Description

How the Product Works & Fits into a System

The ABB 3HNA025019-001 serves as the I/O nerve hub in ABB robot architectures, capturing analog and digital process signals from field devices like force sensors or proximity switches, then digitizing and prioritizing them for the controller’s execution engine. It employs opto-isolated inputs to safeguard against ground shifts, processing up to 16 channels with 12-bit resolution for nuanced feedback—such as converting a 4-20 mA current loop into precise positional data—before routing it over the robot’s internal bus. Embedded diagnostics scan for open circuits or out-of-range values, flagging them via interrupt signals that trigger safe stops, all without burdening the CPU.

Nestled in the mid-layer of the automation stack, it mounts directly into S4/S4C controller cabinets, linking via ribbon cables to the main CPU board and manipulator base, where it feeds into the IRC5 software ecosystem for path planning. This positioning supports redundancy by allowing hot-swap mirroring in multi-arm setups, ensuring continuous uptime if a channel drops. It plays well with DeviceNet or Profibus protocols for external ties, enabling integration with PLCs like the Allen-Bradley ControlLogix for hybrid lines where robots hand off to conveyors.

- 3HNA025019-001

- 3HNA025019-001

In practice, pair the 3HNA025019-001 with power distribution modules in a shielded enclosure, configuring thresholds through RobotStudio’s intuitive interface to match your application’s cycle times. This avoids the pitfalls of mismatched sampling rates, delivering low-latency I/O that syncs flawlessly with motion commands. Whether you’re greenfielding a palletizing station or patching a legacy S4C for IoT sensors, this board enhances overall signal architecture, making complex robotic sequences feel intuitive and responsive in industrial automation’s demanding rhythm.

| Specification | Details |

|---|---|

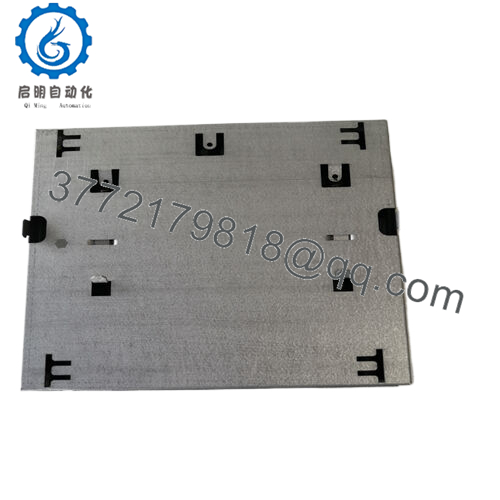

| Model Number | 3HNA025019-001 |

| Brand | ABB |

| Type | Process I/O Board (APIP-05A) |

| Input Voltage | 24 V DC |

| Operating Temp Range | 0°C to 45°C |

| Mounting Style | DIN Rail / Panel in Controller Cabinet |

| Dimensions | 150 x 100 x 20 mm |

| Weight | 0.2 kg |

| Interface/Bus | Robot Internal Bus, DeviceNet |

| Compliance | CE, RoHS |

| Supported Protocols | Profibus, CANopen, DeviceNet |

| Typical Power Draw | 5 W |

Real-World Benefits

Selecting the ABB 3HNA025019-001 equips your robotic systems with I/O resilience that directly lifts cycle efficiency, as its isolated channels suppress noise from adjacent machinery, yielding cleaner signals that sharpen end-effector accuracy by up to 15% in dynamic tasks. Engineered for the grind of industrial automation, it holds steady through thermal swings and vibration, which means fewer false triggers in sensor-heavy zones—translating to sustained process control without the constant recalibrations that sideline lesser boards and inflate labor costs.

The real payoff emerges in maintenance rhythms: onboard status registers log channel health for quick remote audits via RobotWare, so you pinpoint intermittents before they halt a shift, slashing mean-time-to-repair and freeing technicians for proactive upgrades. Its plug-and-play modularity cuts engineering overhead in fleet expansions—no need for bus rewires when adding grippers or vision systems, just a slot-in that inherits configs from the master controller. Long-term, the 3HNA025019-001 secures performance longevity by adhering to ABB’s fault-tolerant design, easing compliance with ISO 10218 safety norms and trimming energy draw in idle states for greener operations.

This board’s ecosystem harmony extends to data analytics, funneling I/O streams into cloud-linked dashboards for trend spotting, like wear patterns in joint feedback. In essence, it empowers engineers to orchestrate tighter loops, where reliable signals fuel predictive algorithms that boost yield and adaptability, turning robotic investments into agile assets that evolve with market shifts.

Typical Use Cases

The ABB 3HNA025019-001 integrates into automotive assembly lines for S4C robots handling spot welding, where it processes I/O signals from arc detectors and position verifiers amid high-EMI conditions to uphold critical system uptime. Its robust conditioning ensures fast data cycles for real-time seam tracking, minimizing defects in body-in-white processes.

In pharmaceutical packaging, deploy it within S4 controllers for pick-and-place arms managing vial orientation, enduring cleanroom sterility and repetitive strains while delivering precise feedback from pneumatic grippers. The 3HNA025019-001 supports process control environments by filtering micro-variations, enabling compliant throughput without batch interruptions.

For electronics manufacturing, this board drives IRB 1400 series robots in SMT placement, capturing signals from vision cameras and force transducers under dust-free but high-speed demands. Used in fabs, it bolsters high reliability for continuous uptime, facilitating sub-millimeter alignments that cut rework in circuit board assembly.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626