Description

In the sprawling domain of industrial automation, where remote sensors and actuators must relay data across vast distances without faltering to noise, power constraints, or network sprawl, engineers routinely battle the fallout from unreliable connectivity—think delayed alerts in a pipeline monitoring setup that let pressure anomalies fester into leaks, or fragmented I/O signals in a mining haulage system that misalign conveyor sequences, grinding operations to a halt amid dust-choked expanses. Or consider offshore wind farms, where turbine nodes scattered over kilometers face battery drain and interference from salt spray, compromising the real-time process control loops that dictate energy yields and grid stability. These aren’t isolated incidents; they’re the structural strains in distributed environments, where high reliability in wireless I/O signal paths is essential to sidestep the cascade of downtime, compliance violations, and retrofit expenses that plague legacy wired rigs.

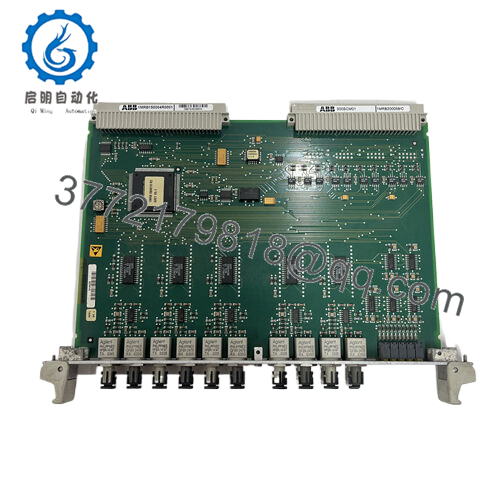

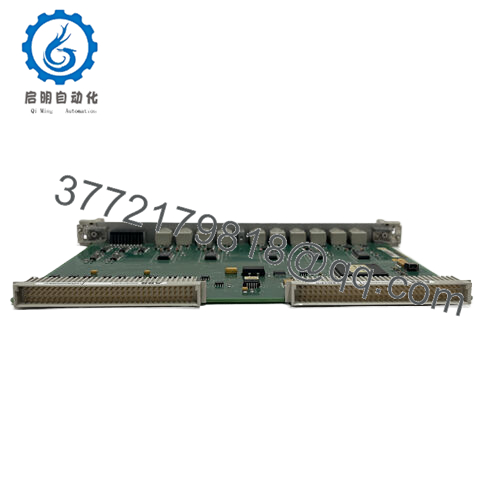

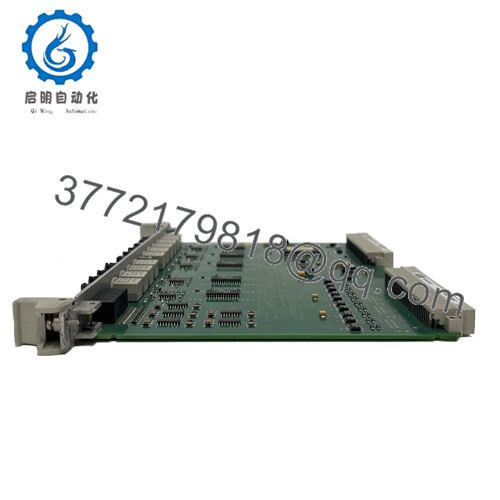

The ABB 500SCM01 1MRB200059C 1MRB15004R0001 rises to this as a wireless integrated coupler module in ABB’s AC500 ecosystem, purpose-built to extend connectivity horizons with mesh-network resilience. It zeros in on the engineer’s pursuit of flexible, low-overhead data bridging, harnessing serial ports and configurable I/O to tether remote devices—up to 600 meters in open air—into your PLC backbone, all while sipping just 4.5 watts in receive mode to stretch battery life in untethered nodes. In demanding deployments like asset tracking in logistics yards or environmental sensing in solar arrays, the ABB 500SCM01 1MRB200059C 1MRB15004R0001 becomes a linchpin, its multi-protocol stack (Modbus RTU to Ethernet/IP) fusing disparate endpoints without the wiring labyrinths that inflate installation costs. By embedding self-healing topologies and diagnostic beacons, it quells signal dropouts from RF clutter, ensuring process control remains agile and your engineering teams unburdened by constant link patrols.

The ABB 500SCM01 1MRB200059C 1MRB15004R0001 carves a niche in industrial automation through its blend of reach and restraint—it’s the module that scales without suffocating budgets, supporting up to 31 nodes per segment for sprawling I/O architectures, while its LCD diagnostics surface packet loss or hop counts to preempt blackspots. For outfits chasing IIoT infusions in brownfield sites, it dissolves the silos of wired holdouts, enabling over-the-air firmware pushes that evolve your network sans physical interventions. Ultimately, it forges process control that’s expansive yet economical, trimming the latency that undermines predictive maintenance and upholding the high reliability your stakeholders measure in uptime percentages.

- ABB 500SCM01 1MRB200059C 1MRB15004R0001

- ABB 500SCM01 1MRB200059C 1MRB15004R0001

The ABB 500SCM01 1MRB200059C 1MRB15004R0001 perches at the edge of your AC500 PLC stack, functioning as a mesh gateway that aggregates wireless node data into the central backplane for unified processing. It captures inputs from remote sensors—say, vibration thresholds or tank levels—via its ten configurable I/O ports (discrete/analog mix), serial RS232/485 for legacy tie-ins, and a 2.4 GHz radio for peer-to-peer relaying, then encapsulates them into Modbus or PROFIBUS frames that cascade to the CPU with sub-10ms latency. In a field cabinet, it docks to a DIN-rail base alongside power modules, forming a hybrid hub where wired locals mingle with airborne remotes, its embedded CPU juggling encryption and routing to dodge collisions in dense clusters.

System synergy flows naturally: integrate with S500 I/O slices for local expansion, and it’s auto-discovering nodes via ABB’s Automation Builder, with USB for on-site tweaks and Ethernet for SCADA uplinks that mirror health metrics like signal strength to your dashboard. Redundancy thrives in its ring-mesh design, rerouting around node failures in under a cycle, while onboard relays flag out-of-range drifts for proactive swaps. Leaning into distributed topologies—think sensor webs in rail yards—the ABB 500SCM01 1MRB200059C 1MRB15004R0001 bridges the gap from isolated endpoints to enterprise oversight, its low-power modes syncing with solar harvesters for off-grid endurance. For mixed fleets blending AC500 with third-party radios, its protocol agility curtails adapters, so you refine mesh parameters over mending meshes.

| Specification | Details |

|---|---|

| Model Number | 500SCM01 1MRB200059C 1MRB15004R0001 |

| Brand | ABB |

| Type | Wireless Coupler Module |

| Input Voltage | 24 V DC ±10% |

| Operating Temp Range | -40°C to +70°C |

| Mounting Style | DIN Rail |

| Dimensions | 125 x 100 x 85 mm |

| Weight | 0.37 kg |

| Interface/Bus | RS232/485, 2.4 GHz Radio |

| Compliance | CE, RoHS, IEC 61131 |

| Supported Protocols | Modbus RTU, PROFIBUS DP, Ethernet/IP |

| Typical Power Draw | 4.5 W (receive mode) |

Adopting the ABB 500SCM01 1MRB200059C 1MRB15004R0001 instills a wireless reliability that’s tuned for the sprawl of untamed sites, where its RF-hardened antennas and error-correcting codes preserve packet integrity amid multipath echoes or weather-induced fades, begetting performance consistency that steadies remote loops and averts the phantom reads that skew analytics. In battery-constrained outposts like remote valves, this means gateways that linger months on a charge, letting field crews chase optimizations over recharge treks—directly honing the responsiveness your throughput dashboards demand without the tether of buried cables.

The connectivity perks amplify in practice, lightening engineering overhead by self-provisioning nodes with a scan—deploy a dozen sensors, and it’s meshing them in minutes via app-guided pairing, while over-the-air logs distill RF trends for virtual audits that nix site visits. Engineered for the grit of perpetual vigilance, the ABB 500SCM01 1MRB200059C 1MRB15004R0001 cultivates maintenance through beacon pulses that herald battery sags, elongating patrols from weekly woes to seasonal sweeps and redirecting talent to algorithm upgrades. In the wider weave, it erects an automation scaffold that sprawls with your ambitions, where grafting edge AI onto mesh nodes elevates foresight without foundational fractures, anchoring long-term performance to fiscal flexibility and expansive reach.

In oilfield gathering stations, the ABB 500SCM01 1MRB200059C 1MRB15004R0001 webs pressure transmitters across lease lines, relaying flow variances for leak detection where long-range hops cut trenching costs—its low-draw efficiency ensures critical system uptime in process control terrains battered by remoteness, tying into SCADA for predictive valve strokes. Agricultural irrigation grids harness it for soil moisture nodes in vast fields, its mesh dodging crop interference to sustain high reliability amid variable terrain, enabling zoned watering that conserves resources without wired pitfalls.

Renewable solar farms round the profile, clustering panel inverters via the module’s I/O for yield tracking under erratic clouds—the radio’s redundancy upholds continuous uptime in distributed process control setups, feeding centralized PLCs for fault isolation that maximizes harvest in sun-scorched expanses.

500SCM02 1MRB200060C – Enhanced variant with extended range for ultra-remote sensor arrays.

500BIM01 1MRB150024R0002 – Binary input expander for discrete signals in wireless node clusters.

500AIM02 1MRB150022R001 – Analog input module to complement multi-parameter remote monitoring.

500DOM02 1MRB150023R0001 – Digital output companion for remote actuator commands over mesh.

500PSM01 1MRB150021R0001 – Power supply unit for stable feeding in hybrid wired/wireless racks.

TU516-H 1SAP215000R0001 – Terminal base for field wiring security in gateway enclosures.

500MTM02 1MRB150020R1102 – Motor telemetry add-on for vibration data in drive-linked nodes.

When staging the ABB 500SCM01 1MRB200059C 1MRB15004R0001 for DIN mounting, audit RF clearance first—obstructions within 1m can halve range, so site-survey with a spectrum analyzer against ABB’s channel maps to dodge interference bands. Factor enclosure IP too; for outdoor nods, pair with NEMA 4X housings to repel ingress, and tally node density to cap segments at 31—cross with your power profile, as loads over 5W in transmit spike draw. Firmware alignment wraps prep: fetch the mesh-optimized release from ABB’s depot, pair to your PLC build, and emulate a hop chain on a testbed to validate latency before broadcast.

In the operational flow, oversight tilts tactical and telemetry-led. Fortnightly app pings for hop metrics can unearth fringe weaknesses, spurring antenna tweaks before coverage craters. Semiannually, reseat antennas with dielectric compound against corrosion in coastal drifts, torquing to 0.3 Nm where winds whip. Cap with an annual firmware refresh: simulate traffic surges, recal if jitter climbs past 5ms, and hoard logs for decay traces like signal attenuation. These protocols mine the module’s diagnostics to sustain your industrial automation’s span, framing diligence as a drift net, not a drag.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626