Description

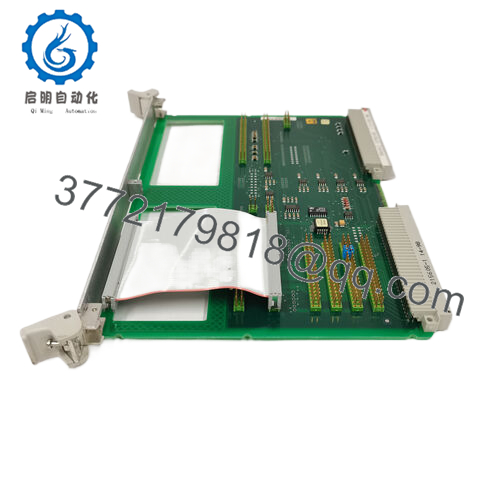

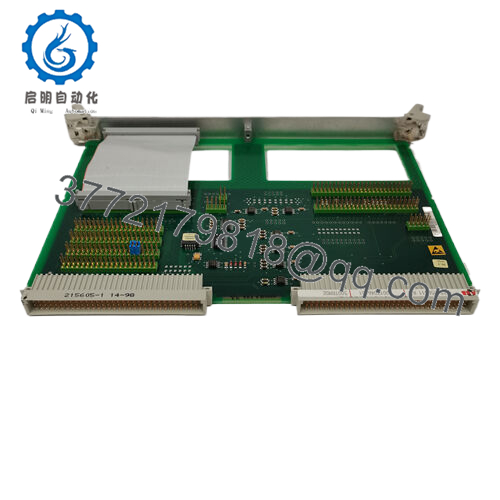

ABB 500TRM02 1MRB150011R1 is a high-performance communication module. It serves as an interface between different components within industrial automation systems, facilitating smooth data exchange. This module is designed specifically for use with ABB’s AC500 eco series, but also has flexibility to integrate with various other control platforms.

500TRM02 1MRB150011R1

It is connected to sensors (which may monitor parameters such as temperature, pressure, or flow) and transmits data to a central control unit, such as a programmable logic controller (PLC). On the other hand, it receives control signals from PLC and transmits them to actuators (such as motors or valves) to regulate industrial processes. This module supports multiple communication protocols, including Ethernet and RS485, which are commonly used in industrial environments. This multi protocol support enables it to communicate with various devices, regardless of their brand or model, as long as these devices follow these standard protocols.

500TRM02 1MRB150011R1

Main features and advantages:

It will continuously monitor the status of communication channels and connected devices. If any issues are detected, such as connection interruptions or device failures, it will sound an alarm to the control system, allowing engineers to take immediate corrective measures. This proactive monitoring method for system health helps reduce downtime and ensure the continuous operation of industrial processes.

ABB 500TRM02 1MRB150011R1 is designed to be reliable and ensure long-term performance in the harshest industrial environments. Its sturdy structure enables it to withstand high levels of electromagnetic interference, vibration, and temperature fluctuations, which are common in industrial factories. This means that it can operate continuously without frequent malfunctions, thereby reducing maintenance costs and improving overall production efficiency.

The high-speed data transmission capability of this module significantly improves the efficiency of industrial processes. For example, in high-speed production lines, fast data transmission can enable real-time decision-making. If the sensor detects a defect in the product, 500TRM02 1MRB150011R1 can quickly send this information to the control system, and then the system can take immediate action, such as transferring the defective product or adjusting the production process. This real-time response helps reduce waste and improve product quality.

Another major advantage of 500TRM02 1MRB150011R1 is its ease of integration. It can be easily integrated into existing industrial automation systems without the need for large-scale redesigns. This not only saves installation time, but also reduces the risk of errors during the integration process. In addition, its diagnostic function simplifies maintenance work. Being able to quickly identify and solve problems can reduce downtime and ensure smooth operation of industrial processes.

500TRM02 1MRB150011R1

Technical specifications:

Model 500TRM02 1MRB150011R1

Brand ABB

Type communication module

The installation method is suitable for standard DIN rail installation in industrial control cabinets

Interface/Bus Ethernet, RS485 (for communication with other devices)

contact us

Phone:+86 16626708626

WhatsApp/WeChat:+86 16626708626

Email: 3772179818@qq.com

500TRM02 1MRB150011R1

Application areas:

In automobile manufacturing factories, it is used to manage a complex network of sensors and actuators on the production line. It enables robotic arms, conveyors, and other automated equipment to operate seamlessly. For example, it ensures that the robotic arm can accurately grasp and place parts by accurately transmitting sensor position data to the control system.

In the power generation industry, it plays a crucial role in power plants. It monitors and controls the operation of turbines, generators, and power distribution systems. For example, in thermal power plants, this module helps to regulate the fuel supply of boilers according to load demand. It receives data from sensors monitoring power output, steam pressure, and temperature, and then sends control signals to fuel valves to adjust fuel flow accordingly.

It is also widely used in the food and beverage industry. In large-scale food production facilities, the 500TRM02 1MRB150011R1 ensures the smooth operation of the packaging machine. It coordinates the movement of packaging materials, product filling, and packaging sealing by communicating with various sensors and actuators involved in the packaging process.

500TRM02 1MRB150011R1

Related products:

ABB 500TRM03: Upgraded data processing capabilities for more complex industrial applications that require rapid processing and transmission of large amounts of data.

ABB 500TRM01: Still provides reliable communication, but with slightly reduced functionality. Suitable for small industrial facilities with limited budgets.

ABB 500TRM02- EX: Designed specifically for hazardous environments such as chemical plants or refineries, where there is a risk of explosion caused by flammable gases or dust.

ABB 500TRM02- RTU: Optimized for remote terminal unit applications with improved communication capabilities, suitable for applications that require remote monitoring and control of industrial processes from a remote location.

ABB 500TRM02- Compact: Designed to be more compact, suitable for installations with limited space. It provides the same functionality as the standard 500TRM02 1MRB150011R1 in a smaller form factor without compromising performance.

ABB 500TRM02- Redundancy: With enhanced redundancy capabilities, suitable for critical task applications. In certain medical or aerospace industries where continuous operation is crucial, this version provides additional reliability through redundant components.

ABB 500TRM02- High Speed: Designed specifically for applications that require extremely fast data transmission, such as high-speed data acquisition systems or real-time control systems in high-performance manufacturing processes.

Installation and maintenance:

Before installing ABB 500TRM02 1MRB150011R1, it is essential to verify the compatibility of the module with the existing control system. Check the communication protocol, voltage level, and physical dimensions to ensure proper installation. Ensure that the control cabinet has sufficient installation space and that the cooling system can handle the heat generated by the modules. In addition, ensure that the firmware of the module is up-to-date, as this can improve performance and address any known software issues.

For continuous maintenance, regularly check the LED status indicator lights on the module. These indicator lights can provide valuable information about the operating status of the module, such as power supply, communication, and error conditions. Regularly check the connectors to ensure they are secure and clean, as loose or corroded connectors may cause data transmission issues. It is recommended to conduct a comprehensive performance test once a year to ensure that the module continues to operate at its optimal level. This test should include checking data transmission speed, communication reliability, and overall system stability.

Other ABB product models:

ABB 745745

ABB 746376

ABB 07AC91

ABB 07KR31 FPR36000227R1202-O

ABB 07KT92

ABB 07KT92 GJR5250500R0202

ABB 07KT93

ABB 07KT93

ABB 07KT93 GJR5251300R0101

ABB 07KT94 GJR5252100R3261

ABB 07kt94g GJR5252100R0261

ABB 07KT94-S H3 GJR5252100R2201

ABB 07KT98 GJR5253100r0272

ABB 07KT98 GJR5253100R0272

ABB 07KT98 GJR5253100R0272

ABB 07MK92 GJR5253300R1161

ABB 086318-002

ABB 086329-004

ABB 086329-004

ABB 086329-004 includes SMI board (806339-001)

ABB 086339-501

ABB 086345-504

ABB 1KHL178016R0001F PSM03

ABB 1KHL178016R0001F PSM03

ABB 1KHL178016R0001F PSM03

ABB 1KHL178025R0102P COM02

ABB 1KHL178025R0102P COM02

ABB 1KHL178025R0102P COM02

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626