Description

In the intricate web of industrial automation, where disparate legacy controllers and modern field devices must converse without a stutter, engineers often contend with the ghosts of incompatible protocols, fragmented data streams, and integration snags that turn routine expansions into protracted ordeals. Envision a legacy power plant retrofitting Advant systems with Ethernet-savvy sensors—mismatched communication layers could fragment turbine monitoring feeds, spawning delays that skew load balancing and invite thermal excursions with steep repair tabs. Or contemplate a chemical facility’s DCS, laced with older AC160 units amid corrosive vapors, where signal silos lead to dosing errors, eroding batch purity and compliance standings in an era of tightening emissions regs. These frictions aren’t anomalies; they’re the entrenched hurdles in process control ecosystems, demanding high reliability in I/O signal bridging to sustain the fluid handoffs that underpin operational cadence.

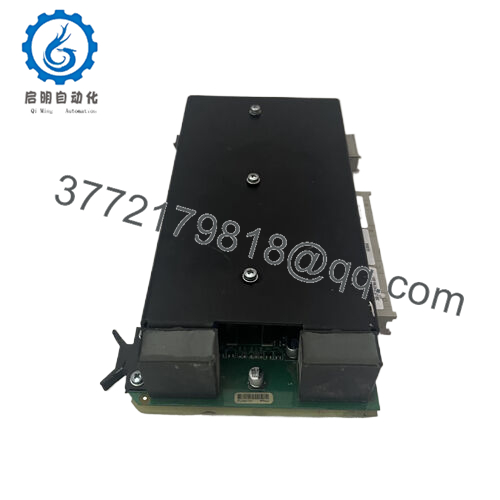

Here, the ABB 3BUS208796-501 asserts itself as a pivotal communication module, honed for ABB’s Control IT and Advant lineages to forge unyielding links across protocol chasms. It confronts the engineer’s quest for cohesive data orchestration, translating Modbus RTU pulses or serial handshakes into Ethernet/IP fluency, so field inputs cascade seamlessly to central hubs without the scourge of dropped packets or reconfiguration marathons. In bridging scenarios—like syncing legacy exciters in hydro stations or fusing analog loops with digital overlays in batch reactors—the ABB 3BUS208796-501 stands as indispensable, its compact footprint enabling drop-in upgrades that preserve rack real estate while amplifying network throughput. By prioritizing interference-hardened transceivers and auto-negotiation smarts, it quells the engineering drag of gateway farms, channeling pristine I/O signals to elevate system responsiveness and sideline the downtime that audits flag.

What distinguishes the ABB 3BUS208796-501 in industrial automation isn’t overt flair, but its surgical focus on interoperability’s subtleties—where it doesn’t merely connect but contextualizes, embedding timestamping for event correlation that sharpens fault forensics without taxing host CPUs. For outfits navigating DCS migrations, it dissolves the opacity of mixed-vendor tie-ins, supporting OPC DA for visualization layers that render legacy silos transparent. In sum, it cultivates process control that’s not just linked but luminous, trimming the latency where discrepancies fester and fortifying the high reliability your throughput metrics crave.

The ABB 3BUS208796-501 resides in the connective nexus of your automation stack, straddling field-level terminations and controller backplanes to mediate data dialogues in ABB’s AC800M or Advant enclosures. It ingests serial or fieldbus ingress from remote I/O drops—say, RS485 from valve positioners—then modulates it via onboard buffers into TCP-wrapped payloads for Ethernet spines, ensuring cycle-sync across domains with jitter under 5ms. In a hybrid rack, it clips to the S800 I/O bus, interfacing with baseplates like the BB810 for channel fanning, while dual RJ45 ports sustain ring redundancy to weather link snaps without loop interruptions.

Its interplay with cohorts is intuitive: pair it with CI853 modules for Profinet uplifts, and it arbitrates address resolutions on the fly, while diagnostic relays pulse alerts to HMIs on buffer overflows or cable faults. Built for edge deployment in remote cabinets, the ABB 3BUS208796-501 leverages ABB’s System 800xA tools for parameter scripting—tweak baud rates or parity once, and it’s propagating configs downstream sans manual polls. Redundancy manifests in failover paths that mirror traffic, and its protocol stack—spanning Modbus TCP to DNP3—eases grafts onto SCADA overlays. For transitional architectures blending Advant relics with IP cores, it curtails custom scripting, positioning you to refine control narratives over wrangling wires.

- ABB 3BUS208796-501

- ABB 3BUS208796-501

| Specification | Details |

|---|---|

| Model Number | 3BUS208796-501 |

| Brand | ABB |

| Type | Communication Module |

| Input Voltage | 24 V DC |

| Operating Temp Range | -20°C to +60°C |

| Mounting Style | DIN Rail / Backplane |

| Dimensions | 120 x 90 x 45 mm |

| Weight | 0.4 kg |

| Interface/Bus | RS485 / Ethernet |

| Compliance | CE, RoHS, IEC 61850 |

| Supported Protocols | Modbus RTU/TCP, DNP3, OPC DA |

| Typical Power Draw | 4 W |

Embracing the ABB 3BUS208796-501 infuses your infrastructure with a reliability ethos forged for the flux of evolving networks, where its noise-immune pathways preserve packet wholeness through EMI storms or voltage sags, begetting the performance consistency that stabilizes loops and averts the yield dips from desynced feeds. In protocol-melding zones like control rooms abuzz with hybrid cabling, this yields to operators who lean on unified views, unmarred by the artifacting that plagues ad-hoc bridges—directly curbing event-driven halts and honing the precision your KPIs exalt.

The assimilation advantages accrue subtly yet substantially, lightening engineering overhead via one-shot firmware flashes that ripple to peripherals, so scaling from 10 to 100 nodes unfolds as a config tweak, not a teardown saga. Engineered for the span of DCS lifecycles, the ABB 3BUS208796-501 instills maintenance finesse through heartbeat pings that herald link degradations, elongating probe cadences and rechanneling labor from crisis dives to strategic audits. In the grander scheme, it nurtures an automation tapestry primed for augmentation, where appending IIoT sensors amplifies insight sans eroding foundational sync, vouchsafing long-term performance that harmonizes with fiscal foresight and adaptive vigor.

In utility control centers, the ABB 3BUS208796-501 knits legacy Advant relays to modern Ethernet SCADA, shuttling substation status updates for grid harmony amid peak surges—its protocol agility upholds critical system uptime in process control realms where fractional-second lags invite blackouts, folding into 800xA for holistic vigilance. Petrochemical complexes enlist it for reactor oversight, coupling AC160 loops with fieldbus sensors to track pH drifts; here, high reliability thwarts vapor-induced glitches, enabling seamless data cycles that safeguard batch sanctity without sentinel patrols.

Renewable energy parks complete the triad, deploying it in inverter farms to merge serial trackers with IP historians for yield optimization under variable winds—the module’s redundancy steels against transient outages, anchoring continuous uptime in dispersed process control environments that prize resilience over reach.

3BUS208799-001 – Compact successor with native Profinet for streamlined fieldbus migrations.

CI853A02 – Profinet IO device module, complementing Ethernet uplifts in AC800M setups.

FBOO11 – Fiber optic variant for EMI-vulnerable long-haul communications.

3BSE030221R1 CI854 – Foundation Fieldbus linker, ideal for hazardous area extensions.

DO801 3BHE014070R0001 – Discrete output pair for protocol-bridged alarm routing.

PM864A 3BSE018161R1 – Processor base for hosting communication stacks in core racks.

TU810V1 3BSC120063R8 – Terminal unit add-on for secure field wiring in remote drops.

As you ready the ABB 3BUS208796-501 for rack insertion, scrutinize bus termination against ABB’s topology charts—unmatched impedances breed reflections that hash data, so ohm out stubs pre-commit. Vet enclosure ingress too; its ports demand IP54 seals in steamy bays, with 30mm clearances for convective cooling if loads nudge 60°C—cross with your HVAC logs for margin. Firmware parity seals the prep: harvest the current build from ABB’s vault, align to your host revision, and stage a loop test on a shadow net to vet handshake vigor before live infusion.

In the operational groove, stewardship skews toward acuity over abundance. Bimensual ledger pulls via engineering port can unmask latency spikes, spurring a targeted cable audit for attenuation. Semiannually, swab connectors with dielectric grease to fend off creep in humid climes, and cinch to 0.4 Nm amid vibrational theaters. Cap it with a yearly protocol sweep: emulate traffic bursts, recal if throughput dips below 95%, and archive for drift diagnostics like creeping jitter. These maneuvers harness the module’s telemetry to perpetuate your industrial automation’s pulse, rendering upkeep an ally rather than an adversary.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626