Description

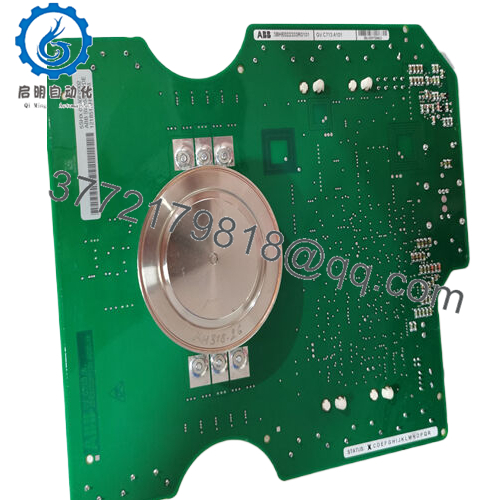

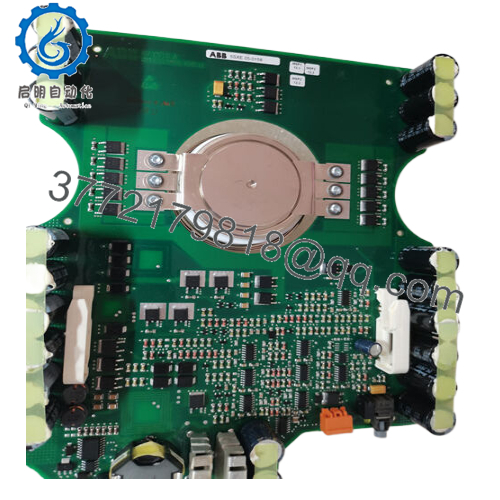

| Model Number | 5SHX0660F0002 |

| Brand | ABB |

| Type | High-Voltage IGBT Module (Half-Bridge Configuration) |

| Input Voltage | Up to 6500 V DC |

| Operating Temp Range | -40 °C to +150 °C (-40 °F to +302 °F) |

| Mounting Style | Screw-Mounted (Baseplate for Heat Sink Integration) |

| Dimensions | 190 mm (W) x 110 mm (H) x 45 mm (D) |

| Weight | 1.2 kg |

| Interface/Bus | High-Voltage Terminal Connections (Cu Alloy) |

| Compliance | CE, UL, IEC 60747-9, IEC 61287-1 |

| Supported Protocols | Compatible with ABB DriveCom, IEC 61850 (via external control units) |

| Typical Power Loss | 0.8 W/A (at rated current, 600 A) |

5SHX0660F0002

The ABB 5SHX0660F0002 acts as a core switching component in high-voltage industrial power systems, leveraging IGBT technology to control the flow of electrical power with precision—enabling smooth conversion between AC and DC, or voltage regulation for sensitive equipment. It integrates seamlessly into ABB’s medium-voltage ecosystem, pairing with ABB’s ACS6080 medium-voltage drives, PCS6000 energy storage inverters, and traction converters for rail and marine applications. Unlike basic IGBT modules, it uses ABB’s advanced trench-gate IGBT chip design to minimize switching losses by up to 15% compared to older planar-gate modules—directly boosting system efficiency and reducing heat generation.

5SHX0660F0002

It also features a robust packaging design: a ceramic-insulated baseplate provides excellent electrical isolation (critical for high-voltage safety) while ensuring efficient heat transfer to external heat sinks, even under continuous full-load operation (up to 600 A). The module supports ABB’s integrated monitoring solutions, such as the ABB Ability™ Power Platform, which enables real-time tracking of key parameters like junction temperature, current, and voltage—allowing engineers to detect anomalies early and avoid unplanned downtime.

Main features and advantages:

Choosing the ABB 5SHX0660F0002 delivers long-term value that extends far beyond basic power switching. It’s engineered for durability in harsh industrial settings, with a rugged housing that resists vibration (up to 50 Hz), thermal cycling (from -40 °C to +150 °C), and exposure to industrial contaminants like dust and oil—significantly reducing the need for premature replacements and lowering total cost of ownership. The module’s high voltage rating (6500 V DC) and current capacity (600 A) make it versatile, eliminating the need to source multiple modules for different high-voltage applications—simplifying inventory management and cutting engineering time spent on system design. Its low switching losses translate to tangible energy savings: in a large-scale water treatment plant using ABB ACS6080 drives, the ABB 5SHX0660F0002 can reduce annual energy consumption by up to 8% compared to less efficient IGBT modules, translating to thousands of dollars in cost savings. Additionally, its compatibility with ABB’s existing medium-voltage systems means minimal retrofitting is required when upgrading—avoiding the expense of replacing entire control architectures.

Application fields:

The ABB 5SHX0660F0002 excels in high-voltage, high-reliability applications across multiple industries. In grid infrastructure, it’s used in utility-scale energy storage systems, where it switches high-voltage DC (HVDC) power between batteries and the grid—ensuring stable power flow and supporting grid frequency regulation. In heavy industry, it’s a critical component in medium-voltage drives for cement kilns and steel rolling mills, handling high current loads to control motor speed with precision—directly improving production efficiency and reducing wear on mechanical components. In rail and marine traction, it’s integrated into locomotive and ship converters, converting AC power from overhead lines or generators to DC for traction motors—withstanding the vibration and temperature fluctuations of mobile operations. In all these environments, the module’s ability to operate at extreme temperatures (-40 °C to +150 °C) and handle voltage spikes up to 8000 V ensures critical system uptime, even in the most challenging conditions.

Related products:

ABB 5SHX0860F0002– Higher current rating (800 A) for more demanding high-voltage applications (e.g., large industrial drives).

ABB 5SHX0645F0002– Lower voltage tolerance (4500 V DC) for cost-sensitive medium-voltage systems (e.g., small-scale energy storage).

ABB 5SHX0660F0003– Enhanced-isolation version for systems with strict safety requirements (e.g., nuclear power auxiliary drives).

ABB 5SHX0660F0001– Older generation module; compatible with legacy ABB drives but lacks advanced trench-gate IGBT technology.

ABB 5SHX0660F0004– Fast-switching variant for high-frequency applications (e.g., grid-tied inverters with rapid response needs).

ABB 5SHX0660F0005– Compact design (160 mm x 90 mm) for space-constrained systems (e.g., marine traction converters).

ABB 5SHX0660F0006– Extended-temperature model (-50 °C to +160 °C) for extreme environments (e.g., arctic oil rig power systems).

Installation and maintenance:

Before installing the ABB 5SHX0660F0002, verify compatibility with your existing high-voltage system: confirm that the drive, inverter, or converter’s voltage and current ratings match the module’s specs (6500 V DC, 600 A) to avoid overloads. Prepare the heat sink by cleaning its surface with a lint-free cloth and isopropyl alcohol—any debris will increase thermal resistance, leading to overheating. Torque the mounting screws to ABB’s recommended 12 N·m to ensure optimal thermal contact between the module and heat sink; use a torque wrench to avoid under-tightening (which causes poor heat transfer) or over-tightening (which damages the module’s baseplate). Update the system’s control software (e.g., ABB Ability™ Power Platform) to the latest version to access full diagnostic features.

For ongoing maintenance, inspect the module’s terminal connections quarterly—look for signs of corrosion or loosening, which can cause arcing and module failure. Monitor junction temperature via the control software; if values exceed 130 °C, check the heat sink’s cooling fan (if used) and clean any accumulated dust. Perform a yearly insulation resistance test using a 2500 V megohmmeter to ensure the module’s electrical isolation remains intact.

Other ABB product models:

REM615 panel

REM620 N-B-M-N-AA-AB-AB-B-1-B-N-1-XF

REM630E_C UBMNAAAAABBZAZNAX

RET316

RET-5211MRK001530-AE

RET541AB231AAAA

RET543AB243BAAA

RET543AM243AAAB

RET615F

RET620 NBTNAAAAABC1BNN11G

RET650

RET650 1KHL160055R0001A

RET670 1MRK002816-AC

RET670 1MRK002816-AC

RET670 1MRK002816-AB

RET670 1MRK002816-AC

RET670 1MRK002816-AC

RET670 in stock

REU610

REU610 CVVHCNR02

REU615B

REX521 GHHPSH07G

REX521GHHPSH50G

RF533 3BSE014227R1

RF615 3BHT100010R1

RHD250-10

RLM01

ABB S-073N 3BHB009884R5211

ABB S-093H 3BHB030478R0309

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626