Description

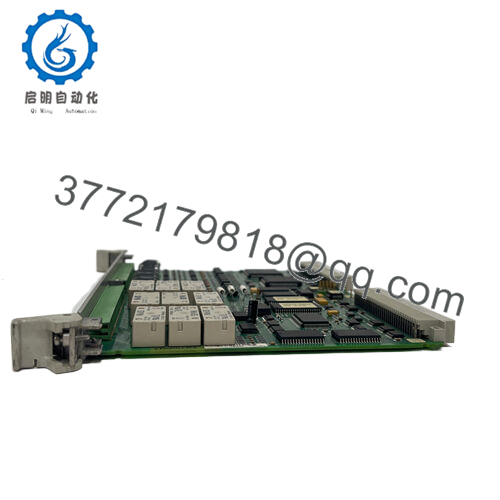

ABB 500BIO01 1MRB150005R1J is an important member of ABB’s industrial automation product family. It is compatible with ABB’s advanced automation control system architecture and plays a key role in signal acquisition, processing, and equipment control throughout the entire system.

500BIO01 1MRB150005R1J

By connecting with various sensors, actuators, and control systems, it integrates and analyzes various signals from the production site, outputs accurate control signals based on preset control strategies, and achieves comprehensive monitoring and precise control of industrial production processes. For engineers and system integrators, its advantages are significant. It has high compatibility and can easily integrate into existing or newly built automation systems, reducing the technical difficulty and cost investment of system upgrades and renovations. At the same time, flexible configuration and programming can be carried out according to the complex needs of different industrial scenarios, meeting diverse control logic and application scenarios, laying a solid foundation for building stable, efficient, and intelligent industrial automation control systems.

500BIO01 1MRB150005R1J

Main features and advantages:

From a functional performance perspective, ABB 500BIO01 1MRB150005R1J exhibits outstanding characteristics. It has high-speed data processing capability, which can quickly and accurately analyze and process a large number of input signals in a very short time, ensuring real-time response to changes in industrial processes and meeting the strict requirements of industrial automation for timely control. In the process of signal processing, advanced algorithms and technologies are adopted to effectively eliminate noise interference and ensure the accuracy and reliability of data. Faced with the complex and ever-changing industrial electromagnetic environment, this module is equipped with comprehensive electromagnetic shielding and anti-interference measures, which can effectively resist adverse factors such as power fluctuations and electromagnetic radiation, ensuring stable operation of equipment in harsh environments. Signal transmission and control instruction execution are not interfered with, avoiding equipment misoperation or production accidents caused by interference.

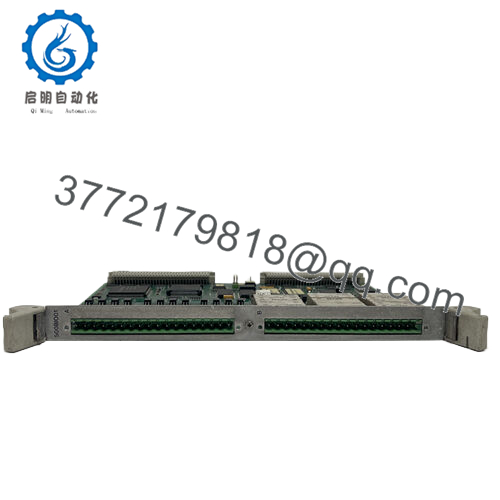

In terms of hardware design, the module is made of high-quality, sturdy and durable materials, with excellent mechanical strength and stability. It can withstand harsh conditions such as vibration, impact, high temperature, and high humidity in industrial environments, ensuring stable and reliable operation during long-term and high-intensity use. The compact and reasonable size design allows it to be flexibly installed in various control cabinets or equipment with limited space, saving valuable installation space. At the same time, a universal and easy to operate installation method is adopted, such as the common DIN rail installation, which facilitates quick installation and layout adjustment during later maintenance on site, improving the convenience of project implementation and maintenance.

Compatibility is one of the outstanding advantages of ABB 500BIO01 1MRB150005R1J. It supports communication protocols widely used in various industrial fields, such as Modbus, Profibus, and Ethernet communication protocols, and can seamlessly connect with sensors, actuators, and automation control systems of different brands and types, achieving interconnectivity of the entire automation system, breaking down communication barriers between devices, and facilitating the construction of large-scale and complex industrial automation control networks. This feature makes it play an important role in system integration in different industrial scenarios, enabling it to work in conjunction with existing automation equipment, reducing equipment replacement costs for enterprises, improving system integration efficiency, and helping enterprises quickly achieve industrial automation upgrades.

In terms of long-term reliability assurance, the module has been carefully designed and rigorously tested. Having an efficient heat dissipation structure, it can effectively dissipate the heat generated internally during long-term high load operation, maintain the appropriate working temperature of electronic components, thereby extending the service life of components and ensuring long-term stable operation of modules. And, before leaving the factory, it undergoes multiple strict quality inspection processes and aging tests to ensure the reliability and stability of the product in actual use from the source, reduce maintenance costs and equipment downtime, and provide reliable guarantees for the production and operation of the enterprise. Its built-in self diagnostic function can monitor its own operating status in real time. Once a hidden fault is detected, it will immediately issue an alarm and perform self repair or switch to standby mode, minimizing the impact on production.

500BIO01 1MRB150005R1J

Technical specifications:

Model 500BIO01 1MRB150005R1J

Brand ABB

Multi functional control and monitoring module of type

Adapt power supply to common industrial power specifications (depending on actual application scenarios)

Working temperature -20 ° C to+60 ° C

Installation method: DIN rail installation

The input signal type supports multiple industrial standard signals, including digital and analog signals, and can be adapted to various sensor outputs

Output load capacity meets the driving requirements of common industrial actuators

Communication interface RS-485, Ethernet, supports mainstream communication protocols such as Modbus

Certification complies with international authoritative certification standards such as CE and UL

Natural convection combined with efficient heat dissipation fins to assist in heat dissipation

Environmental grade IP20, can resist a certain degree of dust, suitable for general industrial environments

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

500BIO01 1MRB150005R1J

Application areas:

In intelligent warehousing and logistics systems, fast and accurate access to goods is crucial. ABB 500BIO01 1MRB150005R1J can be used for monitoring and controlling equipment such as automated shelves, stackers, and conveyor lines. By connecting various sensors such as cargo position sensors, weight sensors, etc., it can collect real-time equipment operation status and cargo information. When goods need to be stored, this module receives sensor signals, determines the available space on the shelves, and controls the stacker crane to accurately place the goods in the designated location; When the goods are released from the warehouse, it precisely controls the conveyor line to quickly transport the goods to the shipping area based on the order information. Once there is an abnormality in the system, such as a blockage in the conveyor line or a malfunction in the stacker crane, ABB 500BIO01 1MRB150005R1J can quickly detect it and control the relevant equipment to stop running. At the same time, an alarm is issued to notify the staff, effectively avoiding damage to the goods and system paralysis, ensuring efficient and stable storage flow operations.

In the automotive parts manufacturing workshop, the production process is highly automated, requiring extremely high precision control and stability of equipment. ABB500BIO01 1MRB150005R1J can be used to control precision machining equipment such as CNC machines, stamping machines, etc. It is connected to the control system of the device, receiving instructions from the operating terminal and signals feedback from the device’s own sensors, such as tool position sensors, pressure sensors, etc. When machining parts on CNC machine tools, this module precisely controls the motor speed and tool feed rate according to the preset machining program, ensuring machining accuracy reaches the micrometer level. When the stamping machine performs stamping operations, it can adjust the stamping pressure in real time according to the material and thickness of the sheet metal, ensuring stable quality of the stamped parts. If there is any abnormality during the operation of the equipment, such as excessive tool wear or abnormal stamping pressure, ABB 500BIO01 1MRB150005R1J will promptly trigger the protection mechanism to stop the equipment operation, prevent the production of unqualified products, and prompt the staff to perform equipment maintenance to ensure the continuity of production and product quality.

In food and beverage production factories, hygiene standards and production efficiency are equally important. ABB500BIO01 1MRB150005R1Jcan be used to monitor and control equipment such as filling machines, labeling machines, packaging machines, etc. It connects various sensors on the device, such as liquid level sensors, label position sensors, etc., to monitor the real-time operation status and product quality parameters of the equipment. During the operation of the filling machine, this module precisely controls the filling volume based on the feedback signal from the liquid level sensor, ensuring that the capacity of each bottle of product is consistent; When operating the labeling machine, ensure that the label is accurately attached to the designated position of the product based on the signal from the label position sensor. In addition, it can also be linked with the factory’s automated cleaning system to control the cleaning equipment during production intervals to quickly and thoroughly clean the production line, meeting the strict hygiene requirements of the food and beverage industry. Once the equipment malfunctions or there are quality issues with the product, such as excessive deviation in filling volume or weak labeling, ABB 500BIO01 1MRB150005R1J will immediately issue an alarm and take corresponding measures, such as suspending the production line to avoid the production of a large number of unqualified products and ensure the safety and efficiency of food and beverage production.

500BIO01 1MRB150005R1JRelated products:

ABB 500BIO02 1MRB150006R1J: an upgraded version of the same series, with significant improvements in data processing speed, communication functions, and the number of input and output channels. It is suitable for large-scale complex industrial automation projects that require extremely high control accuracy, response speed, and system scalability. The automated production system of a large steel plant requires processing a large number of equipment signals and complex control logic. This upgraded module can better cope with this and ensure the efficient and stable operation of the production process.

ABB 500BIO01S 1MRB150005R1JS: an economical version with simplified functions, retaining core control and monitoring functions, suitable for small industrial automation scenarios with relatively simple functional requirements and limited budgets. For example, the simple automated production line of a small clothing processing factory only needs to implement basic equipment start stop and status monitoring. This economical module is sufficient to meet its needs and provide an affordable automation solution for enterprises.

ABB DI810: Digital input module, compatible with ABB 500BIO01 1MRB150005R1J. Input the on-site digital signals, such as the start stop status and switch position signals of the equipment, into the 500BIO01 module to provide basic equipment operation status information. Together with analog data, they form a complete equipment operation monitoring system, achieving comprehensive monitoring and control of industrial processes.

ABB AO810: Analog output module, receives control signals processed from ABB 500BIO01 1MRB150005R1J, converts digital signals into analog outputs, and is used to adjust continuously changing control objects such as frequency converters and valve openings. Collaborate with the 500BIO01 module to complete the complete industrial automation control process from signal acquisition, processing to control output, achieving precise control of industrial production processes.

ABB PM851/PM851A: Processor unit module that works in conjunction with 500BIO01 1MRB150005R1J to further enhance the computing and control capabilities of automation systems. Responsible for executing more complex control algorithms, deeply optimizing and controlling industrial production processes based on data collected by the 500BIO01 module and system preset logic, and jointly building an efficient and intelligent automation control system with 500BIO01 1MRB150005R1J to improve the overall performance and intelligence level of the system.

ABB AC500-EC: Programmable Logic Controller, jointly built with ABB 500BIO01 1MRB150005R1J to create a complete automation control system. Realize comprehensive control of industrial production processes, covering various functions such as logic control, sequence control, and process control. The combination of the two can flexibly program complex control tasks according to different industrial scenario requirements. The control function of 500BIO01 module is closely integrated with the logical computing ability of PLC, providing a powerful control solution for industrial automation.

ABB PFEA113-50: commonly used in the field of power monitoring and control. When combined with this module, it can achieve power quality monitoring, power parameter analysis, and control of industrial power systems. Ensure stable and reliable power supply, such as real-time monitoring of voltage, current, power factor and other parameters, timely detection of power abnormalities and taking measures to ensure the normal operation of industrial equipment, providing stable power guarantee for 500BIO01 1MRB150005R1J and the entire automation system. At the same time, work together with 500BIO01 module to optimize the efficiency of power use in industrial production processes and reduce energy consumption.

500BIO01 1MRB150005R1J

Installation and maintenance:

Before installing ABB 500BIO01 1MRB150005R1J , it is necessary to thoroughly check the available space of the control cabinet to ensure that there is sufficient space around the module for heat dissipation and subsequent maintenance operations after installation, in order to avoid affecting module performance and maintenance convenience due to space constraints. Carefully check the grounding system of the control cabinet to ensure that it is firmly and reliably grounded. Good grounding can effectively avoid the impact of static electricity accumulation and electrical interference on module signal transmission and control performance, ensuring the accuracy and stability of data acquisition and command output. At the same time, strictly follow the electrical specifications to confirm that the power line specifications of the connected module are appropriate, ensuring that the power supply can stably provide the power required by the module, and avoiding abnormal module operation caused by insufficient power supply or voltage fluctuations. When connecting communication lines, ensure that the cables are firmly connected and well shielded to avoid interference during signal transmission.

During daily maintenance, it is recommended to conduct regular visual inspections of the module every month to check for any abnormal phenomena such as loose components, damaged casings, overheating, discoloration, etc., and promptly identify and address potential issues. Every quarter, ABB’s professional diagnostic software is used to conduct comprehensive functional testing on the module, checking whether the input and output channels are normal, whether the signal processing is accurate, and whether the communication connection is stable, to ensure that the module is always in good operating condition. Closely monitor the firmware update information released by ABB, conduct regular firmware upgrades based on actual usage and system compatibility assessments, obtain new features, optimize performance, and fix security vulnerabilities through upgrades, ensuring that modules continue to provide strong support for the stable operation of industrial automation systems. At the same time, establish a comprehensive maintenance record file to record in detail the time, content, problems discovered, and results of each maintenance, in order to facilitate subsequent analysis and evaluation of equipment operation status.

Other ABB brand models:

ABB 1KHL178025R0102P COM02

ABB 1MRB150005R1/P

ABB 1MRK000005-380 REG670

ABB 1MRK000508-BD

ABB 1MRK000508-CDr09

ABB 1MRK002122-ABR02

ABB 1MRK002238-CA

ABB 1MRK002311-AAR02

ABB 1MRK002311-AAR02

ABB 1MRK002816-AC

ABB 1MRK004810 RED670

ABB 1MRK004816-AB RET670

ABB 1SAJ520000R0101 1SAJ520000R0101 UMC100-FBP.0 A4

ABB 1SCA022079R9050

ABB 1SCA022079R9050 OETL-ZT80A220AC

ABB 1SDA-051116-R1

ABB 1SDA060537R1

ABB 1SDA071666R1

ABB 1SFA619550R1071

ABB 1SVR730830R0400

ABB 1SVR730840R0300

ABB 1TGB302004R5003

ABB 1TGE120011R1000

ABB 1TGE120011R1001

ABB 1TGE120011R1111

ABB 1TGE120021R0010

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626