Description

In the demanding landscape of industrial automation, coordinating I/O signals across distributed field devices and central controllers frequently exposes vulnerabilities like latency in data exchange, signal corruption from noise, or bottlenecks in modular expansions that grind processes to a halt. Consider a food and beverage bottling line where sensors track fill levels and conveyor speeds—any hiccup in the I/O chain could misalign batches, spoiling product or triggering unsafe stops that ripple through the shift. Or think of a wastewater treatment plant, buried under layers of pumps and valves in a corrosive, vibration-riddled setup, where imprecise signal routing leads to overflow risks or inefficient chemical dosing, inflating compliance costs and operational headaches. These aren’t rare glitches; they’re the routine threats to system stability in process control environments, where high reliability hinges on unflinching data flow and seamless integration.

That’s the crux the ABB 500TRM02 1MRB150011R1 is built to resolve as a versatile coupler module in ABB’s AC500 series, acting as the linchpin for reliable I/O signal distribution in PLC architectures. It targets the engineer’s push for modular scalability and signal fidelity, ensuring field inputs—like thermocouple readings or discrete switches—translate cleanly to CPU directives without the drag of custom intermediaries. In setups demanding continuous uptime, such as assembly lines or utility substations, the ABB 500TRM02 1MRB150011R1 proves essential by supporting up to 64 downstream modules per bus, mitigating the sprawl of wiring runs that plague legacy systems. Its focus on anti-interference shielding and fast-response processing means you sidestep the frustration of intermittent faults, allowing tighter loops for predictive adjustments that keep yields steady.

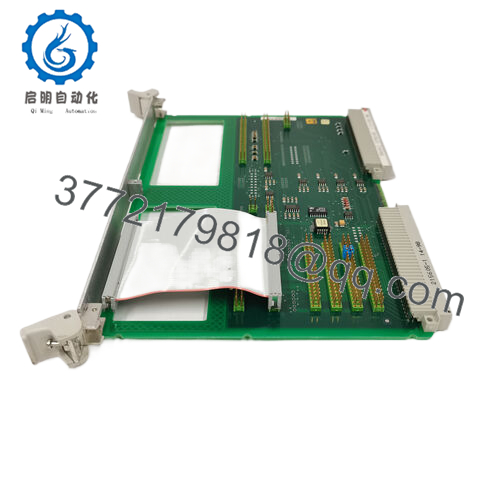

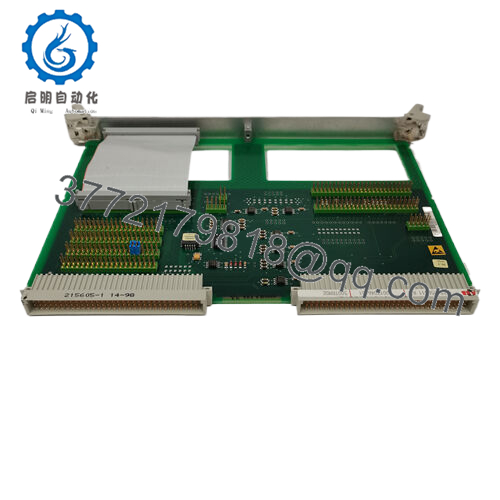

- 500TRM02 1MRB150011R1

Engineers appreciate how the ABB 500TRM02 1MRB150011R1 demystifies expansion in industrial automation without overcomplicating the stack—it’s the quiet enabler that lets you layer in analog or digital nodes incrementally, all while upholding the high reliability your safety audits demand. Whether retrofitting a dusty factory floor or greenfielding a remote monitoring outpost, it trims engineering hours on protocol mismatches, channeling clean I/O signals to foster responsive process control that aligns with evolving throughput goals. In short, it’s the module that turns potential chaos into controlled cadence.

The ABB 500TRM02 1MRB150011R1 functions as the backbone coupler in your AC500 PLC ecosystem, perched in the mid-tier of the automation stack to orchestrate signal traffic between remote I/O racks and the core CPU. It latches onto the system’s backplane via a standardized connector, fanning out fieldbus communications to handle inputs from sensors or outputs to effectors, converting raw analog voltages or digital states into protocol-wrapped packets that zip to the processor with minimal overhead. In a typical deployment, you’d slot it into a DIN-rail enclosure alongside power supplies and base units, where it governs data highways like PROFIBUS or Modbus, ensuring synchronized polling across nodes without collision risks.

What makes it click in real systems is its plug-and-play rapport with ABB’s Control Builder software—configure channel mappings once, and it auto-negotiates baud rates for downstream modules, embedding diagnostics like bus load metrics or fault counters that surface in your HMI for at-a-glance triage. Redundancy comes through dual-port options for ring topologies, dodging single-link failures in critical paths, while its galvanic isolation buffers against ground loops in noisy plants. Positioned as the gateway in distributed I/O architectures, the ABB 500TRM02 1MRB150011R1 thrives in hybrid setups, bridging legacy 24VDC discretes with Ethernet/IP overlays to ease migrations. No deep dives into custom firmware; it just keeps the signal pulse steady, empowering your loops to react in cycles under 10ms for those fast-paced sequences.

| Specification | Details |

|---|---|

| Model Number | 500TRM02 1MRB150011R1 |

| Brand | ABB |

| Type | Coupler Module |

| Input Voltage | 24 V DC ±10% |

| Operating Temp Range | -25°C to +60°C |

| Mounting Style | DIN Rail |

| Dimensions | 125 x 100 x 85 mm |

| Weight | 0.5 kg |

| Interface/Bus | PROFIBUS / Backplane |

| Compliance | CE, RoHS, IEC 61131 |

| Supported Protocols | Modbus RTU, PROFIBUS DP, Ethernet/IP |

| Typical Power Draw | 3 W |

Bringing the ABB 500TRM02 1MRB150011R1 into your fold means bolstering a setup where reliability isn’t gambled on but guaranteed through ruggedized paths that shrug off EMI spikes or thermal swings, yielding the performance consistency that turns erratic runs into predictable rhythms. In vibration-heavy zones like pump houses, its shock-tested build holds the line on signal purity, letting controllers make split-second calls on valve positions without the second-guessing that erodes trust in your data. This translates to fewer cascade failures, where one bad read doesn’t snowball into hours of debug, keeping your metrics on track for audits and bonuses alike.

The integration perks compound from there, dialing back engineering overhead by hot-swapping modules mid-cycle—pop in diagnostics mid-shift, and the bus reconfigures without a reboot, shaving response times on expansions from days to afternoons. Engineered for the grit of prolonged duty, the ABB 500TRM02 1MRB150011R1 weaves in self-monitoring that flags overloads early, morphing routine patrols into data-driven forecasts that stretch intervals between interventions. For teams chasing efficiency, it unlocks modular growth without cabinet overhauls, ensuring long-term performance that scales with your output ambitions while trimming the fat from support tickets and spare inventories.

In manufacturing assembly halls, the ABB 500TRM02 1MRB150011R1 routes discrete signals from proximity switches to orchestrate robotic arms, where fast data cycles demand sub-10ms latency to sync parts feeds—its bus mastery upholds critical system uptime amid conveyor jostles, folding into SCADA for oversight that nips jams in the bud. Water utilities deploy it in remote valve stations, coupling analog flow meters to central PLCs over rugged fieldbus; here, high reliability counters flood-prone dampness, enabling process control that optimizes dosing without on-site heroics.

Power distribution fits it snugly too, linking breaker status inputs in substations where vibration from transformers tests every joint—the module’s isolation ensures clean I/O signals for fault isolation, bolstering resilience in environments craving continuous uptime and regulatory nods.

500CPU03 1HDF700003R5122 – Core CPU companion for high-speed logic execution in AC500 backplanes.

500BIM01 1MRB150024R0002 – Binary input module for expanding discrete sensing in basic monitoring.

500AIM02 1MRB150022R001 – Analog input add-on for multi-channel process variable acquisition.

500DOM02 1MRB150023R0001 – Digital output extender, suited for actuator drives in sequence controls.

500PSM01 1MRB150021R0001 – Power supply unit for stable rack feeding alongside couplers.

TU516-H 1SAP215000R0001 – Terminal baseplate for secure field wiring in I/O expansions.

500MTM02 1MRB150020R1102 – Motor monitoring variant for thermal diagnostics in drive integrations.

When gearing up to rack the ABB 500TRM02 1MRB150011R1, first map your fieldbus topology against the AC500 guidelines—overloading a segment with more than 32 nodes risks throughput dips, so tally your I/O count and prune if needed. Scan for enclosure airflow too; with its modest heat output, it needs 25mm gaps above and below to stay under spec in stacked DIN setups, especially if ambient creeps past 50°C— a quick calc on your cabinet’s CFM will confirm. On the software side, sync firmware via ABB’s portal to your PLC revision, and dry-run a loopback test on the bench to vet address schemes before field ties.

Running it long-term calls for measured habits that pay off in uptime. Ping the front LEDs biweekly for bus health—steady green means harmony, but a flickering amber warrants a cable sweep for frays or corrosion. Every six months, torque down terminals to 0.5 Nm to counter settling from vibes, and log a full bus scan with Control Builder to baseline latency trends. In grimy spots, a soft-bristle vacuum quarterly keeps dust from vents without static risks, while an yearly firmware nudge ensures protocol tweaks don’t leave you exposed. These aren’t chores; they’re the tuned cadence that keeps your industrial automation lean and your interventions rare.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626