s ACS Series high-load VFDs and control systems, eliminating compatibility issues that can cause power inconsistencies or equipment damage. For engineers, this means confidence: they can trust that the module will integrate seamlessly with their existing ABB ecosystem and operate reliably for years, reducing the need for costly replacements or system overhauls.

Application fields:

The ABB 5SHX2646L0004 is deployed across industries where high-load power reliability is critical, starting with heavy manufacturing. In automotive stamping plants, it powers large VFDs that control hydraulic presses—equipment that requires consistent 4.0kW power to shape metal sheets without defects. The module’s wide input voltage range (380–500V AC) ensures it operates smoothly even when the plant’s main power supply fluctuates (a common issue during peak production hours), supporting uninterrupted press operation and consistent part quality.

Another key use case is mining, specifically in underground coal or mineral mines. Here, the ABB 5SHX2646L0004 provides stable power to the control systems of large conveyor belts and drilling machinery, which require high power to move heavy loads or penetrate rock. Its ability to operate in extreme temperatures (-25°C to 75°C) and resist dust makes it ideal for underground environments, where standard power modules would fail due to harsh conditions.

Finally, the module is widely used in renewable energy, particularly in large-scale solar farms. It powers the control systems of utility-scale inverters, which convert DC power from solar panels into AC power for the grid. The ABB 5SHX2646L0004’s surge protection features prevent damage from voltage spikes caused by sudden sunlight changes, ensuring continuous inverter operation and maximizing energy production.

Related products:

ABB 5SHX2646L0005– Higher-capacity (5.0kW) version of the 5SHX2646L0004 for ultra-high-load applications (e.g., large industrial compressors).

ABB 5SHX2646L0003– Lower-capacity (3.0kW) model, ideal for medium-load systems like packaging line motors or small robotic arms.

ABB 5SHX2646L0008– Extended-temperature variant (-30°C to 80°C) of the 5SHX2646L0004, designed for polar mining operations or desert solar farms.

ABB 5SHX2646L0006– Isolated power module (compatible with 5SHX2646L0004) for systems requiring electrical isolation to prevent ground loops (e.g., medical-grade industrial equipment).

ABB 5SHX2646L0009– Redundant power kit, including two 5SHX2646L0004 units and a redundancy controller for critical systems like nuclear power plant control rooms.

ABB 5SHX2646L0012– DC-input version (48–110V DC) of the 5SHX2646L0004 for off-grid applications (e.g., remote mining sites or mobile industrial equipment).

ABB 5SHX2646L0015– Add-on heat sink module for the 5SHX2646L0004, used in high-temperature environments (e.g., steel mills) to further extend module lifespan.

ABB 5SHX2646L0018– Communication adapter module, enabling the 5SHX2646L0004 to integrate with non-ABB control systems (e.g., Siemens S7-1500 PLCs).

Installation and maintenance:

Before installing the ABB 5SHX2646L0004, verify that your ABB control system (e.g., ACS880 VFD) is running firmware version V3.0 or higher—older firmware may not fully support the module’s high-capacity output or advanced protection features. Ensure the installation location has adequate airflow: while the module operates at up to 75°C, prolonged exposure to temperatures above 65°C can reduce its lifespan, so avoid mounting it directly above heat-generating components like resistors, transformers, or other high-power modules. Check input power compatibility: confirm that the incoming AC power is within the 380–500V range and that the circuit can handle the module’s max current draw (8A at 500V AC) to prevent overloading. Also, inspect the DIN rail for stability—due to the module’s 3.2kg weight, use a reinforced DIN rail (minimum 1.5mm thickness) to prevent sagging or damage to the module’s connectors.

Ongoing maintenance is straightforward but critical to ensure long-term performance. Monthly, inspect the module’s LED status indicators: a solid green LED indicates normal operation, a blinking yellow LED signals a warning (e.g., high temperature or low input voltage), and a steady red LED means a critical fault (e.g., overcurrent or short circuit). If a fault occurs, refer to the module’s diagnostic manual to identify the cause—never reset the module while the system is powered, as this can cause voltage spikes that damage connected equipment. Every two months, clean the module’s ventilation grilles and heat sinks with compressed air (at 30–50 PSI) to remove dust buildup, which can block airflow and cause overheating. Annually, perform a power output test using a calibrated load bank (capable of handling 4.0kW) to ensure the module is delivering full capacity; ABB recommends using their High-Power Module Test Tool (HPMTT) for this process, as it provides detailed data on output stability and protection feature responsiveness for compliance records.

Other ABB product models:

REM615 panel

REM620 N-B-M-N-AA-AB-AB-B-1-B-N-1-XF

REM630E_C UBMNAAAAABBZAZNAX

RET316

RET-5211MRK001530-AE

RET541AB231AAAA

RET543AB243BAAA

RET543AM243AAAB

RET615F

RET620 NBTNAAAAABC1BNN11G

RET650

RET650 1KHL160055R0001A

RET670 1MRK002816-AC

RET670 1MRK002816-AC

RET670 1MRK002816-AB

RET670 1MRK002816-AC

RET670 1MRK002816-AC

RET670 in stock

REU610

REU610 CVVHCNR02

REU615B

REX521 GHHPSH07G

REX521GHHPSH50G

RF533 3BSE014227R1

RF615 3BHT100010R1

RHD250-10

RLM01

ABB S-073N 3BHB009884R5211

ABB S-093H 3BHB030478R0309

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626