Description

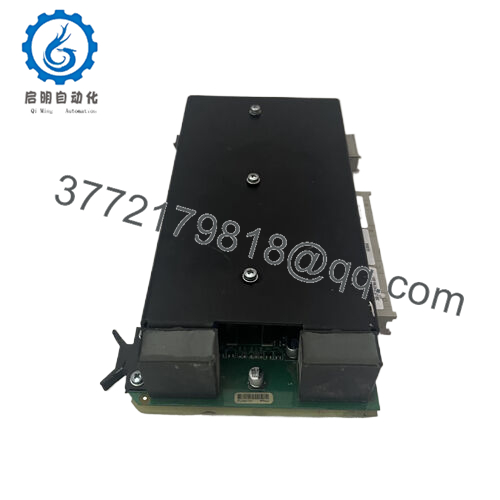

ABB 3BUS208796-501 is a professional industrial communication protocol conversion module and an important member of ABB’s industrial automation product system. It is compatible with ABB’s advanced automation control system architecture, connecting various equipment nodes like an information hub throughout the entire system.

ABB 3BUS208796-501

By connecting with various sensors, actuators, controllers, etc., it receives data signals in different formats from field devices, converts and processes them according to preset protocols, and accurately transmits the processed data to the corresponding devices or systems. For engineers and system integrators, its advantages are significant. It has strong compatibility and can easily integrate into existing or newly built automation networks, reducing technical difficulties and cost investment during system upgrades and renovations. Moreover, communication protocols and parameters can be flexibly configured according to the communication needs of different projects, meeting diverse industrial communication scenarios and laying the foundation for building a stable and efficient automated communication network.

ABB 3BUS208796-501

Main features and advantages:

In terms of functional performance, ABB 3BUS208796-501 has excellent data processing and transmission capabilities. It can transmit data at high rates, greatly reducing communication latency and ensuring real-time monitoring and control in industrial processes. When dealing with complex communication tasks, it has high stability and can continue to work stably even in the face of common problems such as power fluctuations and electromagnetic interference in industrial environments, ensuring the accuracy and integrity of data transmission. Its intelligent error detection and correction mechanism can timely detect and process errors in data transmission, reducing the risk of production accidents caused by communication errors.

In terms of hardware design, the module is made of sturdy and durable materials, which can adapt to harsh conditions such as vibration, impact, high temperature, and high humidity in industrial environments, ensuring long-term reliable operation. The compact size design allows it to be flexibly installed in various control cabinets or equipment with limited space. At the same time, an easy to operate installation method is adopted, such as the common DIN rail installation, which facilitates quick installation and layout adjustment on site.

Compatibility is a major highlight of ABB 3BUS208796-501. It supports communication protocols widely used in various industrial fields, such as Modbus, Profibus, Ethernet/IP, etc. This means that it can seamlessly integrate with different brands and types of industrial equipment, achieve interconnectivity of the entire automation system, break down communication barriers between devices, and facilitate the construction of large-scale and complex industrial control networks.

In terms of long-term reliability, the module has been carefully designed. Having a good heat dissipation structure, it can effectively dissipate heat during long-term high load operation, maintain the appropriate working temperature of internal electronic components, thereby extending the service life of components and ensuring long-term stable operation of the module. Moreover, strict quality inspection and aging testing are carried out before leaving the factory to ensure the reliability and stability of the product in actual use from the source, reducing maintenance costs and equipment downtime.

ABB 3BUS208796-501

Technical specifications:

Model 3BUS208796-501

Brand ABB

Type Industrial Communication Protocol Conversion Module

The power supply is adapted to various power specifications according to specific application scenarios

Working temperature -20 ° C to 70 ° C

Installation method: DIN rail installation

Supports various communication protocols such as Modbus, Profibus, Ethernet/IP, etc

Certification complies with relevant international certification standards such as CE and UL

Natural convection combined with heat sink assisted heat dissipation method

Environmental grade IP20, can resist a certain degree of dust, suitable for general industrial environments

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

ABB 3BUS208796-501

Application areas:

In the field of industrial automation control systems, it plays an irreplaceable role. In terms of PLC (Programmable Logic Controller) network connection, with the help of ABB 3BUS208796-501, different PLCs can achieve data exchange and collaborative operation. For example, in the automated production line of an automobile manufacturing factory, multiple PLCs communicate through this module to accurately control the grasping, handling, and assembly actions of the robotic arm, optimize the entire production process, ensure close coordination in every link, and improve production efficiency and product quality. In SCADA (Supervisory Control and Data Acquisition) systems, it facilitates the integration of various remote monitoring devices. Taking petrochemical enterprises as an example, through this module, operators can obtain real-time key operating data such as temperature, pressure, and flow rate of production equipment, discover and handle potential problems in a timely manner, and improve production safety and efficiency.

In the scenario of intelligent manufacturing and device interconnection, ABB 3BUS208796-501 also performs well. In the electronic product manufacturing workshop, production line equipment relies on it for communication and data transmission, achieving intelligent production scheduling and real-time data monitoring. When market demand changes, the production system can use this module to quickly adjust production plans, arrange equipment operation reasonably, reduce production cycles, and respond quickly to the market. In the robot control system, it is the bridge that ensures efficient communication between the robot and the control system, sensors, and actuators. In logistics and warehousing automation, collaborative robots receive control instructions through this module, interact with sensor feedback data, and accurately complete the sorting and handling of goods, ensuring the coordinated and orderly work of automated production systems.

In the smart grid system, the value of this module is also very prominent. It promotes efficient data exchange between equipment such as substations and distribution networks, providing support for power flow optimization, load management, and more. By monitoring the parameters of the power grid in real-time, intelligently allocating power resources based on peak and valley electricity consumption, reducing energy consumption, and improving the stability of power grid operation. In sewage treatment facilities, it is responsible for data communication between sensors and monitoring systems. Real time detection of parameters such as water quality, flow rate, and chemical composition. Once the water quality does not meet the standards or the equipment operates abnormally, the monitoring system can receive signals in a timely manner and take appropriate measures to ensure the safety and compliance of the sewage treatment process. In the environmental monitoring system, whether it is an air quality monitoring station or a noise monitoring point,3BUS208796-501 supports real-time collection and remote transmission of environmental parameters, allowing environmental management departments to timely grasp environmental dynamics and provide data basis for environmental protection decisions. In the intelligent transportation management system, devices such as traffic lights, cameras, and sensors use it to achieve data communication, optimize traffic flow, and ensure smooth and safe road traffic.

ABB 3BUS208796-501

Related products:

ABB 3BUS208796-001: Relatively simple in function, suitable for small industrial automation projects with low communication function requirements and limited budget.

ABB 3BUS208797-001: Improved in data processing speed and communication stability, more suitable for large and complex industrial automation systems, to meet the needs of large data transmission and high-frequency communication.

ABB DI803: Digital input module, can be used in conjunction with ABB 3BUS208796-501 to input on-site digital signals into the automation system, achieving monitoring of equipment status, such as detecting the start stop status of motors, valve opening and closing status, etc.

ABB AO610: Analog output module, receives processed signals from ABB 3BUS208796-501, outputs analog control signals, used to adjust continuously changing control objects such as frequency converter and valve opening.

ABB PM851/PM851A: Processor unit module, working in conjunction with 3BUS208796-501, enhances the computing and control capabilities of automation systems, responsible for executing complex control algorithms and controlling the overall system operation logic.

ABB AC500-EC: Programmable logic controller, together with ABB 3BUS208796-501, to build a complete automation control system, achieving comprehensive control of industrial production processes, covering various functions such as logic control, sequence control, process control, etc.

ABB PFEA113-50: commonly used in the field of power monitoring and control. When combined with this module, it can achieve power quality monitoring, power parameter analysis and control of industrial power systems, ensuring stable and reliable power supply.

Installation and maintenance:

Before installing ABB3BUS208796-501, it is necessary to thoroughly check the available space of the control cabinet to ensure that there is sufficient space around the module installation for heat dissipation and subsequent maintenance operations. Carefully check the grounding system of the control cabinet to ensure that it is firmly and reliably grounded, effectively avoiding the impact of static electricity accumulation and electrical interference on the communication performance of the module. At the same time, strictly follow the electrical specifications and confirm that the power line specifications of the connected module are appropriate, which can stably provide the power required by the module and avoid abnormal operation of the module due to power problems.

During daily maintenance, it is recommended to conduct regular visual inspections of the module every month to check for any abnormal phenomena such as loose components, damaged casings, overheating, and discoloration. Every quarter, ABB’s professional diagnostic software is used to conduct comprehensive functional testing on the modules, checking whether the communication connection is normal, whether the protocol conversion is accurate, and whether there are any packet loss issues during data transmission. Pay close attention to the firmware update information released by ABB, conduct regular firmware upgrades based on actual usage and system compatibility assessments, in order to obtain new features, optimize performance, and fix security vulnerabilities, ensuring that modules always maintain optimal operating conditions and provide strong support for stable communication in industrial automation systems.

Other ABB brand models:

ABB 1KHL178025R0102P COM02

ABB 1MRB150005R1/P

ABB 1MRK000005-380 REG670

ABB 1MRK000508-BD

ABB 1MRK000508-CDr09

ABB 1MRK002122-ABR02

ABB 1MRK002238-CA

ABB 1MRK002311-AAR02

ABB 1MRK002311-AAR02

ABB 1MRK002816-AC

ABB 1MRK004810 RED670

ABB 1MRK004816-AB RET670

ABB 1SAJ520000R0101 1SAJ520000R0101 UMC100-FBP.0 A4

ABB 1SCA022079R9050

ABB 1SCA022079R9050 OETL-ZT80A220AC

ABB 1SDA-051116-R1

ABB 1SDA060537R1

ABB 1SDA071666R1

ABB 1SFA619550R1071

ABB 1SVR730830R0400

ABB 1SVR730840R0300

ABB 1TGB302004R5003

ABB 1TGE120011R1000

ABB 1TGE120011R1001

ABB 1TGE120011R1111

ABB 1TGE120021R0010

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626