Description

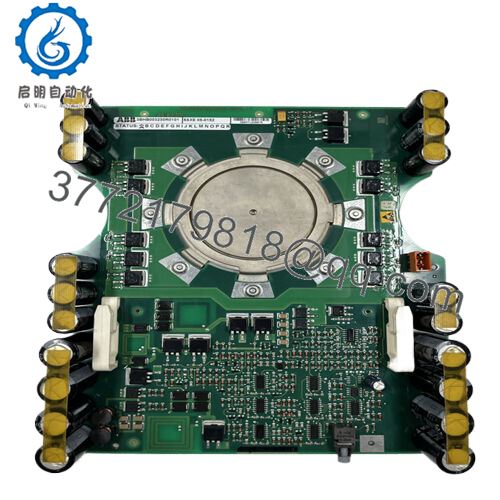

| Model Number | 5SHX1445H0001 |

| Brand | ABB |

| Type | Ultra-High-Current High-Voltage IGBT Module (Half-Bridge Configuration) |

| Input Voltage | Up to 4500 V DC |

| Operating Temp Range | -40 °C to +150 °C (-40 °F to +302 °F) |

| Mounting Style | Bolt-Mounted (Heavy-Duty Baseplate for Industrial Heat Sinks) |

| Dimensions | 250 mm (W) x 150 mm (H) x 55 mm (D) |

| Weight | 2.5 kg |

| Interface/Bus | High-Current Terminal Connections (Tinned Cu Alloy) |

| Compliance | CE, UL, IEC 60747-9, IEC 61287-1, DNV GL (Marine) |

| Supported Protocols | Compatible with ABB DriveCom, IEC 61850, MODBUS TCP (via external controllers) |

| Typical Power Loss | 0.65 W/A (at rated current, 1400 A) |

5SHX1445H0001

The ABB 5SHX1445H0001 acts as the backbone of ultra-high-power industrial systems, leveraging advanced IGBT technology to precisely regulate and switch electrical current—enabling seamless AC-DC/DC-AC conversion and voltage stabilization for heavy-duty equipment. It integrates seamlessly into ABB’s high-power ecosystem, pairing with ABB’s ACS680 ultra-high-power drives, PCS6000 grid-scale inverters, and marine propulsion converters. Unlike standard high-current modules, it uses ABB’s third-generation trench-gate IGBT chips with optimized carrier distribution, which reduces switching losses by up to 25% compared to older-generation modules.

5SHX1445H0001

This not only cuts energy waste but also minimizes heat output, a critical factor for systems operating at 1400 A continuous current. The module’s packaging is engineered for durability: a thick ceramic-insulated baseplate provides exceptional electrical isolation (critical for 4500 V DC operation) while maximizing heat transfer to industrial-grade heat sinks, even in environments with limited airflow (like marine engine rooms). Additionally, it supports full integration with ABB’s Ability™ Power Platform, allowing real-time monitoring of junction temperature, current spikes, and voltage stability—enabling engineers to detect potential issues before they lead to unplanned shutdowns.

Main features and advantages:

Choosing the ABB 5SHX1445H0001 delivers long-term value that extends far beyond basic power switching. It’s built to withstand the harshest industrial conditions: its housing resists vibration (up to 60 Hz), extreme thermal cycling (from -40 °C to +150 °C), and exposure to industrial contaminants (oil, dust, salt spray for marine use). This ruggedness reduces replacement frequency—extending the module’s lifespan to 8–10 years in typical operation, lowering total cost of ownership. The module’s ultra-high current rating (1400 A) eliminates the need for parallel module configurations (a common workaround for lower-current units), which simplifies system design, reduces wiring complexity, and cuts engineering time by up to 30%. Its low power loss translates to significant energy savings: in a 12 MW steel mill drive, the ABB 5SHX1445H0001 can reduce annual energy consumption by up to 12% compared to older modules, saving over $50,000 in energy costs per year. Moreover, its compatibility with existing ABB high-power systems means retrofits require minimal hardware changes—avoiding the expense of replacing entire drive or converter assemblies.

Application fields:

The ABB 5SHX1445H0001 excels in ultra-high-power applications across heavy industries and critical infrastructure. In steel manufacturing, it’s the core component of medium-voltage drives for hot rolling mills, handling the 1400 A current needed to power large motors that control roll speed—ensuring consistent metal thickness and reducing product waste. In marine propulsion, it’s integrated into the converters of large cargo ships and offshore support vessels, switching high current to electric propulsion motors while withstanding salt spray and vibration—improving fuel efficiency compared to diesel-only systems. In grid infrastructure, it’s used in large-scale reactive power compensators, stabilizing voltage during peak demand (e.g., summer air conditioning loads) and preventing grid fluctuations that could disrupt sensitive equipment. In all these environments, the module’s ability to operate at extreme temperatures and handle voltage spikes up to 6000 V ensures 99.9% system uptime—critical for applications where even a 30-minute outage can result in six-figure losses.

Related products:

ABB 5SHX1645H0001– Higher current rating (1600 A) for ultra-heavy applications like 15+ MW industrial compressors.

ABB 5SHX1465H0001– Higher voltage tolerance (6500 V DC) for grid-scale converters in high-voltage transmission systems.

ABB 5SHX1445H0002– Enhanced marine-grade version (IP65-rated terminals) for offshore wind turbine converters.

ABB 5SHX1445H0003– Fast-switching variant (10 kHz switching frequency) for high-power UPS systems in data centers.

ABB 5SHX1445H0004– Low-profile design (45 mm depth) for space-constrained applications like locomotive traction converters.

ABB 5SHX1445H0005– Extended-temperature model (-50 °C to +160 °C) for arctic oil rig power systems.

ABB 5SHX1245H0001– Lower current rating (1200 A) for cost-sensitive medium-power applications like large water pumps.

Installation and maintenance:

Before installing the ABB 5SHX1445H0001, verify that your system’s voltage (max 4500 V DC) and current (max 1400 A) ratings match the module’s specs—overloading can cause irreversible damage. Prepare the industrial heat sink by cleaning its surface with a non-abrasive cloth and isopropyl alcohol; any debris will increase thermal resistance, so ensure a smooth, clean contact area. Use a torque wrench to fasten the module’s mounting bolts to ABB’s recommended 20 N·m—under-tightening leads to poor heat transfer, while over-tightening can crack the baseplate. Update the system’s control software (e.g., ABB Ability™ Power Platform) to the latest firmware to unlock full diagnostic features, such as current spike alerts.

For maintenance, inspect terminal connections every 3 months—look for signs of overheating (discolored insulation) or loose bolts, which can cause arcing. Monitor junction temperature via the control system; if it exceeds 140 °C, check the heat sink’s cooling fans or water cooling loop (if used) for blockages. Perform a yearly insulation resistance test with a 2500 V megohmmeter to ensure the module’s isolation remains intact (minimum 100 MΩ resistance required).

Other ABB product models:

REM615 panel

REM620 N-B-M-N-AA-AB-AB-B-1-B-N-1-XF

REM630E_C UBMNAAAAABBZAZNAX

RET316

RET-5211MRK001530-AE

RET541AB231AAAA

RET543AB243BAAA

RET543AM243AAAB

RET615F

RET620 NBTNAAAAABC1BNN11G

RET650

RET650 1KHL160055R0001A

RET670 1MRK002816-AC

RET670 1MRK002816-AC

RET670 1MRK002816-AB

RET670 1MRK002816-AC

RET670 1MRK002816-AC

RET670 in stock

REU610

REU610 CVVHCNR02

REU615B

REX521 GHHPSH07G

REX521GHHPSH50G

RF533 3BSE014227R1

RF615 3BHT100010R1

RHD250-10

RLM01

ABB S-073N 3BHB009884R5211

ABB S-093H 3BHB030478R0309

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626