Description

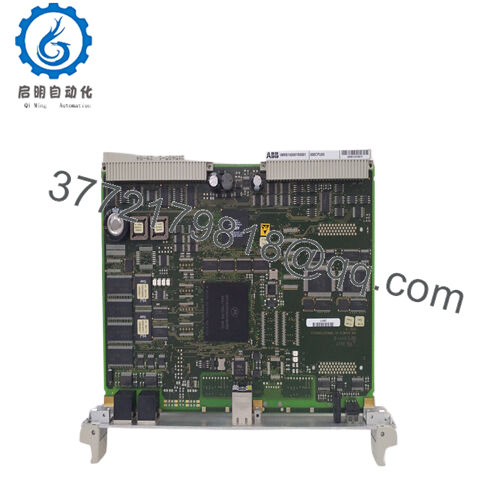

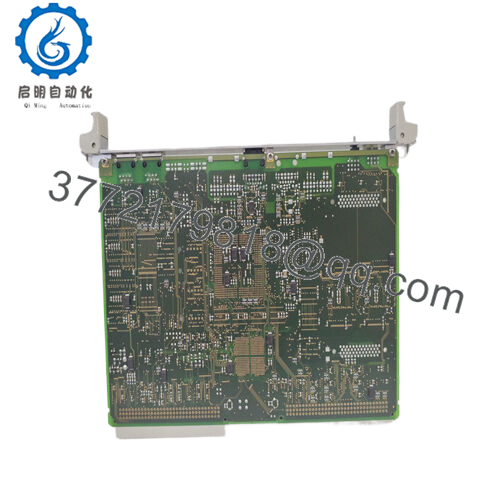

The ABB 500CPU05 is a high-performance programmable logic controller (PLC) CPU module designed specifically to meet the evolving demands of industrial automation systems. Industrial engineers and automation professionals often face challenges in managing increasingly complex control tasks, requiring rapid processing, extensive I/O handling, and seamless communication capabilities. The ABB 500CPU05 addresses these challenges by delivering reliable and scalable control performance that supports both small and large-scale applications. Its flexibility enables users to achieve system stability, reduce cycle times, and maintain high reliability—all essential for efficient process control and industrial automation environments.

| Specification | Details |

|---|---|

| Model Number | ABB 500CPU05 |

| Brand | ABB |

| CPU Type | 80196 at 10 MHz |

| Program Memory | 128 KB |

| I/O Capacity | Up to 256 points |

| Communication Ports | 1x Ethernet (10/100 Mbps), 2x RS232/485 |

| Power Supply | 24 V DC ±20% |

| Operating Temp Range | -25°C to +60°C |

| Dimensions | 115 mm x 90 mm x 70 mm |

| Weight | Approx. 0.5 kg |

500CPU05

500CPU05

How the Product Works & Fits into a System

The ABB 500CPU05 serves as the central processing unit within the ABB AC500 modular PLC family. It operates with an 80196 CPU at 10 MHz, sufficient for handling demanding control logic with cycle times measured in microseconds. The CPU supports up to 256 I/O points through modular extension and comes with multiple communication interfaces, including Ethernet and configurable RS232/RS485 ports. It integrates smoothly into control racks and communicates with external devices, field networks, and higher-level SCADA or MES systems using protocols like Modbus, PROFIBUS, and PROFINET. The CPU’s modular architecture allows flexible expansion with various certified I/O modules, making it adaptable to diverse automation needs. Its onboard diagnostics and user-friendly display facilitate fast troubleshooting and maintenance.

Real-World Benefits

The ABB 500CPU05 is engineered to provide industrial control applications with powerful processing and flexible communication, enabling rapid cycle times and stable operation even in complex scenarios. Its ability to handle a broad I/O range supports system scalability while reducing hardware footprint and engineering complexity. The multiple communication ports facilitate seamless data exchange with diverse field devices and networks, ensuring that process control remains transparent and reliable. Its robust design withstands harsh industrial environments, helping reduce downtime and maintenance. These features combine to deliver consistent performance and long-term reliability, key for industries demanding operational continuity.

Typical Use Cases

The ABB 500CPU05 is commonly used across manufacturing, water treatment, and energy production facilities. It is ideal for controlling assembly lines, pump stations, or power distribution tasks where precise timing, extensive I/O, and real-time data communication are critical. Its modular nature allows it to adapt to evolving automation demands, making it suitable for upgrading legacy systems or implementing new ones. The CPU’s capacity to support multiple industrial protocols ensures interoperability in heterogeneous control networks, reinforcing uptime and operational efficiency in process control environments.

Compatible or Alternative Products

500CPU10 – Higher memory and processing power for more demanding applications

PM572 – AC500 CPU with integrated serial communication ports

PM592-ETH – Ethernet-enabled CPU with increased program memory

3BSE032293R0001 – Analog input module for additional sensor integration

PM585-ETH – Extended CPU with PROFINET communication for Industry 4.0 connectivity

PM591-2ETH – CPU with dual Ethernet ports for segmentation and redundancy

PM595-4ETH-F – High capacity CPU with fault-tolerant communication

Setup Notes & Maintenance Insights

Before deploying the ABB 500CPU05, ensure the control rack provides sufficient space and proper 24 V DC power supply within tolerance limits. Configure communication interfaces—Ethernet and RS232/485—according to the integration requirements. Firmware updates should be applied regularly to leverage performance improvements and security fixes. Routine maintenance includes monitoring diagnostic LEDs, periodically inspecting electrical connections, and verifying program backups stored in onboard memory or SD cards. This proactive approach helps maintain reliable operation and prevents unexpected downtimes in critical control applications.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626