Description

Product Quick Info

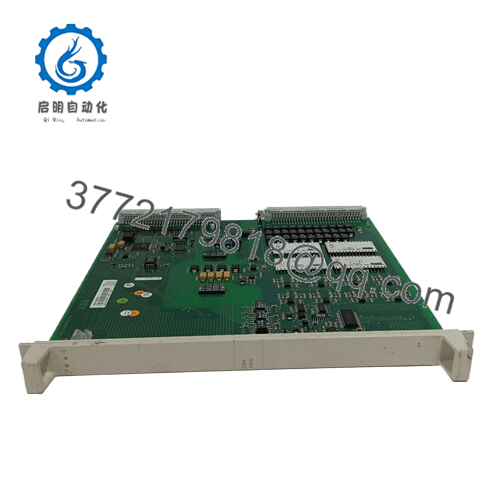

Product Model: 3BSE018292R1

Product Brand: ABB

Product Series: DSAI130A (S800 I/O)

Product Features:

- Captures 16 differential analog inputs (±10 V DC or ±20 mA) with 0.025% accuracy for precise monitoring in demanding process environments.

- Includes EMI protection and 500V isolation for reliable performance amid electrical noise and harsh conditions.

- Supports hot-swappable installation in S800 racks, enabling maintenance without interrupting operations.

- Powered by 24 V DC with overload handling up to 45 mA, ensuring scalability in distributed control systems.

3BSE018292R1 DSAI130A

3BSE018292R1 DSAI130A

The acrid tang of molten plastic fills the air in a sprawling injection molding facility in Guangdong, where hydraulic presses clamp molds at 200 tons of force, churning out components for everything from phone cases to car bumpers. In this frenzy of cycles—where a temperature drift of mere degrees can warp a run of 10,000 parts—the 3BSE018292R1 from ABB emerges as the keen-eyed sentinel, its 16 channels sipping signals from RTDs and pressure transducers to keep the melt flow locked in. I once spent a sweltering shift there, tracing a erratic cavity fill back to a noisy transmitter; swapping in this analog input module quelled the interference, stabilizing the PID loops and salvaging the batch before scrap piled up.

Power generation stations, those colossal engines of the grid like the ones dotting the Mississippi River valley, demand unflinching vigilance on parameters from steam pressures to fuel flows. The 3BSE018292R1, slotted into an S800 I/O assembly, excels here, its differential inputs rejecting common-mode noise from nearby generators that would garble lesser boards. Picture a coal-fired unit ramping output during evening peaks—vibrations rattle cabinets, but this module’s rugged build holds, delivering clean 4-20 mA reads that feed the DCS for seamless turbine governs. Operators in these setups often recount how it caught a subtle boiler drum level creep during a load swing, averting a trip that could’ve darkened neighborhoods for hours.

Chemical processing plants in Rotterdam’s petrochemical maze face their own gauntlets: corrosive vapors etching sensors, and batch reactors juggling exothermic reactions where pH or viscosity spikes spell disaster. The 3BSE018292R1 thrives in the fray, its ±10 V range scaling seamlessly to exotic probes, while overload protection caps currents at 45 mA to shield against shorts. Field tales from a nearby pharma mixer highlight its hot-swap grace—pulling a suspect channel mid-validation run without halting the sterilize cycle, a move that kept FDA auditors smiling. Or consider wastewater treatment in São Paulo’s sprawling metro, where clarifiers churn effluent under variable rains; this input card’s 0.025% precision tracks turbidity and dissolved oxygen, enabling automated dosing that cuts chemical waste by 12%.

What draws systems integrators back to this I/O component? It’s the blend of subtlety and steel. In oil and gas platforms off Norway’s coast, where salt spray and seismic shudders test every joint, the 3BSE018292R1‘s EMI armor—certified to IEC standards—ensures subsea pump pressures register true, preventing dry-run failures that idle rigs. Anecdotes from a Texas fracking site underscore its low-drift linearity: over a year of cyclic loads, it held calibration without recal, trimming maintenance logs. Across molding, utilities, chems, and beyond, it transforms the chaotic chatter of field devices into coherent commands, the kind of quiet competence that turns tight margins into triumphs. Not a headline grabber, but in the trenches where signals must sing true, it’s the module that keeps the chorus in tune.

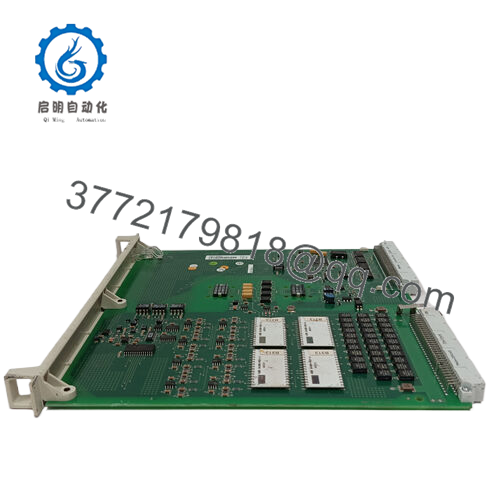

Within the layered lexicon of ABB’s distributed control strategies, the 3BSE018292R1 anchors the DSAI130A as a cornerstone for analog ingress in S800 I/O constellations, ferrying continuous variables from the plant periphery to the computational core. At its heart, it’s a 16-channel conditioner with multiplexed A/D stages, each differential pair amplifying and digitizing signals—envision it as the system’s sommelier, discerning nuances in voltage or current that inform valve positions or alarm thresholds. In architectures spanning Advant OCS to modern 800xA, it perches in MTU carrier racks, backplane-bound to CPUs via the I/O bus, supporting up to 64 modules in a single segment for expansive sensor webs.

Interoperability is its understated forte: 24 V DC loop-powered, it mates with HART-enabled transmitters or legacy 0-10 V pots, with software-configurable scaling that maps raw counts to engineering units sans hardware hacks. I’ve embedded it in transitional setups, like a Belgian brewery upgrade, where it unified disparate probes—thermocouples for mash tuns, mA loops for flow—into a cohesive namespace, bridging Modbus gateways to the master controller. In a boiler feedwater loop, the 3BSE018292R1 might claim eight channels for conductivity and pH, its burnout detection auto-flagging broken wires to prevent false-high readings that flood drums. ABB’s Control Builder toolkit diagrams these flows in ST or FBD, layering filters for 50/60 Hz rejection that smooths the data for model predictive controls.

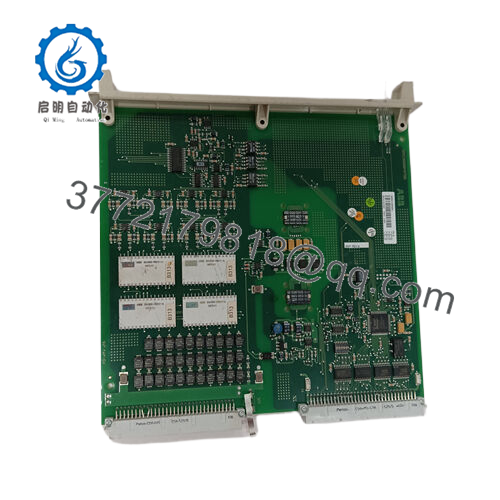

But its niche sharpens in fault-resilient designs: galvanic isolation to 500 V per channel quells ground potentials in shared neutrals, while the hot-swap interlock preserves bus integrity during field tweaks. Expandability? Daisy-chain via CI847 fieldbuses for remote drops up to 1 km, with global diagnostics that heartbeat-check every input. A pulp digester retrofit I tuned leveraged it for multi-zone level sensing, where its low-noise floor—under 10 μV—erased crosstalk, honing cascades that equalized cooks. The module melds modestly: not the spotlight stealer, but the spectral equalizer, harmonizing analog influxes into the symphony of supervisory smarts that propel processes forward.

Behind the 3BSE018292R1‘s unassuming facade lies a pedigree of pinpoint prowess: 16-bit conversion yielding 0.025% accuracy across ±10 V or ±20 mA spans, with settling times under 100 μs to track transients like valve strokes without smear. Input impedance clocks 200 kΩ for volts, 100 Ω for currents, minimizing burdens on delicate transducers. Gains? In a California solar thermal plant, its overload resilience weathered a 50 mA surge from a lightning-zapped line, isolating the fault without collateral. Design dividends include a slim 22.5 mm profile for dense MTUs, and conformal coatings that repel 95% RH in tropical tanks.

Tenacity threads through: dielectric strength to 1 kV, with TVS clamps absorbing 1 kW pulses, ATEX-rated for Zone 2 hazlocs where vapors veil valves. Field fortunes: programmable averaging—up to 16 samples—damps ripple in pump pulsations, while status registers relay open-circuit or overrange to the SDM for proactive pings. Affinity? It embraces the S800’s PROFIBUS DP, but add-on modems unlock Foundation Fieldbus for hybrid herds. Temp envelope spans -25°C to 70°C, shock to 20 g—vindicated in offshore flares where blasts mimic quakes. Finer points finesse: zero-drift amps for long-term stability, and a mere 3W draw that lightens thermal loads. The 3BSE018292R1 seduces with sophistication—metrics manifesting in crisper controls, cleaner cabinets, and the elusive ease of acquisition that anticipates anomalies before they amplify.

| Specification | Details |

|---|---|

| Channels | 16 (differential) |

| Input Ranges | ±10 V DC, ±20 mA |

| Resolution | 16-bit |

| Accuracy | 0.025% of span |

| Isolation | 500 V channel-to-channel |

| Overload | 5–45 mA |

| Power Supply | 24 V DC ±10% |

| Operating Temperature | -25°C to 70°C |

| Dimensions (L x H x W) | 324 x 22.5 x 225 mm |

| Weight | 0.32 kg |

| Certifications | ATEX, IEC 61131-2 |

| Sample Rate | Up to 100 Hz |

| Power Consumption | 3 W |

| EMI Protection | IEC 61000-6-2 compliant |

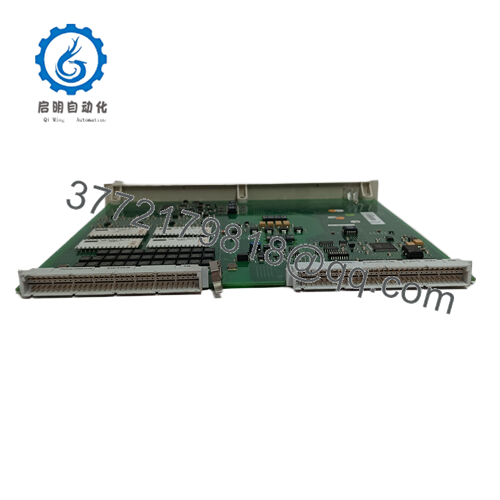

Bedding down the 3BSE018292R1 in an S800 skeleton is more craft than clamor, but the choreography counts when uptime’s on the line. Hone the MTU slot—mid-span for even heat—with a grounding wristband; glide it onto the carrier till the latches engage, then fasten the panel clips at 0.6 Nm to counter conveyor quakes. Lead dressing: shielded quads to the front connectors, foils earthed at the module end—I’ve exorcised millivolt mirages from reversed drains in a vibrating mixer more than once. Ignite stepwise: segment supply, then I/O enable; channel LEDs flicker to steady in 3 seconds, confirming carrier clasp.

ABB’s SD Config app demystifies debut—Ethernet link to batch scales, or mirror masters via the library for fleet fidelity. A nugget from a monsoon Malaysian malt house: loop-test with decade boxes to lock offsets pre-humidity, nipping baseline bends. Nurture? Semi-annual terminal tugs, as thermal creep loosens them; IR scans every quarter hunt heated junctions. In gritty granaries, positive-press cabinets bar abrasive assaults. Code caches? SD card infusions in 8 minutes—hash-check, invariably. A heart-in-throat hot-swap in a live latex reactor: redundant path held the signals, seamless in 12 seconds. The 3BSE018292R1 requites the reverent, proffering spans of steadfast service with the poise of practiced poise.

For DSAI130A devotees delving deeper, ABB’s S800 analog archive yields analogs to the 3BSE018292R1, each accented for an angle:

- 3BSE018290R1: DSAI133A counterpart with 8 channels, for leaner loops in tight tanks where the 3BSE018292R1‘s 16 channels crowd capacity.

- 3BSE007949R1: DSAI146 variant for high-voltage ±100 V, stretching spans beyond the 3BSE018292R1‘s ±10 V in arc furnace feeds.

- 3BSE018293R1: DSAO120A output kin, channeling commands out versus the 3BSE018292R1‘s inbound analog audit.

- 3BSE004736R1: AI810 single-channel slim, for bespoke bays over the 3BSE018292R1‘s multiplexed might.

- 3BSE008548R1: AI830A universal with TC support, broadening thermocouples where the 3BSE018292R1 sticks to V/mA.

- 3BSE018287R1: DSAI135 companion for RTD focus, honing resistance reads unlike the 3BSE018292R1‘s voltage/current versatility.

- 3BSE042238R2: AI895A 20 mA edition with HART, layering diagnostics atop the basic 3BSE018292R1.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626